I installed the new cat last Monday (6 days ago). It seems to be working better than the cat I pulled out, but I think the cat I removed was essentially fine, and the new cat hasn't impacted any of my issues, unfortunately. I'm glad I did the swap regardless, as part of troubleshooting.

I think I'm at the end of my rope on this, which sucks, but it seems like there's either something going on that I just totally don't understand, or that I can't control. Maybe both. I don't think there's anything wrong with the stove, and I can't figure out what's wrong with my methods or materials, so I just feel stuck.

What I have found works best both in terms of avoiding smoke puffing into the house and less smoking out of the chimney is as follows. The results are the most consistent I have achieved so far, but the outcome is still only really good maybe 50% of the time, and I don't know why that is.

1. Load the firebox N/S with kindling on the left side of the box

2. Start the fire on the left side of the box with intake full open and door cracked

3. Once the left side of the box is lit enough that there are decent flames and shutting the door doesn't seem to starve them, shut the door and leave the intake full open. This is usually after only a few minutes. This goes against everything I have ever heard about how to warm up a firebox, but it's what's working more often than not.

4. Run the stove like that until the cat reports temps over 500. This seems to take about 40 minutes, but depending on how well the fuel lights off during this time, it can require some fiddling to get the fire going well enough to get the cat hot, but not running so well that I've got too much fuel burning. It's also a little tricky since fire is only burning to one side of the firebox, and the temp sensor for the cat is on the other side. Presumably the cat is being heated somewhat unevenly during this time, which is probably not great.

5. Engage the cat and wait a bit to ensure the temp is going up / staying hot enough that the cat is engaged, then turn the intake down to 1/2 and watch the smoke from the chimney just to get a baseline

6. After a few minutes turn the intake down to about 1/3-1/4, confirm smoke lessens from the chimney and that the temps are still good / fire seems to be burning OK

Note that starting the fire on the left was a result of me playing with things, but also based on how the intake appears to work on this stove. There are two ports at the front of the stove on the inside of the box. When you slide the intake to full open, both ports are full open. When you slide it to full shut, the port on the left side of the box closes fully while the port on the right side stays maybe 1/3 open. The idea here was that as the fire dies down burning to the right and can benefit from more air without causing excessive smoking, it'll naturally be burning towards the port that's more open. Starting the fire on the right is also problematic because the temp sensor for the blower is on the left.

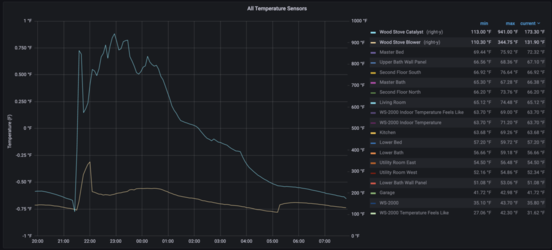

I had that working like a charm - I was super happy - for maybe 6 or 7 fires in a row. After step 6 there'd be hardly any smoke visible from the chimney, temps were great, and the glass stayed at least somewhat transparent for 2-3 hours before going opaque. But then I started running into issues where I couldn't get the cat warm enough to engage without getting pretty much the entire firebox going (which I know otherwise is what you'd expect), but then I'd be producing way too much smoke both in the firebox and out the chimney, which not only dirties up the glass and chimney, but keeps the temps cooler than I'd like. When this happens opening the intake more only makes it worse, and there's only so much better I can make it by turning the intake down, and it's still bad. This is essentially where the original question of "too much air?" came from. When thing are running really well, the cat will be somewhere between 800-1000 degrees for a few hours. When they are not going well (tons of smoke) it'll be in the range of 650-750 and for less time than when the temps are higher. Also when things are running well, the temp at my blower exhaust will be 220-250, and when they're not, it'll be 160-170 for a while, then raise to maybe a little over 200, then drop again. Everything is just way cooler.

I am not certain about anything but I am thinking that I have two primary issues.

1. Draft - If I get my stove really hot with kindling and a good coal bed before I really load it up, like most people would say is exactly what you should do, I can't close the door after getting the primary fuel going without getting puffing back into the house through the secondary air intake holes (at the top of the front of the stove near the cat). At that point the only way to mitigate is to shut the intake air way down, which just seems generally wrong. The glass goes opaque pretty much instantly and I still get a lot of smoke out of the chimney (same as described above in terms of playing with the intake). Interestingly during the kindling phase, I usually get very little smoke out of the chimney and the glass says clear. It's like with very little fuel in the box, things behave, but with any more, not even a packed box, they go south. Perhaps another interesting observation is that even if I start the fire slowly, if I leave the intake wide open, the fire will get to point, maybe and hour or two in, where it starts puffing into the house. It seems as though it finally gets hot enough that it starts gasping, basically. Point being, left to its own devices with the intake wide open, it will eventually start puffing even if it takes and hour or two, and even if it has been running well that whole time.

