My replumbing project

- Thread starter warno

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

jwise87

Member

I was running the boiler circ on speed 3 when I was seeing the delta T of about 10°F. I turned it down to speed 2 because it was starting to cavatate. But the delta T didn't change any. I choked the valves at the boiler to try to get a higher delta but still nothing. I slowed the circ down to speed 1 and it barely changed anything.

On the storage side I wasn't actually running my circ but I was running my fill water from my garden hose through the FPHX. The water was going in at around 44° and coming out at almost 100°. But my garden hose had terrible pressure so the stupid slow flow rate is why the delta was so high on that side.

@Woodman1 my boiler is not pressurized but my storage is. And you're right I hate the idea of letting more heat go up the stack but I hate the idea of the boiler in idle mode even more.

I will do another fire with the storage side circ running and see if that changes anything. I'm not sure how I could but couldn't hurt to try it.

On the storage side I wasn't actually running my circ but I was running my fill water from my garden hose through the FPHX. The water was going in at around 44° and coming out at almost 100°. But my garden hose had terrible pressure so the stupid slow flow rate is why the delta was so high on that side.

@Woodman1 my boiler is not pressurized but my storage is. And you're right I hate the idea of letting more heat go up the stack but I hate the idea of the boiler in idle mode even more.

I will do another fire with the storage side circ running and see if that changes anything. I'm not sure how I could but couldn't hurt to try it.

jwise87

Member

maple1

Minister of Fire

You were heating the crap out of that water if it was going from 40 to 100, plus not dropping your boiler water temp. Maybe you just need more stuff to heat. Get a hot tub, or offer to heat your neighbors house too.

Yeah, it was flowing slower than 2 slugs fornicating in a puddle of molasses. Some quick math says my garden hose was flowing roughly 1.5 gpm. I've got my storage side circ running now.

It sounds like you just need more flow on the storage side to pull that boiler harder

The storage side circ is running now. I'll run out and get a quick temp reading in a little bit.

Sounds like you weren't flowing much through the storage side of the HX.

I was using my garden hose to fill my storage tanks. Apparently we have horrible water pressure at the spigot. I had it hooked up to the line that runs through the FPHX then returning into my tanks. I figured no point in putting 40 degree water in the tanks.

I just went to check temps and the boiler is running a DT of 12-15°F and the storage is picking up DT of about 20°F. The boiler isn't losing ground to the storage nor is it shooting temps up. The storage was reading about 95 and the boiler was about 107. It seems turning on the storage side circ has helped.The hoping this isn't a fluke deal and it keeps up this way.

I'm trying to wrap my head around why flowing more water through the storage side would help keep things in check. It seems if you're flowing near freezing water through the FPHX it should cool things down dramatically but i guess not?

I'm trying to wrap my head around why flowing more water through the storage side would help keep things in check. It seems if you're flowing near freezing water through the FPHX it should cool things down dramatically but i guess not?

maple1

Minister of Fire

It just wasnt flowing enough, I guess. What were your boiler temps yesterday when you were doing the 10dt thing?

It just wasnt flowing enough, I guess. What were your boiler temps yesterday when you were doing the 10dt thing?

Boiler temps were 160 and climbing with those deltas I had yesterday

maple1

Minister of Fire

I would have expected closer to that coming out of the HX with flow that low. But you did raise it quite a lot. Just wasnt enough of it.

1.5 x 500 x 60 = 45,000 btu

10 x 500 x 20 = 100,000 btu

So what you're saying is it's all in the math? Lol it's actually makes more sense seeing that.

Where's the 500 come from?

maple1

Minister of Fire

With each fire I'm a little more optimistic. I started a small fire after work today and got the storage to 140° and the boiler shut down at 150°. I started another fire and went for poring the coals to it. The boiler at peak burn was at 180 and the storage was climbing with a delta of 25° through the HX. The boilers delta was about 20°. I turned the boiler pump up to speed 2 which should be running about 8 GPM and the storage pump is on speed 3 which should be around 22 gpm.

I haven't been staring at the boiler the whole burn but the times I've checked it was not idling. So fingers crossed.

I haven't been staring at the boiler the whole burn but the times I've checked it was not idling. So fingers crossed.

maple1

Minister of Fire

Ummm, dt of 25 at 22 gpm is over 200,000 btu/hr. That would be pretty huge.

I thought about that after I wrote it. I switched my storage pump to speed 3 after I took that temp reading. It was on speed 2 when I took that reading. I actually don't know what the delta would be at right now on speed 3.

maple1

Minister of Fire

Likely the fuzziest part is gpm estimation. Your boiler side there works out to almost 80,000 btu/hr, which is respectable. Did you ever have a btu/hr figure in mind for what you'd like out of your boiler?

