maple1

Minister of Fire

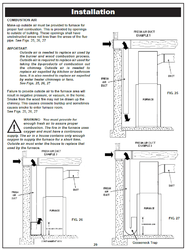

This is the type of damper I have. When the chimney is cold and a piece of paper is held against, it is blowing away from the damper resulting in a heavy downdraft.

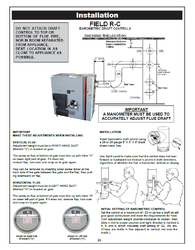

http://www.fieldcontrols.com/rc.php

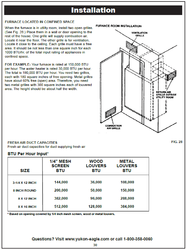

Now I"m way confused. I can't imagine how a chimney that tall can have backdraft like that.