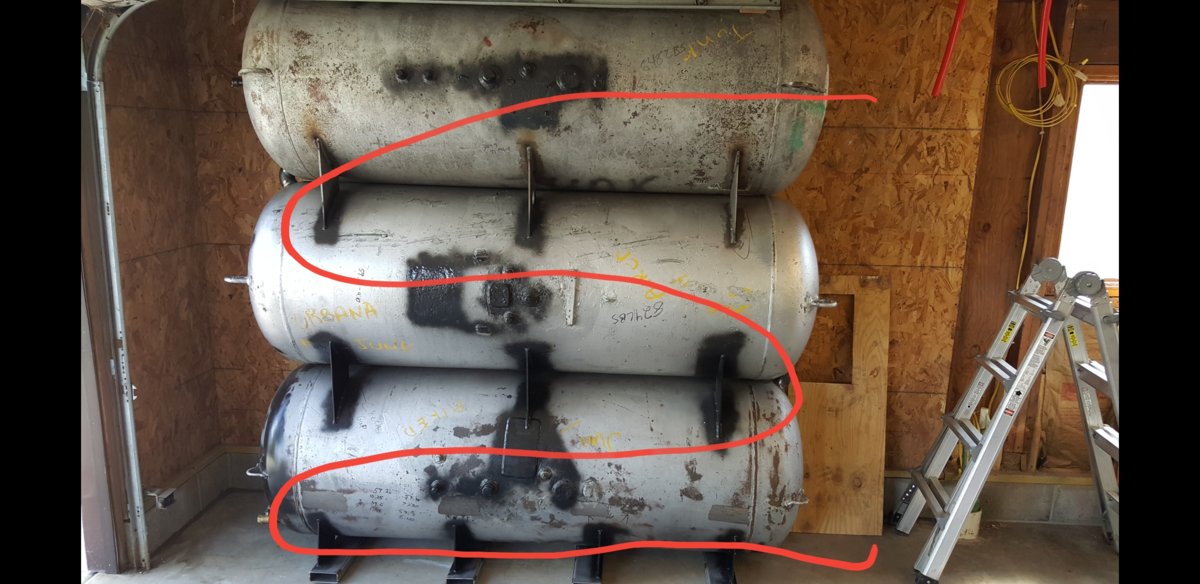

Here is how the flow runs through my tanks.

And here you can see my supply and return headers. My headers are 3" pipe. Each with 3) 1" connections.

And the water flows from tank to tank via a 2" 90° elbow that couldn't have fit better in its location.

I built the stack laying on its side on my garage floor then stood up the bottom and middle tank as 1 unit and set the top tank on top while in location. I had my father help with a skid loader for all that. It was fun considering my stack is 93" tall and my garage ceiling is 96". And yes I did later box in the stack and insulated everything.

And here you can see my supply and return headers. My headers are 3" pipe. Each with 3) 1" connections.

And the water flows from tank to tank via a 2" 90° elbow that couldn't have fit better in its location.

I built the stack laying on its side on my garage floor then stood up the bottom and middle tank as 1 unit and set the top tank on top while in location. I had my father help with a skid loader for all that. It was fun considering my stack is 93" tall and my garage ceiling is 96". And yes I did later box in the stack and insulated everything.