DuraBlack help needed

- Thread starter Mojappa

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

brenndatomu

Minister of Fire

Cool lookin cat!

Yeah this looks like a bit of a challenge...can you raise the furnace up 4-5" more? Do without the elbows then...not ideal, but if you have a good chimney system otherwise, it will work fine...you need 1/4" rise per foot of run as a bare minimum. I currently have a pipe that runs kinda like that...3" rise in 4'...works well...goes into a lined 25' chimney though too...

Yeah this looks like a bit of a challenge...can you raise the furnace up 4-5" more? Do without the elbows then...not ideal, but if you have a good chimney system otherwise, it will work fine...you need 1/4" rise per foot of run as a bare minimum. I currently have a pipe that runs kinda like that...3" rise in 4'...works well...goes into a lined 25' chimney though too...

She’s our newest addition. Lost my best buddy in November (one in my avatar pic) and had to get something to fill the void, so I got another bengal.

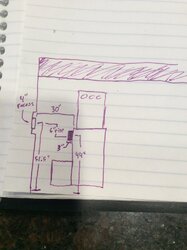

I’d have to raise it 6” to make it even with the thimble, but then I’d have no rise. if it isn’t even with the flue wouldn’t there need to be elbow pieces? Just curious, why would I wanna get rid of the rise I do have? Wouldn’t that make it technically a horizontal run from the from of the furnace where the flue pipe starts all the way to the back of the thimble, that would make for like a 5’ horizontal run.

Thought about starting off with just two 45’s and a straight piece (no tee) so I can get it running and see if the barometric damper is actually needed. Knowing my luck though, my draft will be wonky and I’ll need all sorts of extra stuff to make this work.

Attached a pic of the chimney (On the left), not sure how tall it is but it goes down to the ground. I know it doesn’t meet the 10’ to the roof clearances that I’ve read about. Hoping I don’t have to extend it, this install is getting more and more involved as I go.

I’d have to raise it 6” to make it even with the thimble, but then I’d have no rise. if it isn’t even with the flue wouldn’t there need to be elbow pieces? Just curious, why would I wanna get rid of the rise I do have? Wouldn’t that make it technically a horizontal run from the from of the furnace where the flue pipe starts all the way to the back of the thimble, that would make for like a 5’ horizontal run.

Thought about starting off with just two 45’s and a straight piece (no tee) so I can get it running and see if the barometric damper is actually needed. Knowing my luck though, my draft will be wonky and I’ll need all sorts of extra stuff to make this work.

Attached a pic of the chimney (On the left), not sure how tall it is but it goes down to the ground. I know it doesn’t meet the 10’ to the roof clearances that I’ve read about. Hoping I don’t have to extend it, this install is getting more and more involved as I go.

Attachments

Last edited:

Another thought, is there any reason I couldn’t push it closer to the wall? There are no combustibles nearby aside from the floor joists which have 6” of clearance from the plenum. Eventually I plan to install a return duct to the back, does that take any more space than the existing “filter box” on the back? What’s the closest I’d want that box to be to the wall for airflow purposes?

brenndatomu

Minister of Fire

That's why I said raise it 4-5"...so you still have a little rise...it could be a challenge getting the pipe together depending on how tight everything fits together. (due to the slight angle) But with that short of a chimney it might be a bad idea to ty that.

This is starting to look like a good place to put some single wall adjustable elbows instead of rigid 45's. I'd use stainless though...we have a little amish metal shop that makes stainless chimney parts near here...pretty reasonable too.

This is starting to look like a good place to put some single wall adjustable elbows instead of rigid 45's. I'd use stainless though...we have a little amish metal shop that makes stainless chimney parts near here...pretty reasonable too.

brenndatomu

Minister of Fire

Yeah I sure wouldn't run any ductwork until you sort the stove pipe out...may need to scoot it closer or further away from the chimney to get things to work out

brenndatomu

Minister of Fire

I didn't realize that the Durablack elbows were adjustable...looks like they are now...didn't used to be I don't believe...

Yeah, once I saw that they’re adjustable now it seemed reasonable to use them. If they were rigid 45’s it would be a nightmare for sure. So that should prevent the “need” to raise the stove, correct?

I was also a little surprised that the barometric damper has a gap around the outside of the flap, not sure why but I figured that would be pretty much closed unless the damper has to open. I assume it’s supposed to be that way, just seemed odd to me and my limited knowledge of these things.

Still not quite sure how the telescoping function of the durablack works or which pieces I’d need, if they come short enough that is.

Anybody out there know if I’ll need any adapters to attach the flue pipe to the stove or thimble?

I was also a little surprised that the barometric damper has a gap around the outside of the flap, not sure why but I figured that would be pretty much closed unless the damper has to open. I assume it’s supposed to be that way, just seemed odd to me and my limited knowledge of these things.

Still not quite sure how the telescoping function of the durablack works or which pieces I’d need, if they come short enough that is.

Anybody out there know if I’ll need any adapters to attach the flue pipe to the stove or thimble?

brenndatomu

Minister of Fire

Yeah.So that should prevent the “need” to raise the stove, correct?

You'll find that the baro is open (at least a little) most of the time when you are running anyways, so that little gap doesn't amount to much.

As far as the telescoping...what ever the full length is...fully collapsed will be about 50%...slightly more than.