Likely the fuzziest part is gpm estimation. Your boiler side there works out to almost 80,000 btu/hr, which is respectable. Did you ever have a btu/hr figure in mind for what you'd like out of your boiler?

No I never did actually. I built it to almost the same specs as a manufactured boiler. That boiler claims to be about 225,000 btu. I'll re run my numbers on my head loss and try to get a closer estimation on gpm.

BoiledOver

Minister of Fire

Glad to hear things are looking up for you. Wondering about your changes since last winter and have a few questions. Did you dissect the old circulator that was experiencing cavitation issues? Any comments on the impeller? Are you now using the same model circulator on both sides of the flat plate?

Can't imagine a cavitation issue with your new boiler layout. You are drawing from the flat plate with that circ sitting low in the loop, yes?

Can't imagine a cavitation issue with your new boiler layout. You are drawing from the flat plate with that circ sitting low in the loop, yes?

Glad to hear things are looking up for you. Wondering about your changes since last winter and have a few questions. Did you dissect the old circulator that was experiencing cavitation issues? Any comments on the impeller? Are you now using the same model circulator on both sides of the flat plate?

Can't imagine a cavitation issue with your new boiler layout. You are drawing from the flat plate with that circ sitting low in the loop, yes?

Yes, I did break down the circ that was cavitating. I couldn't see anything wrong with the impeller. That circ is on my storage side now.

My boiler circ is still running on the supply side pumping away from the boiler into the FPHX. I was hoping it would not cavitate anymore because it's so much lower than last year in the loop.

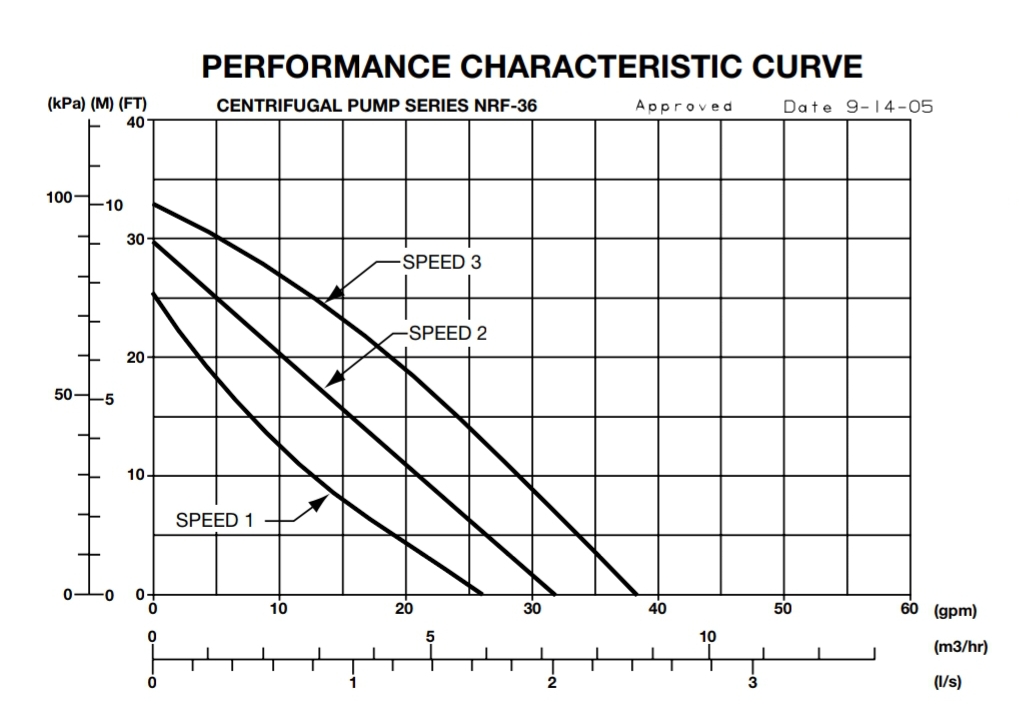

I'm using the same circulators as last year but I've switched their sides. My bell and gossett NRF-36 is running the storage side due to the higher head of the 2 loops. And my grundfos 15-58 is running my boiler side.

