Whitfield died?

- Thread starter Bugs

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

“Taking the basic problem simply : all the electrics worked fine until the new auger motor was fitted.

After that we have a toasted triac and fuse for each trial.”

Actually it blew the first time with the original auger motor, that’s what got me started on this quest to fix this beast.

After that we have a toasted triac and fuse for each trial.”

Actually it blew the first time with the original auger motor, that’s what got me started on this quest to fix this beast.

Mt Bob

Minister of Fire

I thought so,which is why I recommend the separate fuses.They are getting off on electronics theory,without having the device in hand,which is fine kinda fun reading it all,lol

Bugs can you take a pic of the 2 auger motor labels. Im curious of the amps they are drawing.

Attachments

Ssyko

Minister of Fire

Yes we kinda went off into left field but it was great exercise for my brain. But glad your back Bugs! Now you know what we all need to know is if the new auger motor has the same stats voltage, amps etc. as the old motor.

any in-line 120v 3or4 amp would work

Bought 3 inline and 5amp fuses should I use 4amp ?

Ssyko

Minister of Fire

Ssyko

Minister of Fire

Mt Bob

Minister of Fire

even less would be fine,2 or 3,but 4 is still less,is ok.Bought 3 inline and 5amp fuses should I use 4amp ?

Ssyko

Minister of Fire

Your fuses that blew were 5amp fast blow?

They where 6amp fast, that’s why I think Bob recommended going lower amp.

Okay, now I have to correct myself, the fuse did not blow with the old auger, it just stopped turning the auger (from what I remember) fuse blew with the new auger.“Taking the basic problem simply : all the electrics worked fine until the new auger motor was fitted.

After that we have a toasted triac and fuse for each trial.”

Actually it blew the first time with the original auger motor, that’s what got me started on this quest to fix this beast.

Bugs, just curious.

What is the auger clearance with the new bushing?

Where are you sourcing the board component?

Soon you will win!

It is much better 1/8” up/down virtually 0” side to side.

Digi-key for components

I'm surprised that the auger is using a triac : it must be speed controlled and not a duty cycle for which a relay would be more suited.

But 15 minutes sounds about right to toast a triac if you are overheating it.

what else could you use a triac for ?

The first time was about 45 min the second about 15.

I think there may be a pot in between for speed adjustment.

Since monday the internet has been down at my place ( cables were ripped over by some heavy machines down the road. ) But now it's working again

There seems to be some confusion about the number af triacs on Bugs' and my control boards. They are absolutely identical ( except for a few 230 Volt components needed on my board ).

I can inform you with absolute empirical certainty that there are only three triacs on the boards... two are for the blower motors and both these have heat sinks, since the blower motors run continously and have a higher wattage ( draw more amps ). The auger triac is the one without heat sink. The auger motor only draws 0.41 amps @ 120 Volt/60 Hz and is only meant to run intermittently controlled by a recycling routine written inside the microcontroller.

The three triacs on my board are all manufactured by Motorola and all three have the type designation: MAC 228 A6 ( sensitive gate ).

The fourth component, also in a TO220 housing like the triacs, is located close to the transformer and is a positive voltage regulator ( LM 7805 ) that supplies the microcontroller and its sourrounding components with 5 Volt DC

Overview, current consumption @ 120 Volt/60 Hz:

Combustion motor: 0.95 Ampère

Convection motor: 1.25 Ampère

Auger motor: 0.41 Ampère

Total: 2.61 Ampère

To this we must add transformer loss and the consumption of all the other components on the board. If the auger motor is restricted severely, it could easily draw more than the nominal 0.41 Ampère. I understand that Bugs is running the stove with a 3 A Fast acting fuse, since there's no igniter installed, so from this calculation we can conclude that a 3 A fuse is working on its limits in a restricted auger situation.

But why is the triac melted into a short every time the fuse blows? A possible answer to this question could be to know these exact informations: We need to know both the exact time for the climax in current rise through the auger triac and the exact time of the climax of the torgue produced by the auger motor. From what Bugs informed us in a previous post, the loud "bang" noise from the auger occurred simultaniously with the fuse popping. This information led me to conclude that the source of the issue was a restricted auger shaft.

Bugs: Try a 6 A fuse instead. Mine has been running with the same 6 A fuse since 1998. And note: The mains voltage here is 230 Volt, so any short circuits are even more destructive at this double voltage.

The damaged copper tracks are fairly easy to repair with thin copper wires taken from a piece of multicore cable.

And a new triac is only few $$

Good luck and take care. Keep us posted

I noticed the new auger is 0.45 amps the old was 0.41 I wouldn’t think that could cause the problem.

Also all the blown fuses where 6amp fast.

Mt Bob

Minister of Fire

Ssyko

Minister of Fire

Your new auger draws .04a more than the old one and should not have that much diff as long as the max amp draw of the board does not exceed your Fuse. now are all the motors original to the stove? im thinking new auger is taking out the triac and the triac shorting is blowing the fuse. Bugs can you pull the auger and bench test it with outlet power and check the amps its drawing without the board in the loop?

Ssyko

Minister of Fire

Mt Bob

Minister of Fire

We have overloaded this poor man with much info.we appreciate all help,you are intelligent,yet appears you sometimes reply before reading the whole thread,which leads to illogical reply's and questions.Calm down,have a beer.If I may ask,why are you running 5 pellet stoves?I am not trying to be rude,just trying to cut down the same questions asked,within the same thread,as I and stove owners do appreciate your help.where did you buy this new auger?

Ssyko

Minister of Fire

2 in the house 1 in my shop 1 in my sons place and an extra. im not trying to overload Bugs. not trying to impress either. logical mechanical mind wants to find out WHY is all.

I appreciate all the help I’m getting from everybody, I will probably pull the stove out and work on it today or tomorrow needs to be cleaned and I’ll have better access to putting the inline fuses in. I’ll see if I can bench test the new auger and check amp draw.

I’m not overwhelmed yet, I love a challenge and intelligent communications or I’m a dumb a$$... either way keep it coming, appears this maybe helpful to others experiencing similar issues.

I’m not overwhelmed yet, I love a challenge and intelligent communications or I’m a dumb a$$... either way keep it coming, appears this maybe helpful to others experiencing similar issues.

Stovensen

Minister of Fire

This spade connector is at times touching the air intake the insulation separates them but could this be a draw.

Good observation, Bugs. The cables on your old auger motor had a better routing, that's for sure. I've inserted your own pic, so we can compare. But hey, the new end plate should have a rubber bumper included. Is it possible to rest the auger housing/gearbox on this bumper, so that the spade connectors are turned away from the bottom of stove. The auger motor will function in any angle, just as long as it has something to rest on, when it is working ( producing torgue )

Last edited:

Stovensen

Minister of Fire

All the wiring needs a close inspection, and from your latest post, I can see that you have already started on this.

Your pics from the garage/shop are quite sharp and detailed, and from here nothing appears damaged or torn on the wiring harness. But a very close scrutiny with a lamp and a magnifying glass is needed. Is the insultation on the wires damaged in any remote places?

Is there any humidity combined with dirt/salts on the terminal strip that could turn conductive between the terminals? Yes, dirt combined with humidity can certainly be conductive if the dirt is just a little bit salty!!

Since it is the auger triac thats keeps blowing, everything points in direction of the auger and its wiring, though.

