It looks like your model doesn’t have the c-cast panel. It's not listed in my owner's manual, but it's on Drolet's site for parts:What is a c-cast panel? I never heard of that term. My stove appears to just have the 5/16" stovetop....but one of the diagrams in the manual shows a dark line attached to the underside of the stovetop. That could be it. I'll have to look closer when the tubes and baffle board can be removed.

After I got this stove, I started to split my wood into larger pieces. I have oak, ash and hickory. That won't be seasoned for some time yet. Next years wood is already split....into the smaller pieces. I am going to try to kiln dry some of the larger splits in an attempt to have them ready for next year.

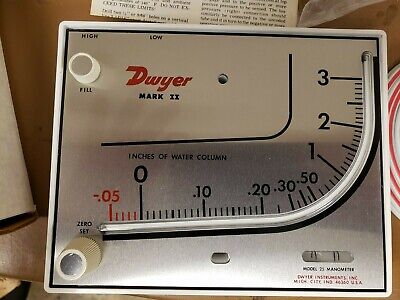

I believe that I have good draft. I have an OAK. It is a 5" diameter tube that SBI calls for in their specs. I can feel (and hear) the air entering the end of the tube. My primary air control is very sensitive. Small increments effect the flame in the firebox. I can see the movement of the flames when making adjustments to the primary air control --- The air rushing in and pushing the flames around. That makes me believe that I have good draft. Plus I have tried every combination of chimney height that I can.

If I want, I can create a massive inferno in the firebox. But the heat seems to go out the flue. My highest flue temp was over 1200F when I used some pressed sawdust blocks. I used 5 with a couple of stringers underneath them. The blocks took a while to get going, but when the stringers ignited the blocks soon followed. Big inferno. But the heat did not transfer into the stove top. It went up and out the flue.

It puzzles me that you have STT greater than or equal to the flue temp. I also see that in @begreen's fire staring tutorial where his stove is cruising at 613F Flue and 625F SST.

I am hoping to hear back from SBI soon. I replied earlier this week to some questions they ask me. Hopefully thay can shed some light o this. (but I'll settle for heat, not light)

I think they added it to protect the stovetop from flames