I was planning on hooking the OWB I am buying into the furnace directly with no heat exchanger. Is this a good way to do it? I was talking with someone and he said to find out if doing it this way would corrode my oil furnace. Can you successfully run a system like this? Does water treatment become a bigger issue so I will not rust my furnace? Any thoughts? My OWB will be considerably higher than my existing furnace. I ordered a Shaver 165 model.

Hooking OWB into oil furnace-no exchanger

- Thread starter knteriele

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Nofossil

Moderator Emeritus

Most (if not all) OWBs are not closed systems, so there is a constant supply of fresh dissolved oxygen in the water. Indoor boilers are designed to operated with closed and pressurized hydronics, so that the water quickly becomes oxgen depleted and causes virtually no corrosion. Connecting your OWB directly will cause increased corrosion of your existing boiler as well as any other steel or iron components in the system such as circulator pumps.

Perhaps you could slow the rate of corrosion with appropriate water treatment, but the preferable course of action is to use a flat plate heat exchanger so the oygen rich water causes corrosion only in the OWB.

Perhaps you could slow the rate of corrosion with appropriate water treatment, but the preferable course of action is to use a flat plate heat exchanger so the oygen rich water causes corrosion only in the OWB.

WILDSOURDOUGH

New Member

NoFossil is correct- My Central OWB specificily states to not mix OWB water system with hydronic water system- for the very reason nofossil states...crosion.

Play it safe and keep the two 'systems' seperate- use a Heat Exchanger.

Play it safe and keep the two 'systems' seperate- use a Heat Exchanger.

heaterman

Minister of Fire

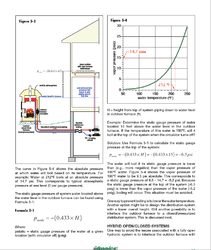

Not to mention that fact that it just plain won't work without elevating your OWB about 30 feet above the level of your oil boiler.

Think about it for a minute. Simple physics state that high pressure (your oil boiler @ 15 psi) goes to low (the OWB @ 0 psi)

Sorry my friend but you have to use a heat exchanger. They must be isolated from each other.

Think about it for a minute. Simple physics state that high pressure (your oil boiler @ 15 psi) goes to low (the OWB @ 0 psi)

Sorry my friend but you have to use a heat exchanger. They must be isolated from each other.

Jim K in PA

Minister of Fire

With all due respect to the other learned posters, there are many, many oil/gas fired boilers plumbed in series with an OWB or gasser. There are some variables and considerations to be aware of, but the use of an HX is not a fait accompli. I will be depressurizing my oil fired EFM furnace and plumbing the HWS from my GARN into the furnace. I only intend to do this for a season or two, as I will be incorporating a propane fired backup system next year, and eliminating the oil furnace entirely at that point.

If your existing pressurized oil furnace has a pressure switch in the control circuit, you must determine how depressurizing will affect the circuit. Otherwise, it will work in series with the OWB, with the caveat that increased corrosion is a potential. Even that can be managed with proper water treatment and prudent operation. Heat drives O2 out of solution, and there is very little surface area exposed to reabsorb O2.

When I was initially planning to purchase a CB6048, the Central Boiler dealer enthusiastically encouraged me to plumb the oil furnace in series and avoid the HX. That is the typical installation for CBs in our area.

Just another perspective, based solely on my own research, not personal experience. FWIW. My $.02. YMMV, etc.

If your existing pressurized oil furnace has a pressure switch in the control circuit, you must determine how depressurizing will affect the circuit. Otherwise, it will work in series with the OWB, with the caveat that increased corrosion is a potential. Even that can be managed with proper water treatment and prudent operation. Heat drives O2 out of solution, and there is very little surface area exposed to reabsorb O2.

When I was initially planning to purchase a CB6048, the Central Boiler dealer enthusiastically encouraged me to plumb the oil furnace in series and avoid the HX. That is the typical installation for CBs in our area.

Just another perspective, based solely on my own research, not personal experience. FWIW. My $.02. YMMV, etc.

heaterman

Minister of Fire

" the Central Boiler dealer enthusiastically encouraged me to plumb the oil furnace in series and avoid the HX. That is the typical installation for CBs in our area. "

Somehow that statement doesn't surprise me. The CB dealer in these parts does the same thing. I think they give them lessons on how to do it cheap..............not correctly. By and large the vast majority of OWB dealers I run into have very limited knowledge of the finer points and unseen pitfalls present in a hydronic system. Very few have much in the line of actual experience with hydronic piping.

I'm not saying that what you have proposed will not work but .........let's just say there's a big can of worms involved. The warranty on any normally pressurized system is void if it is operated "open". Call any of the manufacturers and speak with their tech dept.

PS:Nothing like a Garn!!

Somehow that statement doesn't surprise me. The CB dealer in these parts does the same thing. I think they give them lessons on how to do it cheap..............not correctly. By and large the vast majority of OWB dealers I run into have very limited knowledge of the finer points and unseen pitfalls present in a hydronic system. Very few have much in the line of actual experience with hydronic piping.

I'm not saying that what you have proposed will not work but .........let's just say there's a big can of worms involved. The warranty on any normally pressurized system is void if it is operated "open". Call any of the manufacturers and speak with their tech dept.

PS:Nothing like a Garn!!

Eric Johnson

Mod Emeritus

I've seen it done that way with an OWB and it seems to work OK. Corrosion is obviously a concern, as is other crap that can (somehow) get into open systems and clog up your previously-pressurized plumbing. Also, bear in mind that while you might get your hydronic system to work OK on the ground floor, you're not going to have much luck keeping water in the pipes on the second floor, if you have one. Remember, water above the level of the unpressurized OWB is going to want to flow out the overflow port. Flat plate heat exchangers are relatively cheap and they solve more problems than they create.

webbie

Seasoned Moderator

Stated simply, the OWB has to be higher than the highest radiator or pipe in the house. If that can be easily done, then it is possible the corrosion can be worked around.

Also, some delivery systems seem to need more pressure than others to stop air locks from forming and get to water up and around strange bends. It's tough to "bleed" a system with very low pressure. Ideally, such a low pressure system would be designed from scratch with larger piping and gentle turns, etc.

Also, some delivery systems seem to need more pressure than others to stop air locks from forming and get to water up and around strange bends. It's tough to "bleed" a system with very low pressure. Ideally, such a low pressure system would be designed from scratch with larger piping and gentle turns, etc.

Ncountry

Feeling the Heat

Stated simply, the OWB has to be higher than the highest radiator or pipe in the house. If that can be easily done, then it is possible the corrosion can be worked around.

Also, some delivery systems seem to need more pressure than others to stop air locks from forming and get to water up and around strange bends. It's tough to "bleed" a system with very low pressure. Ideally, such a low pressure system would be designed from scratch with larger piping and gentle turns, etc.

Funny ,.I know this is an old thread. I am doing some searches to learn a little more about hooking a wood boiler to gas boiler in series or parallel and I ran across this. I know of 2 -2 story homes(fil and grandfils) with central boilers outside at the same level as the basement floor. Water never comes out the vent.... even in the summer..I am curious now ,may have to do some checking into this.... Maybe because they run their circulator pumps 365 days a year, never giving the water a chance to gravity feed back out??

Bob Rohr

Minister of Fire

Funny ,.I know this is an old thread. I am doing some searches to learn a little more about hooking a wood boiler to gas boiler in series or parallel and I ran across this. I know of 2 -2 story homes(fil and grandfils) with central boilers outside at the same level as the basement floor. Water never comes out the vent.... even in the summer..I am curious now ,may have to do some checking into this.... Maybe because they run their circulator pumps 365 days a year, never giving the water a chance to gravity feed back out??

Yes the water will stay in the system above the level of an open OWF, as long as it does not have access to air to break the siphon. Put your finger over the end of a straw and pull it from a glass of water. The water will stay in the straw until an air bubble works it's way up to break the siphon.

This is how a drainback solar system operates also, it needs a way to get the air trapped in the drainback tank, or space to allow it to drain out. If not the water stays in the collector, freezes, and potentially splits the copper tube. been there, have the scrap copper absorber to prove it

Aside from voiding the warranty on your equipment that was designed to be pressurized, and the corrosion of ferrous components, flashing to steam is possible.

You have the potential to pull sub atmospheric conditions in the upper level piping. When you do this you lower the boiling temperature of the fluid. If you run the un-pressurized heater at elevated temperatures, above 180, then you could experience flashing.

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 415

- Replies

- 9

- Views

- 624

- Replies

- 3

- Views

- 2K

- Replies

- 17

- Views

- 3K