Thanks to the great information provided here and on other firewood forums, I made an attempt at my own solar kilns based off @Woodsplitter67's excellent, @Poindexter-approved design. I will be running at least one into the winter.

Background

Last October I moved from my home in the Monadnock region of NH to north of Mount Kearsarge onto an 18 acre piece of land with about 16 acres very heavily wooded. Mostly 90' pine trees with a few hardwoods here and there. I left my 9 cords of hardwood cut and stacked with my old home as part of the sale, so I am starting fresh.

Solar Kilns

I have access to free pallets so I based my design off using those pallets and trying to adhere as closely as possible to @Woodsplitter67's design.

Each kiln holds 2.20 cords of wood, with 1.10 cords in each row.

I completed and fully wrapped my first kiln on August 7th. I completed and fully wrapped my second kiln on September 6th. The first kiln is behind the newer kiln. If my math is correct, I spaced the kilns far enough apart that the shadow of the second kiln shouldn't land on the first kiln even in winter.

State of Wood

My wood is not ideal. I hope to have a better baseline next year, but this year I am just trying to get everything in shape to survive the coming winter and have some decent wood to burn. All of my splits are 16" splits. Thickness varies.

In my first kiln I have half hardwood (mostly red oak and birch, a little beech) and half softwood (eastern white pine, I believe).

Most of my red oak is from a tree I felled fresh and stacked it on the kiln for only a couple weeks before wrapping it. The birch trees are all freshly felled, as is the beech. Some of the red oak is from a huge dead tree out back that I hauled down the mountain. The upper half of the tree hadn't started to go punky yet so I bucked and split that.

The softwood in the first kiln is all from five huge pine trees that fell in a terrible storm last November that took out a huge number of trees in my town. I bucked and split that wood this summer.

The second kiln is almost exclusively softwood that I felled and immediately stacked. It has been split and stacked from 1 month down to only days (as I filled it up before wrapping). I was a little short after the last pine tree so I finished it out with a handful of small birches that were damaged.

None of this wood was split and stacked over a month before cover it in the kiln, and some of it was less than that. Most of the wood is from freshly felled living trees and was very high MC--my moisture meter maxes out at 40% MC and all of this wood showed 39-40% when I first split and stacked it, but I did not re-test the wood (some of which was sitting there for a month or so) before wrapping it in plastic.

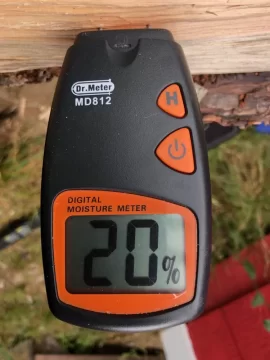

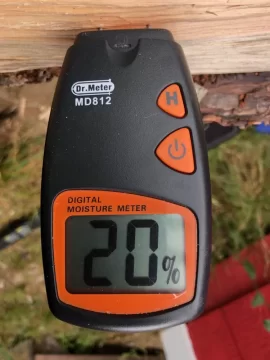

I pulled some splits out of my first kiln from the top row through the gable vents today. The pine looks like it is pretty much ready to burn, splits ranged from 20% to 25% MC.

Pine

The red oak is interesting. The very center is still 38% MC, but it dropped to 24% MC only a couple inches over, and to 19% about 2" in from the end of the split (all tested on the fresh face of the cut). So it's definitely drying out but the very center is still showing high MC. This is after only about 30 days in the kiln.

Red Oak - Center

Red Oak - 2" from End

Update:

A note on weather: My part of central NH enjoyed an especially cloudy and rainy Fall this year. We had precious few days of full sun; even the sunny days tended to be partly cloudy. I believe this slowed down kiln performance.

First Kiln 90 Day Performance

At 90 days, the red oak was still reading in the mid-20s when I removed and split several pieces to test MC. The birch, however, all tested in the low teens.

Red Oak

Birch

First Kiln 110 Day Performance and Second Kiln 80 Day Performance: Finished!

I am very happy to report that after 110 days in the kiln, even with a terribly cloudy season, both the freshly felled red oak and the storm-felled red oak are below 20% MC and ready to burn.

The red oak (first kiln) averaged 18.8% MC, but no test exceeded 20% MC.

The pine (second, later kiln) was all below 20% MC.

Red Oak (note: I took this split inside and warmed it up. This meter seems to read accurately in cold weather, as it actually tested lower (18.5% MC) after warming to 70dF)

Pine (second kiln, 80 days)

Snow Performance

We finally had a decent snowstorm, dropped 3.5 to 4 inches the first night and about as much the second. The following photo was taken the morning after the first snow fall.

