Informational Purposes Only! Don't try this at home!

I saw the pricing of new control boards (~$200.00) and thought I could make one for a whole lot less. Actually it cost less than $30.00.

I only built this for emergency backup purposes only.

No auto start igniter, but that would be another simple circuit if I really needed it. I can use a propane torch to start her up.

Prices are approximate.

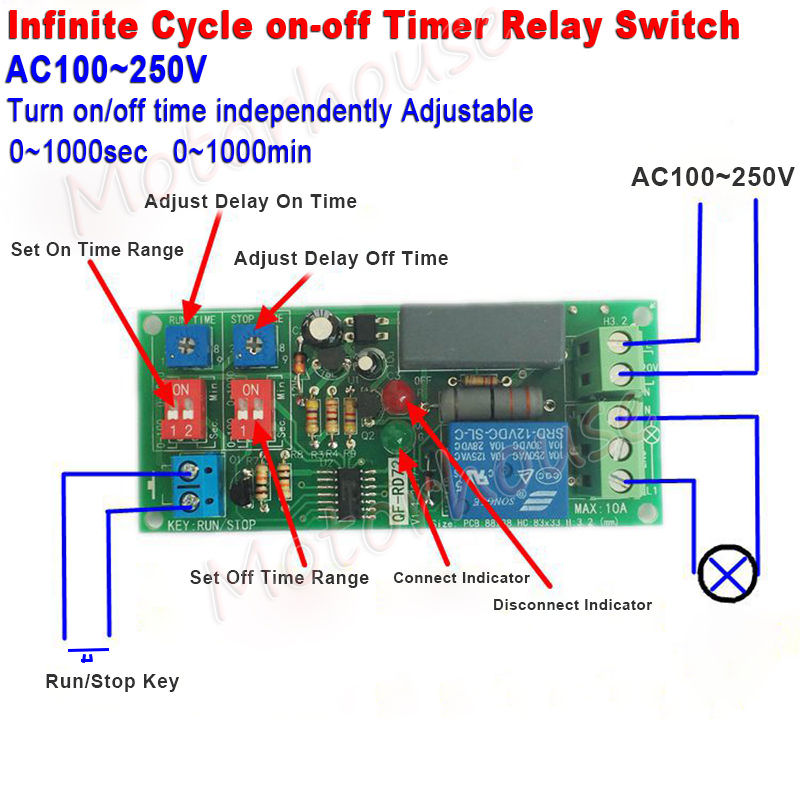

I found a motor control board (On/Off timer relay). $5.00

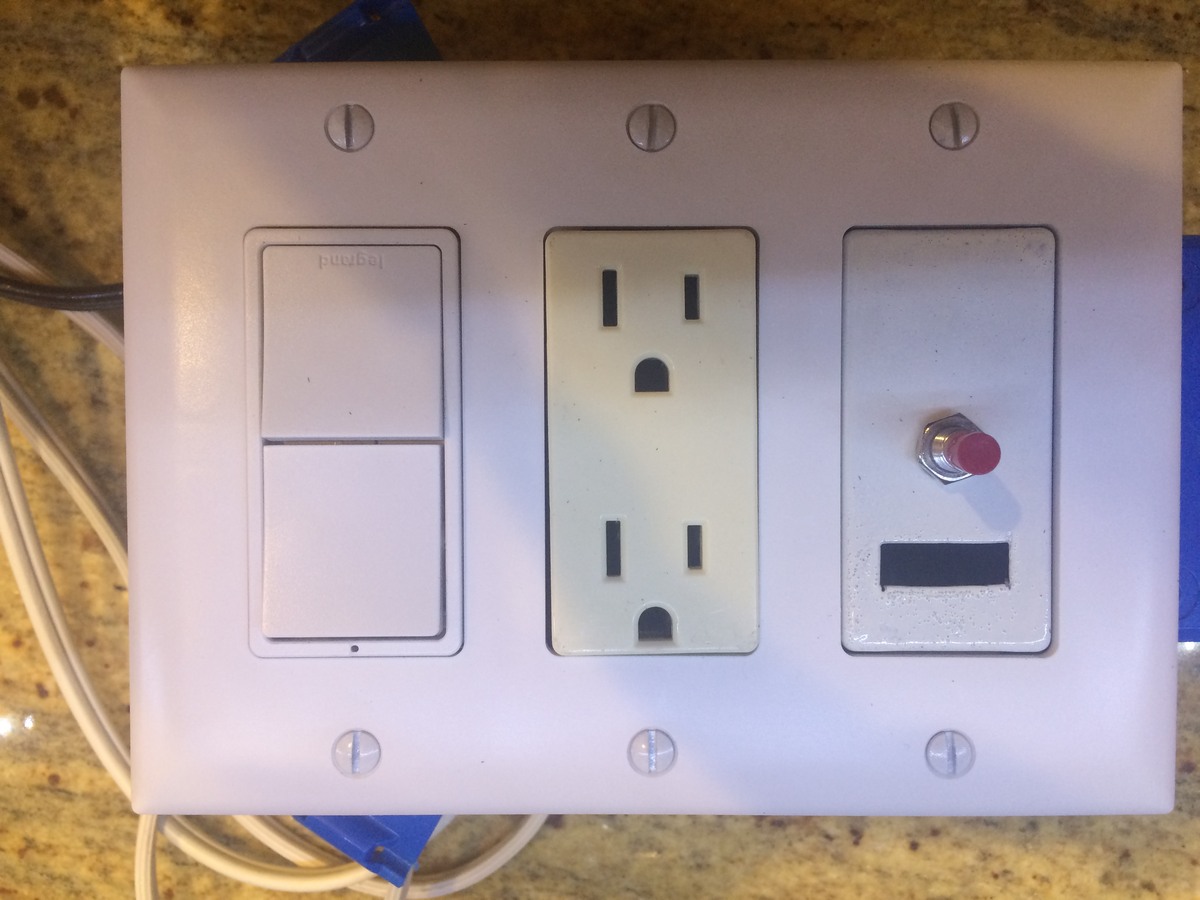

3-gang outlet box $3.00

Outlet $3.00

Double Switch $8.00

Outlet blank filler $4.00

Outlet cover $3.00