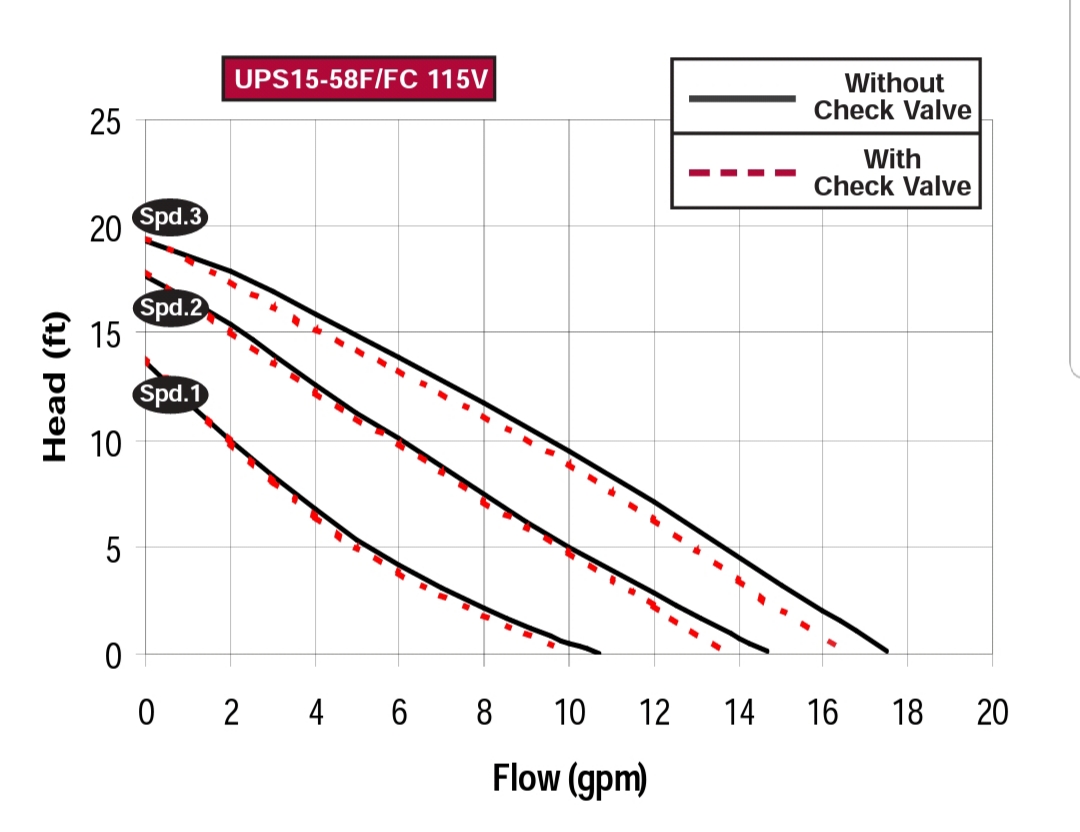

So I've come up with roughly the same numbers for head loss. The boiler side is roughly 5 ft of head and the storage side, rounded up, is 15 ft of head. Boiler side circ is a grundfos 15-58 and the storage circ is a bell and gossett NRF-36.

Boiler side (5ft of head) set to speed 2

Storage (15ft of head) set to speed 3

When I was reading a dt of 25° on the storage side the circ was on speed 2. And the boiler side circ was on speed 2 with the dt of 20°.

Boiler side (5ft of head) set to speed 2

Storage (15ft of head) set to speed 3

When I was reading a dt of 25° on the storage side the circ was on speed 2. And the boiler side circ was on speed 2 with the dt of 20°.

It turns out an air locked circ makes some funny noises. I filled my garage heating loop this afternoon to start heating the garage since everything else seemed fine. Again with my terrible garden hose water pressure. I thought the loop was purged of air. Apparently not! A big air bubble must have made its way out of the loop and into the storage tank header. The FPHX circ sucked it up and couldn't digest it.

I went out, about 1 hour after starting the fire, to a idling boiler and some very strange delta readings. Both underground lines in the boiler shed read around 178 and both lines in the garage read around 108. It took me a good 15 minutes running back and forth trying different things before I figured out the water wasn't moving. I opened the bleeder port going to the underground lines and nothing but air came out. And the pump quieted right down and started working properly again.

On a good side note though. The boiler shed circ was not cavitating, even with 210° water running through it. Not sure why it did it the other day at 170 but I'll take it.

I went out, about 1 hour after starting the fire, to a idling boiler and some very strange delta readings. Both underground lines in the boiler shed read around 178 and both lines in the garage read around 108. It took me a good 15 minutes running back and forth trying different things before I figured out the water wasn't moving. I opened the bleeder port going to the underground lines and nothing but air came out. And the pump quieted right down and started working properly again.

On a good side note though. The boiler shed circ was not cavitating, even with 210° water running through it. Not sure why it did it the other day at 170 but I'll take it.

Similar threads

- Replies

- 8

- Views

- 539

- Replies

- 10

- Views

- 2K

- Replies

- 22

- Views

- 1K

- Replies

- 17

- Views

- 484