I think the issue is that once the fire is going really strong, even with the intake wide open, it can't pull enough air once the door is shut to properly fuel such a strong fire. Whether it's strictly the volume of air or that plus the impact of my altitude, I couldn't say, assuming I'm even right about this theory. If I start my fires so that they slowly build heat (as described above) I totally avoid the issue of puffing smoke back into the house. So basically I know how to mitigate the smoke in the house issue, but it just seems to go against everything you'd think you should do when starting a fire.

I am not sure if there's anything I can do to improve the draft. I don't think I can go higher with the chimney, at least not to any notable degree. I don't know if I could get the stove pipe replaced with something larger, but if I could, I don't know if that'd actually help, or if it'd maybe even make things worse. I have seen attachments for stove pipes that are basically blowers to force draft, but they look very sketchy and since this is an insert and the stove pipe is in a masonry chimney, I don't think there's anywhere I could install it, anyway.

2. Wood quality - As far as I can tell, for what that's worth (maybe less than I realize), my wood is fine. However, even with a relatively small amount of it burning, I often get way more smoke from the chimney than seems to make sense, and it doesn't get noticeably better once the cat is engaged, even with the new cat. Sometimes even if I crack the door and really let the fire rage super hard the amount of smoke pouring out of the chimney still seem extremely excessive. I don't know how to explain that other than to say it's the wood, but like I say, I have no idea what could be wrong with it. I'm not splitting every piece I put in to check moisture content, but as noted in this thread I have checked here and there and it seems fine. The feel of the wood (texture, weight, etc) also feels fine, at least as far as I am able to tell.

I can imagine how wood that's not seasoned well enough, too pitchy or too wet, would cause the smoke I'm experiencing, and how having less of it burning or hot enough to be giving off gas at any time would make the situation better, but again, I just don't see what's wrong with this wood. It is pine, which I know is generally pitchy, but I just can't make sense of this. When I get a really optimal burn going with very little smoke, the wood that goes into the box doesn't seem noticeably different to me than other times, but maybe it is, as I work through my stacks.

So at this point my strategy is to try my best to run fires the way I described above, and just accept that sometimes it's not going to go well and I'm going to have a ton of smoke. I hate that that's the case, but I am stuck. I did purchase the same type of chimney sweep (the kind that you use with a drill attachment) that my installer uses, and I cleaned the chimney out once basically just to get the experience under my belt, so I know I can do that throughout the season as necessary, it just sucks that I should have to.

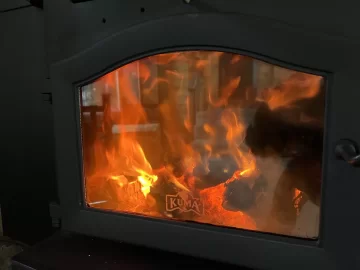

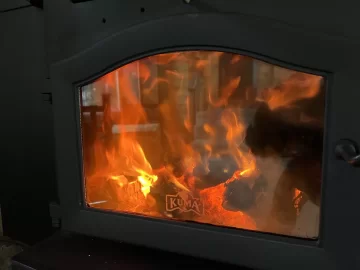

Just because I have them, I am attaching some video and pictures of how the firebox can appear to be burning well, but there's still tons of smoke pouring out of the chimney. The filenames explain the images. This is from this morning.

¯\_(ツ)_/¯

(╯°□°)╯︵ ┻━┻

If anyone has any thoughts I continue to be all ears, but I realize this probably sounds crazy, like there's something obviously wrong with my methods or materials that you'd see if you were here, that I am not picking up on. I suspect that the opinion will be "bad wood".

Update: I just reloaded the wood rack in my house in the way I normally do, but I measured the moisture content in literally every piece of wood, including splitting larger pieces to measure from the inside. Most everything is 14-17. A few pieces were 17-18. One was a bit over 19. I left that one, and one or two of the ones closer to 19, out. But overall, this seems to agree with what I checked before, just spot checking, and seems, to me, reasonable.

Thanks again for the all input so far. I know I must sound like I'm crazy.

Andy