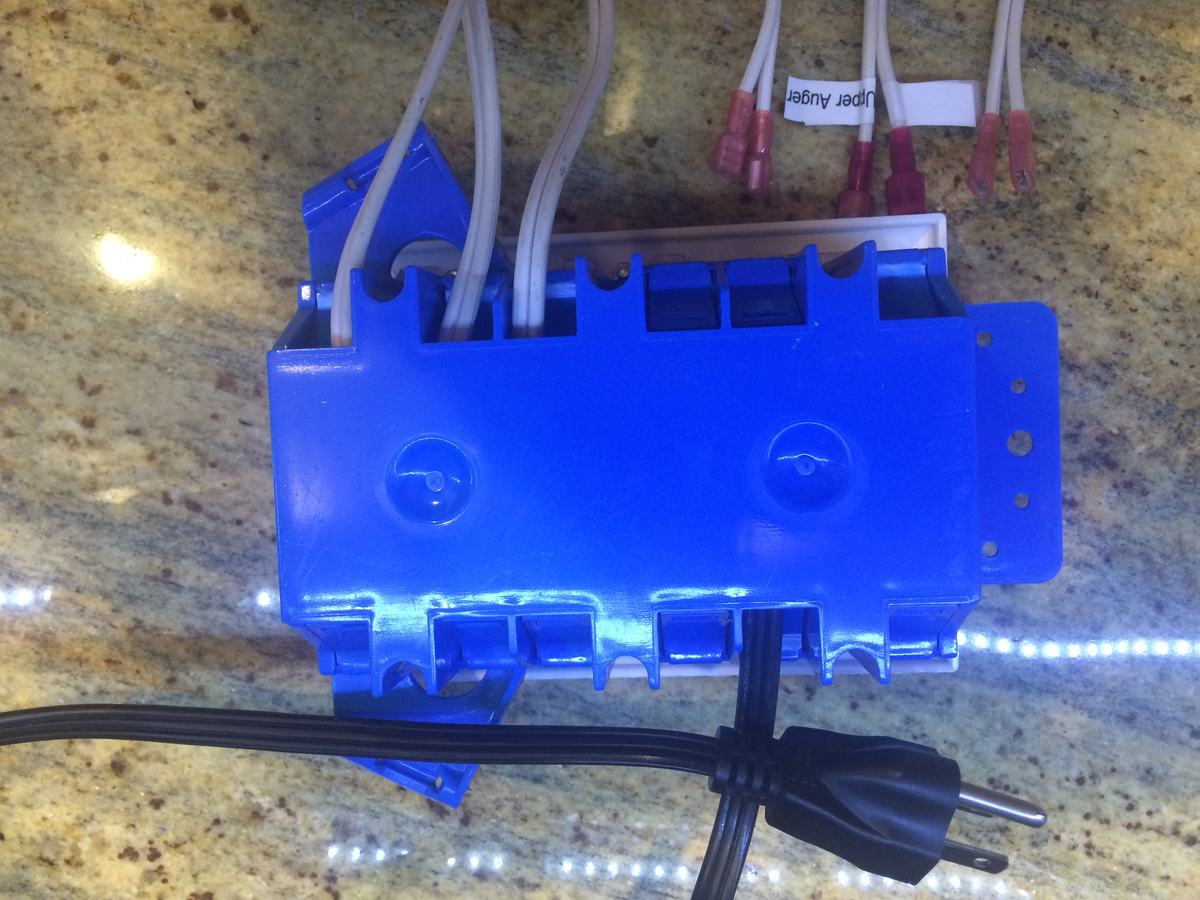

Miscellaneous wires from the garage $Free

I saw the pricing of new control boards (~$200.00) and thought I could make one for a whole lot less. Actually it cost less than $30.00.

I only built this for emergency backup purposes only.

No auto start igniter, but that would be another simple circuit if I really needed it. I can use a propane torch to start her up.

Prices are approximate.

I found a motor control board (On/Off timer relay). $5.00

3-gang outlet box $3.00

Outlet $3.00

Double Switch $8.00

Outlet blank filler $4.00

Outlet cover $3.00

Miscellaneous wires from the garage $Free

Last edited: