I am looking for suggestions on hooking up my central boiler to a second small house on my property.currently it is only heating my 24x40 garage,and is doing a awesome job.I had to pay a contractor to switch over my heating in my garage,and he charged a arm and leg and all my copper pipes are crooked.

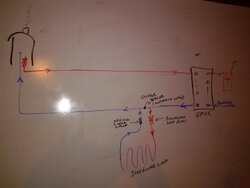

I do not want to pay this contractor to do this small house if i do not have to.currently i am heating this small house with 1 30,000btu ventless heater.I do not have any kind of furnace inside.I know i need to install 2 brazed plate heat exchangers.1 for my domestic hot water,and 1 for my other heat.I was going to install hot water baseboard to heat the house with,but not sure if i need like a propane boiler inside to go through first,or can i just hook up a brazed plate heat exchanger,and a circulating pump that will kick on to heat the house when the new thermostat would call for heat.

If anyone out there could help me with laying something out for this small house,I would greatly appreciate it.

I will have a 2nd house to hook up to this boiler after i get this small house hooked up.my boiler has 3 connections for 3 pumps,and i want to eventually heat all 3 buildings.

Thanks in advance for any help.any further questions about anything please ask.

I do not want to pay this contractor to do this small house if i do not have to.currently i am heating this small house with 1 30,000btu ventless heater.I do not have any kind of furnace inside.I know i need to install 2 brazed plate heat exchangers.1 for my domestic hot water,and 1 for my other heat.I was going to install hot water baseboard to heat the house with,but not sure if i need like a propane boiler inside to go through first,or can i just hook up a brazed plate heat exchanger,and a circulating pump that will kick on to heat the house when the new thermostat would call for heat.

If anyone out there could help me with laying something out for this small house,I would greatly appreciate it.

I will have a 2nd house to hook up to this boiler after i get this small house hooked up.my boiler has 3 connections for 3 pumps,and i want to eventually heat all 3 buildings.

Thanks in advance for any help.any further questions about anything please ask.