So as mentioned above my 2 year old steel cat stopped working earlier this year. I tried to tell myself that the white smoke was just steam but 14%MC wood and the dripping tar on my chimney cap told me otherwise. So did the constant smoke, reduced burn times, stalling cat, and low output. My cat was not doing its job and the BK design depends on a functioning cat to create low emissions, long burns, adequate draft, and heat output. The cat is the heart of this stove. The wood makes smoke, the cat eats the smoke to heat your home.

This is my second cat. The first one was the OEM ceramic and died in a less dramatic way after almost three years, replaced under warranty by BK with no hassle. That cat was just starting to let blue smoke by so the ceramic lasted longer in the same stove before failing. I burn 8-9 months of the year. Well over 5000 hours per year in my climate which is wet, dark, drizzly, cloudy, and muddy for most of the months. This amount of use will rack up the hours on a cat and cat life is rated by the manufacturers in hours. So if you are comparing, be sure to realize that my year is probably double your year based on hours.

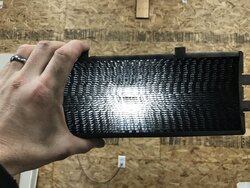

So with this dead steelcat I first cleaned it in place per the manual and found that even with clear cells it was dead. Second step, really a last ditch effort, I decided to remove the cat and try the vinegar bath to clean, dissolve, melt off any junk that had deposited onto the cat cells and covered up the catalyst. The theory is that the precious metals that create the catalytic reaction with smoke are still there but are just being blocked by the hard remnants of previously burned smoke. You can't blow these deposits off. They are hard, thin, and preventing the cat from working. The deposits can be dissolved by acid and vinegar is acetic acid. Several different stove makers, catalyst makers, catalyst resellers, and even BK at one time have described the exact process of the acid bath. Each of the sources describes the same method so I felt like there was an agreed upon process and that's what I did exactly.

What follows are the photos of the acid bath process. I spent about 20$ on materials and about 4 hours of precious time. It was fun and I can probably do it faster next time. A new cat can be delivered to your home for 186$ in two days so if you value your time highly then you might be wise to just swap a new one in instead of the acid bath. I hate wasting stuff and want to revive the dead cat if possible and also as a learning experience for me and you folks. One gallon of distilled vinegar (used almost all of it) and 4 gallons of distilled water.

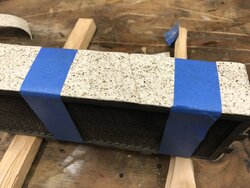

So I pulled the cat out with my fingers. Easy. The cat gasket is not reusable and fell out onto the firebox floor. I found a really wide 12" diameter, stainless steel, 5 quart pan in the kitchen with 3" tall sides to do the work. Make sure it fits. Once the cat is out of the stove you are kinda dead in the water. Make sure you have 36" of new cat gasket. That gasket is like 2$ per foot plus shipping. Note that I have a weird steel curtain behind my cat, supposedly this curtain is not present in all stoves. Looks to be just a baffle to prevent exhaust from shooting straight into the flue.

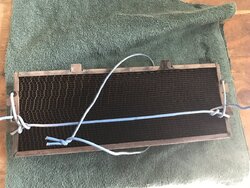

I fashioned a little handle out of some 14 gauge coated wire. You will use these handles a lot. I also installed a wire around the cat to keep it off of the bottom of the pot which will allow a flow of acid through the catalyst. If it just sits on the bottom then less acid will be able to flow through and remove deposits.

Getting long. To be continued.

This is my second cat. The first one was the OEM ceramic and died in a less dramatic way after almost three years, replaced under warranty by BK with no hassle. That cat was just starting to let blue smoke by so the ceramic lasted longer in the same stove before failing. I burn 8-9 months of the year. Well over 5000 hours per year in my climate which is wet, dark, drizzly, cloudy, and muddy for most of the months. This amount of use will rack up the hours on a cat and cat life is rated by the manufacturers in hours. So if you are comparing, be sure to realize that my year is probably double your year based on hours.

So with this dead steelcat I first cleaned it in place per the manual and found that even with clear cells it was dead. Second step, really a last ditch effort, I decided to remove the cat and try the vinegar bath to clean, dissolve, melt off any junk that had deposited onto the cat cells and covered up the catalyst. The theory is that the precious metals that create the catalytic reaction with smoke are still there but are just being blocked by the hard remnants of previously burned smoke. You can't blow these deposits off. They are hard, thin, and preventing the cat from working. The deposits can be dissolved by acid and vinegar is acetic acid. Several different stove makers, catalyst makers, catalyst resellers, and even BK at one time have described the exact process of the acid bath. Each of the sources describes the same method so I felt like there was an agreed upon process and that's what I did exactly.

What follows are the photos of the acid bath process. I spent about 20$ on materials and about 4 hours of precious time. It was fun and I can probably do it faster next time. A new cat can be delivered to your home for 186$ in two days so if you value your time highly then you might be wise to just swap a new one in instead of the acid bath. I hate wasting stuff and want to revive the dead cat if possible and also as a learning experience for me and you folks. One gallon of distilled vinegar (used almost all of it) and 4 gallons of distilled water.

So I pulled the cat out with my fingers. Easy. The cat gasket is not reusable and fell out onto the firebox floor. I found a really wide 12" diameter, stainless steel, 5 quart pan in the kitchen with 3" tall sides to do the work. Make sure it fits. Once the cat is out of the stove you are kinda dead in the water. Make sure you have 36" of new cat gasket. That gasket is like 2$ per foot plus shipping. Note that I have a weird steel curtain behind my cat, supposedly this curtain is not present in all stoves. Looks to be just a baffle to prevent exhaust from shooting straight into the flue.

I fashioned a little handle out of some 14 gauge coated wire. You will use these handles a lot. I also installed a wire around the cat to keep it off of the bottom of the pot which will allow a flow of acid through the catalyst. If it just sits on the bottom then less acid will be able to flow through and remove deposits.

Getting long. To be continued.

Last edited by a moderator: