I have looked through countless threads but I have been unable to find a similar issue. I am running a USSC 6039 with the newer 4 button panel. I used this stove all last winter and had no issues with it. Before putting it in service this year I took it out and cleaned everything thoroughly. Took motors off cleaned fins, oiled shafts, bearings, blew it all out with a leaf blower. I thought it was good to go.

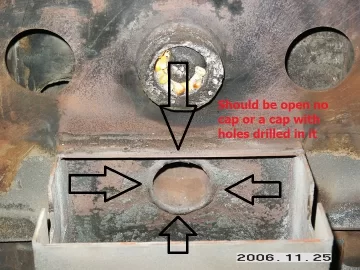

It fires up, motors all operate, and burns, produces heat. The issue I am having is the firepot is building up with incompletely burned pellets. Not enough to overflow or starve the fire as I check it regularly, not saying it couldnt but it has not happened yet. I have the FAK/OAK installed. I have tried pulling air from inside the building and outside but it does not really make a difference. Had the manual dampener opened 1/2, closed, fully open and I cannot seem to get the right burn. I have read through the "C" changes from the tech manual. I am not sure if the feed rate is off? I have tried resetting the board, it appears to have worked. But again incomplete burn. The only thing I changed was the exhaust path. Last year I had roughly 12" straight out the back to a 90, 2 1/2' vertical to another 90 and straight out. This year I removed the first 12" section and is now plumbed straight to a 90 and the rest is unchanged. Could this be causing poor air flow out of the exhaust not allowing proper draw?

Furthermore I have read that this stove burns corn or pellets and you need to change based on what you are running. What I have read on here is to push on and then both heat range buttons to swap this. I have been unsuccessful in getting anything to appear.

TIA for any help!

It fires up, motors all operate, and burns, produces heat. The issue I am having is the firepot is building up with incompletely burned pellets. Not enough to overflow or starve the fire as I check it regularly, not saying it couldnt but it has not happened yet. I have the FAK/OAK installed. I have tried pulling air from inside the building and outside but it does not really make a difference. Had the manual dampener opened 1/2, closed, fully open and I cannot seem to get the right burn. I have read through the "C" changes from the tech manual. I am not sure if the feed rate is off? I have tried resetting the board, it appears to have worked. But again incomplete burn. The only thing I changed was the exhaust path. Last year I had roughly 12" straight out the back to a 90, 2 1/2' vertical to another 90 and straight out. This year I removed the first 12" section and is now plumbed straight to a 90 and the rest is unchanged. Could this be causing poor air flow out of the exhaust not allowing proper draw?

Furthermore I have read that this stove burns corn or pellets and you need to change based on what you are running. What I have read on here is to push on and then both heat range buttons to swap this. I have been unsuccessful in getting anything to appear.

TIA for any help!