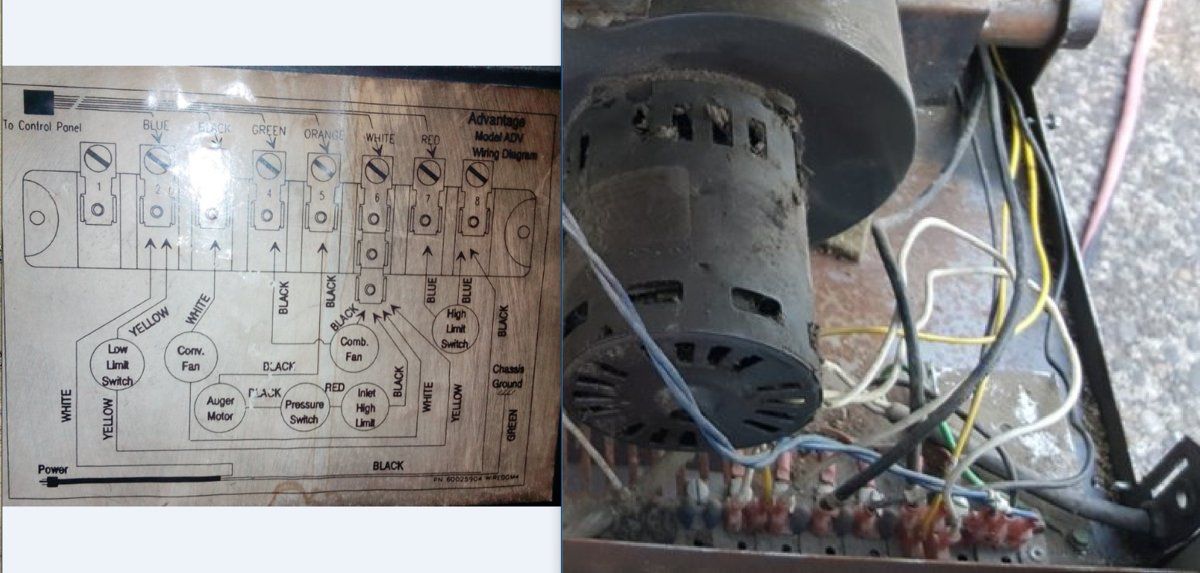

It should be possible to measure the current, the auger draws by taking a reading with an ampèremeter. You could insert the amp-meter several places: On the terminal strip by unplugging the spade connector on terminal point no.5 and insert the amp-meter in series with the disconnected points. See pictures of terminal strip below.

But access to the auger current measurement looks much better on the pressure switch. See picture from your shop.

The augercurrent flows through both pressure switch and inlet high limit switch and is the same through the entire chain, no matter where the amp-meter is inserted in the chain:

Access for augercurrent measurement is probably better on the pressure switch:

Now we are determined on both sides of the Atlantic to make this pellet stove work

Good luck and take care. Keep us posted

Your pics from the garage/shop are quite sharp and detailed, and from here nothing appears damaged or torn on the wiring harness. But a very close scrutiny with a lamp and a magnifying glass is needed. Is the insultation on the wires damaged in any remote places?

Is there any humidity combined with dirt/salts on the terminal strip that could turn conductive between the terminals? Yes, dirt combined with humidity can certainly be conductive if the dirt is just a little bit salty!!

Since it is the auger triac thats keeps blowing, everything points in direction of the auger and its wiring, though.

It should be possible to measure the current, the auger draws by taking a reading with an ampèremeter. You could insert the amp-meter several places: On the terminal strip by unplugging the spade connector on terminal point no.5 and insert the amp-meter in series with the disconnected points. See pictures of terminal strip below.

But access to the auger current measurement looks much better on the pressure switch. See picture from your shop.

The augercurrent flows through both pressure switch and inlet high limit switch and is the same through the entire chain, no matter where the amp-meter is inserted in the chain:

Access for augercurrent measurement is probably better on the pressure switch:

Now we are determined on both sides of the Atlantic to make this pellet stove work

Good luck and take care. Keep us posted

Last edited:

Similar threads

- Replies

- 28

- Views

- 461

- Replies

- 4

- Views

- 659

- Replies

- 3

- Views

- 1K

- Replies

- 8

- Views

- 900