Hi Everyone, I'm impressed by the engagement and expertise here and am hoping for advice, expertise, and probably reassurance here.

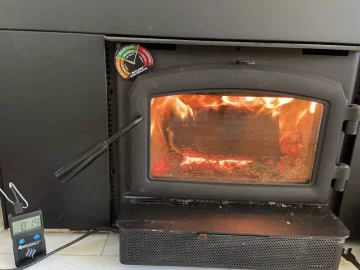

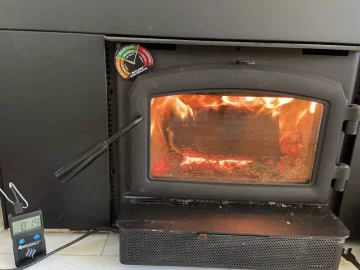

Last year I installed a Regency i1500 (LINK HERE) with a 6", uninsulated, 316ti stainless liner that is about 15-18' to the cap. Being a past firefighter I am leery of the temperatures shown on the digital readout which is a probe just above the catalyst where the flue collar meets the unit. I tried to operate it around 600 deg F to 850 deg F to avoid creosote and overfiring. After about 2 cords of dried maple (moisture <12% with my probe and split to check the insides) the cleaners that swept it this past summer said I had a lot of creosote build up. So I suspect I was running it too conseratively.

I've emailed my distributor, and Regency (the manufacturer) and asked about operating temps. The distributor wasn't much help, though I like the guy after about 5 emails back and forth he realized the unit I told him about initially was a catalyst and all his guidance was wrong earlier, and not really sure with this model.

Regency said the catalyst won't engage until about 500 deg, but to shoot for 700 and on a full load of wood the normal (probe read) operating temps are 800-1200 is typical. Generally I trust a manufacturer's guidance but they never really confirmed for me what is "overfiring" though they say "don't over fire the unit".

Using the rule of thumb that a stove top temp of 300-600 is generally good, and you can take your probe temp and cut it in half-I should have been in a good burning range when I ran it 600-850 last year, but come to find out I was making creosote. So my fears are 1) having a chimney fire, 2) overfiring the unit, 3) underfiring the unit and causing #1 eventually. This year I plan to sweep a couple times to really avoid any creosote build up and have been running higher temps (targeting 900 always).

So my question is: What temps do you all think I should be targeting with the probe reading? What's too hot, too cold? And how hot is too hot for a a 316ti liner?

If it helps, I'm in NH and heating seasons are about 6 months so I want to get this right as I have a family of young kids to keep safe and warm, and heating oil prices are too ridiculous to not burn wood mainly.

Last year I installed a Regency i1500 (LINK HERE) with a 6", uninsulated, 316ti stainless liner that is about 15-18' to the cap. Being a past firefighter I am leery of the temperatures shown on the digital readout which is a probe just above the catalyst where the flue collar meets the unit. I tried to operate it around 600 deg F to 850 deg F to avoid creosote and overfiring. After about 2 cords of dried maple (moisture <12% with my probe and split to check the insides) the cleaners that swept it this past summer said I had a lot of creosote build up. So I suspect I was running it too conseratively.

I've emailed my distributor, and Regency (the manufacturer) and asked about operating temps. The distributor wasn't much help, though I like the guy after about 5 emails back and forth he realized the unit I told him about initially was a catalyst and all his guidance was wrong earlier, and not really sure with this model.

Regency said the catalyst won't engage until about 500 deg, but to shoot for 700 and on a full load of wood the normal (probe read) operating temps are 800-1200 is typical. Generally I trust a manufacturer's guidance but they never really confirmed for me what is "overfiring" though they say "don't over fire the unit".

Using the rule of thumb that a stove top temp of 300-600 is generally good, and you can take your probe temp and cut it in half-I should have been in a good burning range when I ran it 600-850 last year, but come to find out I was making creosote. So my fears are 1) having a chimney fire, 2) overfiring the unit, 3) underfiring the unit and causing #1 eventually. This year I plan to sweep a couple times to really avoid any creosote build up and have been running higher temps (targeting 900 always).

So my question is: What temps do you all think I should be targeting with the probe reading? What's too hot, too cold? And how hot is too hot for a a 316ti liner?

If it helps, I'm in NH and heating seasons are about 6 months so I want to get this right as I have a family of young kids to keep safe and warm, and heating oil prices are too ridiculous to not burn wood mainly.