I'm quite new to this, having bought a house in the countryside in southern Sweden. The previous owner invested a lot of time in the heating and hot water setup - with solar taking care of about 4 months of the year (hot water) and the rest with a wood burning furnace - a Swedish Nibe Vedex 3000 - which was installed in approx 2005. There is no English manual for this model however it is very similar to the replacement Vedex 3300 for which I have an English manual, so I believe I am operating it correctly.

We've been burning the furnace for about 2 months, for hot water only the first month and turned on the heating system about a month ago. Now with the outside temperature range of -2C to 7C each day, I'm burning it every evening for 3-4 hours (usually it's 1 full load of wood per day - mostly birch).

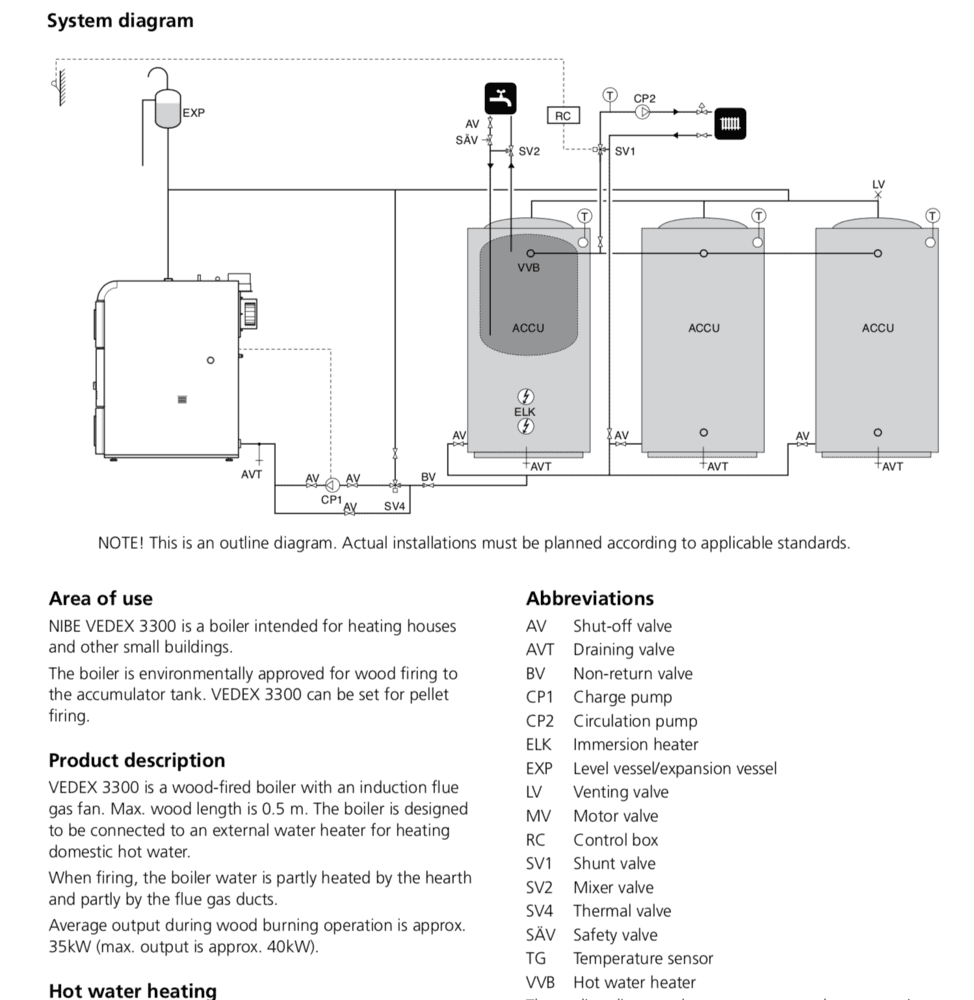

The system has 3 x 1000L accumulator tanks (it is quite a big house of 270m2 with around 200m2 being heated) with floor heating in about 1/3 of the house and radiators in the rest of the house (which is in 2 stories where the radiators are). Attached is the standard system diagram for this installation, which is what I believe we have installed.

I have a few questions.

1. There are 3 temperature gauges for the accumulator tanks (which are well insulated behind a fiber board wall so i have not inspected them) - and I am unsure if these are the temperatures for each of the tanks or the top/middle/bottom temperatures of the primary tank. Any ideas?

2. The burner normally operates with a flue temp of between 180-230C for the whole burn. By the end of the burn, the top accumulator temperature gauge reaches 90-100C, while the other two reach only around 50C. I burn in the evening (finishing around 11pm) and the 3 gauges reach an equilibrium by the next morning of around 50-60C - by which time we get a couple of warm showers in the morning, and heating is ok through the day. Is this normal or should the three gauges increase and decrease at the same rate? (i'm still unsure what they measure - see question 1!).

3. There is a ceramic grate (in 5 pieces which fit together) for the floor of the boiler (above the flame trough) which are due for replacement (there is quite a large hole in the middle which should not be there). Should replacing these be a top priority for efficient burning?

Thanks for any advice in advance! I quite like the whole exercise with this form of heating, which certainly makes me more conscious of ensuring we don't overheat the house or waste hot water

We've been burning the furnace for about 2 months, for hot water only the first month and turned on the heating system about a month ago. Now with the outside temperature range of -2C to 7C each day, I'm burning it every evening for 3-4 hours (usually it's 1 full load of wood per day - mostly birch).

The system has 3 x 1000L accumulator tanks (it is quite a big house of 270m2 with around 200m2 being heated) with floor heating in about 1/3 of the house and radiators in the rest of the house (which is in 2 stories where the radiators are). Attached is the standard system diagram for this installation, which is what I believe we have installed.

I have a few questions.

1. There are 3 temperature gauges for the accumulator tanks (which are well insulated behind a fiber board wall so i have not inspected them) - and I am unsure if these are the temperatures for each of the tanks or the top/middle/bottom temperatures of the primary tank. Any ideas?

2. The burner normally operates with a flue temp of between 180-230C for the whole burn. By the end of the burn, the top accumulator temperature gauge reaches 90-100C, while the other two reach only around 50C. I burn in the evening (finishing around 11pm) and the 3 gauges reach an equilibrium by the next morning of around 50-60C - by which time we get a couple of warm showers in the morning, and heating is ok through the day. Is this normal or should the three gauges increase and decrease at the same rate? (i'm still unsure what they measure - see question 1!).

3. There is a ceramic grate (in 5 pieces which fit together) for the floor of the boiler (above the flame trough) which are due for replacement (there is quite a large hole in the middle which should not be there). Should replacing these be a top priority for efficient burning?

Thanks for any advice in advance! I quite like the whole exercise with this form of heating, which certainly makes me more conscious of ensuring we don't overheat the house or waste hot water