I'd order the shortest telescoping piece they have...then figure up the installed length of (2) elbows, (1) tee, (1) telescoping pipe, and then (1) short rigid pipe section, length as calculated. The good thing is you can move the furnace a little if you need to.

Looking at their catalog...its kinda confusing...I think I would call them...see if they can help you figure out what you need.

Hard to tell but looks like the double skirted one could work. If I u n it correctly it seems like it slips over the pipe from the back of the furnace but there’s a male end inside that also goes inside the stovepipe, otherwise creosote could flow out of the joint. The other adapter they sell seems to be for top exit stoves. Ultimately I guess I’ll have to invest some time talking to them, just hoped for an easier answer to the adapter thing. Thanks for the help so far, it’s hard to get legit advice around my area due to too many old timers stuck in the “you can’t burn pine” mentality. Seems most people know just enough to cobble something together and call it good, even more so when it comes to the ducting aspect of this.

brenndatomu

Minister of Fire

Yeah those guys are everywhere it seems...heck, even HVAC shops can't/don't install wood furnaces right half the time.it’s hard to get legit advice around my area due to too many old timers stuck in the “you can’t burn pine” mentality. Seems most people know just enough to cobble something together and call it good, even more so when it comes to the ducting aspect of this.

maple1

Minister of Fire

Turning it would put the door at a weird spot either way I spun it and the distance from the bottom of the steps would go down too, especially if I pointed the return box towards the steps. Also I don’t think turning it would make the stovepipe install any simpler and could just add another turn that reduces my draft.Would it help to, and can you, turn the furnace 90°?

maple1

Minister of Fire

IMO I think it might make pipe install easier. But whether it could be turned or not from operational aspect is another matter.

This pic shows the space it’s in fairly well. It’s almost 6’ from the wall to the right of it and about 5’ from the bottom of the steps. Turning it 90°CW would put the door about a foot closer to the steps.

The initial plan was to tap into the end of that trunk line and put a damper at the air handler plenum, but the trunk line isn’t rated for solid fuel, so now I’m gonna have a boatload of ducting running along the basement ceiling. Guess it’s good that I wasn’t planning on fully finishing the basement, function over form at this point

The initial plan was to tap into the end of that trunk line and put a damper at the air handler plenum, but the trunk line isn’t rated for solid fuel, so now I’m gonna have a boatload of ducting running along the basement ceiling. Guess it’s good that I wasn’t planning on fully finishing the basement, function over form at this point

brenndatomu

Minister of Fire

I think I would try to not use the appliance adapter...might need one on the chimney end though...hard to tell what it is gonna take to get things hooked up properly there. (why is there no liner tee snout sticking out into the room?) (is there enough sticking out to get 3 screws into it once assembled? Really need a proper mechanical connection...the first time you have a large "backfire" you'll be glad you did)

I think I'd just put a elbow into the back of the furnace, use a section of telescoping pipe up to the chimney (hopefully the other elbow will just slip right over the liner snout) ...so with the telescoping pipe extended, it is just singlewall pipe over most of its length...use the pipe adapter that comes with the baro (assuming you got the Fields baro) instead of a tee to install it on the pipe.

Bam, done.

Oh, I dunno the price difference, but consider ordering the stainless pipe...this is from experience, steel stove pipe only lasts a couple seasons on wood furnaces in the basement. Stainless is "buy once, cry once"

If you are going steel, might as well use the cheap stuff from the hardware/big box store...might not be a bad idea for the first round here anyways...until you get this figured out how you wanna configure things.

I think I'd just put a elbow into the back of the furnace, use a section of telescoping pipe up to the chimney (hopefully the other elbow will just slip right over the liner snout) ...so with the telescoping pipe extended, it is just singlewall pipe over most of its length...use the pipe adapter that comes with the baro (assuming you got the Fields baro) instead of a tee to install it on the pipe.

Bam, done.

Oh, I dunno the price difference, but consider ordering the stainless pipe...this is from experience, steel stove pipe only lasts a couple seasons on wood furnaces in the basement. Stainless is "buy once, cry once"

If you are going steel, might as well use the cheap stuff from the hardware/big box store...might not be a bad idea for the first round here anyways...until you get this figured out how you wanna configure things.

Last edited:

Had the chimney lined in Jan of 2016, but it seems maybe not as quality of a job as should have been.... the tee snout is the existing one before the chimney was lined. I assume it’s not done well from the sound of it, which is reassuring. Lol

I reckon I’ll get the 45’s and such and see where that gets me and go from there. Good thing about most of the durablack stuff is I can have it shipped to store so won’t have to worry about shipping costs.

Also, the Fields did come with the adapter, was just hoping to avoid needing to cut the pipe to use it. No biggie, if I can’t accomplish it with the tools I have my brother should be able to.

I reckon I’ll get the 45’s and such and see where that gets me and go from there. Good thing about most of the durablack stuff is I can have it shipped to store so won’t have to worry about shipping costs.

Also, the Fields did come with the adapter, was just hoping to avoid needing to cut the pipe to use it. No biggie, if I can’t accomplish it with the tools I have my brother should be able to.

Similar threads

- Replies

- 36

- Views

- 3K

- Replies

- 3

- Views

- 2K

- Replies

- 0

- Views

- 493

- Replies

- 0

- Views

- 588