I am happy to report that my theory proved true--the steep pitch of my kilns combined with the rope corners on each side simply dropped all of the snow off the kilns. As you can see from the undisturbed snow in the image below, I took this shot before I walked down the hill to the kilns. They dropped the snow on their own.

Note: all MC readings taken by performing a fresh split down the middle of a piece of firewood and taking the reading in the center of the fresh split, unless otherwise stated.

Background

Last October I moved from my home in the Monadnock region of NH to north of Mount Kearsarge onto an 18 acre piece of land with about 16 acres very heavily wooded. Mostly 90' pine trees with a few hardwoods here and there. I left my 9 cords of hardwood cut and stacked with my old home as part of the sale, so I am starting fresh.

Solar Kilns

I have access to free pallets so I based my design off using those pallets and trying to adhere as closely as possible to @Woodsplitter67's design.

Each kiln holds 2.20 cords of wood, with 1.10 cords in each row.

I completed and fully wrapped my first kiln on August 7th. I completed and fully wrapped my second kiln on September 6th. The first kiln is behind the newer kiln. If my math is correct, I spaced the kilns far enough apart that the shadow of the second kiln shouldn't land on the first kiln even in winter.

State of Wood

My wood is not ideal. I hope to have a better baseline next year, but this year I am just trying to get everything in shape to survive the coming winter and have some decent wood to burn. All of my splits are 16" splits. Thickness varies.

First Kiln

In my first kiln I have half hardwood (mostly red oak and birch, a little beech) and half softwood (eastern white pine, I believe).

Most of my red oak is from a tree I felled fresh and stacked it on the kiln for only a couple weeks before wrapping it. The birch trees are all freshly felled, as is the beech. Some of the red oak is from a huge dead tree out back that I hauled down the mountain. The upper half of the tree hadn't started to go punky yet so I bucked and split that.

The softwood in the first kiln is all from five huge pine trees that fell in a terrible storm last November that took out a huge number of trees in my town. I bucked and split that wood this summer.

Second Kiln

The second kiln is almost exclusively softwood that I felled and immediately stacked. It has been split and stacked from 1 month down to only days (as I filled it up before wrapping). I was a little short after the last pine tree so I finished it out with a handful of small birches that were damaged.

None of this wood was split and stacked over a month before cover it in the kiln, and some of it was less than that. Most of the wood is from freshly felled living trees and was very high MC--my moisture meter maxes out at 40% MC and all of this wood showed 39-40% when I first split and stacked it, but I did not re-test the wood (some of which was sitting there for a month or so) before wrapping it in plastic.

First Kiln 30 Day Performance

I pulled some splits out of my first kiln from the top row through the gable vents today. The pine looks like it is pretty much ready to burn, splits ranged from 20% to 25% MC.

Pine

The red oak is interesting. The very center is still 38% MC, but it dropped to 24% MC only a couple inches over, and to 19% about 2" in from the end of the split (all tested on the fresh face of the cut). So it's definitely drying out but the very center is still showing high MC. This is after only about 30 days in the kiln.

Red Oak - Center

Red Oak - 2" from End

Update:

A note on weather: My part of central NH enjoyed an especially cloudy and rainy Fall this year. We had precious few days of full sun; even the sunny days tended to be partly cloudy. I believe this slowed down kiln performance.

First Kiln 90 Day Performance

At 90 days, the red oak was still reading in the mid-20s when I removed and split several pieces to test MC. The birch, however, all tested in the low teens.

Red Oak

Birch

First Kiln 110 Day Performance and Second Kiln 80 Day Performance: Finished!

I am very happy to report that after 110 days in the kiln, even with a terribly cloudy season, both the freshly felled red oak and the storm-felled red oak are below 20% MC and ready to burn.

The red oak (first kiln) averaged 18.8% MC, but no test exceeded 20% MC.

The pine (second, later kiln) was all below 20% MC.

Red Oak (note: I took this split inside and warmed it up. This meter seems to read accurately in cold weather, as it actually tested lower (18.5% MC) after warming to 70dF)

Pine (second kiln, 80 days)

Snow Performance

We finally had a decent snowstorm, dropped 3.5 to 4 inches the first night and about as much the second. The following photo was taken the morning after the first snow fall.

I am happy to report that my theory proved true--the steep pitch of my kilns combined with the rope corners on each side simply dropped all of the snow off the kilns. As you can see from the undisturbed snow in the image below, I took this shot before I walked down the hill to the kilns. They dropped the snow on their own.

Note: all MC readings taken by performing a fresh split down the middle of a piece of firewood and taking the reading in the center of the fresh split, unless otherwise stated.

Last edited:

[emoji23][emoji23][emoji23]

[emoji23][emoji23][emoji23]