Hi

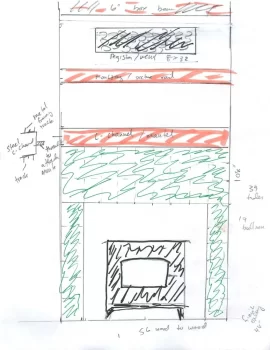

I am building an alcove where we removed a 1910 fireplace (new foundation and excavation) for a seismic upgrade. We are less than a mile from the Hayward Fault. The alcove is 57" wide by 31" deep and 9 feet to the ceiling. I have a Lopi Patriot but may upgrade to a larger and better stove at some point in the future and thus want to have convection walls on the side. I need one in the rear regardless, I believe. We will use double wall pipe (selkirk metalbestos) and I will reframe the front wall in steel and add a large grate at the top for air to escape. I want to line the alcove with ceramic tile which will also require backer board (durock). I plan on going up 7 or 8 feet with the tiled convection wall.

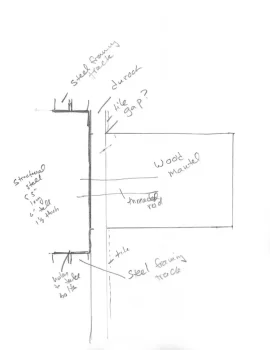

I have three sets of questions. First, I plan on attaching the outer layer of durock to steel framing and am wondering what I should use to close the seams to keep heated air from moving behind the outer wall and to wood framing (behind the steel framing)? I am thinking something like thin set but do not know if it is fireproof enough.

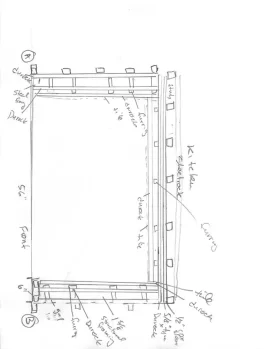

Second, I need to attach the 1" standoffs to the outer layer of durock. I am thinning of using 1" aluminum or 1 5/8 steel framing. I see problems with both. If I need to leave a 1" gap at the bottom (in other words, if the aluminum tubing cannot rest on the floor with the duck and tile starting an inch up), there will be a lot of weight pulling down and/or in on the tubing. Can the tubing rest on the floor or at least can I remove an inch from the outer face and have it rest on the floor? If one of these is possible, aside from attaching it with countersunk screws, can or should I use a mastic to improve its adhesion to the durock? The other option I see, and I believe it would do a better job of carrying the load, is to use 1 5/8" structural steel framing for the wall. I could have the framing run from the durock on the hearth to the ceiling so there would be plenty of gap above the tiles. The problem is the track (about an inch and a quarter high.) Can I attach a strip of durock and tile to the track and then have an inch or inch and a half air gap right above the track?

Third, I would like to have a wooden mantel at about 6' height. I am thinking that when I rebuild the front wall in steel, I could have a piece of 1.5 or 1.375" thick by 6" wide C channel with flanges on the ends that could be screwed to the wood framing (maybe with a piece of durock as a buffer) and some threaded posts above and below for attaching the tracks. I would then want stronger threaded posts coming out the front to attach the mantel piece. I am worried about heat transfer here though. Any recommendations? I will durock but not tile the interior of the front wall and on the exterior I plan on using plaster above (over eurock) and 6x6 ceramic tile up to the mantel.

Thanks

Rob

I am building an alcove where we removed a 1910 fireplace (new foundation and excavation) for a seismic upgrade. We are less than a mile from the Hayward Fault. The alcove is 57" wide by 31" deep and 9 feet to the ceiling. I have a Lopi Patriot but may upgrade to a larger and better stove at some point in the future and thus want to have convection walls on the side. I need one in the rear regardless, I believe. We will use double wall pipe (selkirk metalbestos) and I will reframe the front wall in steel and add a large grate at the top for air to escape. I want to line the alcove with ceramic tile which will also require backer board (durock). I plan on going up 7 or 8 feet with the tiled convection wall.

I have three sets of questions. First, I plan on attaching the outer layer of durock to steel framing and am wondering what I should use to close the seams to keep heated air from moving behind the outer wall and to wood framing (behind the steel framing)? I am thinking something like thin set but do not know if it is fireproof enough.

Second, I need to attach the 1" standoffs to the outer layer of durock. I am thinning of using 1" aluminum or 1 5/8 steel framing. I see problems with both. If I need to leave a 1" gap at the bottom (in other words, if the aluminum tubing cannot rest on the floor with the duck and tile starting an inch up), there will be a lot of weight pulling down and/or in on the tubing. Can the tubing rest on the floor or at least can I remove an inch from the outer face and have it rest on the floor? If one of these is possible, aside from attaching it with countersunk screws, can or should I use a mastic to improve its adhesion to the durock? The other option I see, and I believe it would do a better job of carrying the load, is to use 1 5/8" structural steel framing for the wall. I could have the framing run from the durock on the hearth to the ceiling so there would be plenty of gap above the tiles. The problem is the track (about an inch and a quarter high.) Can I attach a strip of durock and tile to the track and then have an inch or inch and a half air gap right above the track?

Third, I would like to have a wooden mantel at about 6' height. I am thinking that when I rebuild the front wall in steel, I could have a piece of 1.5 or 1.375" thick by 6" wide C channel with flanges on the ends that could be screwed to the wood framing (maybe with a piece of durock as a buffer) and some threaded posts above and below for attaching the tracks. I would then want stronger threaded posts coming out the front to attach the mantel piece. I am worried about heat transfer here though. Any recommendations? I will durock but not tile the interior of the front wall and on the exterior I plan on using plaster above (over eurock) and 6x6 ceramic tile up to the mantel.

Thanks

Rob