Woodcutter Tom

Feeling the Heat

This is my communications with SBI regarding the stainless steel sheet. This is from an email thread in April of 2021.

Me:

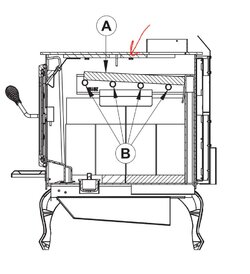

One other question. There is a steel sheet welded to the underside of the stove top. You can see the edges of it in the attached picture. It extends to within one inch of the left and right sides of the stove top. And fully front to back. Could you please tell me the purpose of this piece? See Picture. ( I attached a picture similar to the one above.)

SBI:

Hello,

This sheet is a top protector.

It create an air shield between the stainless metal plate and the top of the stove.

Thank you.

Me:

Does this prevent my stove top from reaching the expected temperatures??

I do not get the expected temperatures from my stove. Is this the reason?

SBI:

Hello,

No this metal sheet is not the problem that is 100 % sure.

If your not getting the expected result with your stove you should contact the technical support, they will help you understand what is going on with your stove.

The # is 1-877-356-6663

Thank you.

===========

I also am thinking that the stainless steel sheet impacts the STT in a negative way. I am not ready to remove it...or a portion of it...as I would like to keep the stove 'stock'. I only have experience with wood stoves for 60 months...SBI has 60 years. But......

Me:

One other question. There is a steel sheet welded to the underside of the stove top. You can see the edges of it in the attached picture. It extends to within one inch of the left and right sides of the stove top. And fully front to back. Could you please tell me the purpose of this piece? See Picture. ( I attached a picture similar to the one above.)

SBI:

Hello,

This sheet is a top protector.

It create an air shield between the stainless metal plate and the top of the stove.

Thank you.

Me:

Does this prevent my stove top from reaching the expected temperatures??

I do not get the expected temperatures from my stove. Is this the reason?

SBI:

Hello,

No this metal sheet is not the problem that is 100 % sure.

If your not getting the expected result with your stove you should contact the technical support, they will help you understand what is going on with your stove.

The # is 1-877-356-6663

Thank you.

===========

I also am thinking that the stainless steel sheet impacts the STT in a negative way. I am not ready to remove it...or a portion of it...as I would like to keep the stove 'stock'. I only have experience with wood stoves for 60 months...SBI has 60 years. But......