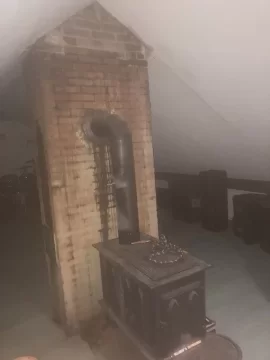

I have a big antique cast iron wood stove in my attic (which is my sot of men's club with my drums, etc.). It is a completely unheated room. It gets only occasional use and I want to be able to fire up the stove just for times when hanging out there.

The stove is up against a masonry chimney and has stovepipe that goes up, and through a 90 degree elbow into the chimney (typical). The chimney is completely unlined old brick. The obvious answer is a stainless steel liner.

However, is it any better or any worse to just go from the stove straight up through the ceiling (just a few feet above the stove) into some tripe wall insulated class A chimney pipe?

I don't think the difference in material costs is going to be significant. I like the idea of going straight out (especially on a short chimney). The only thing worrying me is cutting through an old metal roof, as people around town (who like to talk but know nothing) say that cutting a hole is nothing but problems and it will always leak. I did a ton of work in the Yukon for many years, and nearly everybody had such triple wall chimney pipe and they worked well and I never heard of leaking being prevalent.

The advantage of using the masonry chimney is mostly cosmetic (both inside and outside). It is also very easy and I can have the thing connected right away, rather than waiting until summer to play around cutting holes. I do need to use the chimney for other things one existing liner and probably need to add a second, but it is so huge that I may be able to fit this third liner in there.

The stove is up against a masonry chimney and has stovepipe that goes up, and through a 90 degree elbow into the chimney (typical). The chimney is completely unlined old brick. The obvious answer is a stainless steel liner.

However, is it any better or any worse to just go from the stove straight up through the ceiling (just a few feet above the stove) into some tripe wall insulated class A chimney pipe?

I don't think the difference in material costs is going to be significant. I like the idea of going straight out (especially on a short chimney). The only thing worrying me is cutting through an old metal roof, as people around town (who like to talk but know nothing) say that cutting a hole is nothing but problems and it will always leak. I did a ton of work in the Yukon for many years, and nearly everybody had such triple wall chimney pipe and they worked well and I never heard of leaking being prevalent.

The advantage of using the masonry chimney is mostly cosmetic (both inside and outside). It is also very easy and I can have the thing connected right away, rather than waiting until summer to play around cutting holes. I do need to use the chimney for other things one existing liner and probably need to add a second, but it is so huge that I may be able to fit this third liner in there.