Everything Drolet Tundra - Heatmax...

- Thread starter brenndatomu

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

trx250r87

Burning Hunk

Not when you switched furnaces in the middle of this winter!Just keep in mind, this is the WARMEST winter in the history of the world. Nearly impossible to compare performance from last year to this year.

I didn't get my first Tundra till Feb of last year anyhow. This year was really my first year using it then it got warrantied and swapped in the middle of this winter and literally right at the cold part of it about what 4-5 weeks ago guys is that right? I think it was middle to end of Jan when I made the swap. lemme see.. Date on my photo of new stove received was Feb 8th. The newer model comparison was good I feel as both had been ran thru out the coldest months of this season alone. If I remove the rest of the flex I had to use and get solid in, with the rest of the modifications I did this year to the stove and the ducting system, I feel pretty confident it will work well on a colder winter.

I didn't get my first Tundra till Feb of last year anyhow. This year was really my first year using it then it got warrantied and swapped in the middle of this winter and literally right at the cold part of it about what 4-5 weeks ago guys is that right? I think it was middle to end of Jan when I made the swap. lemme see.. Date on my photo of new stove received was Feb 8th. The newer model comparison was good I feel as both had been ran thru out the coldest months of this season alone. If I remove the rest of the flex I had to use and get solid in, with the rest of the modifications I did this year to the stove and the ducting system, I feel pretty confident it will work well on a colder winter.Sorry to confuse if I did. I am not allowing the controller to operate at flu temps of 800. The flu only nears 800 on startups when I have the timer running overriding the bypass switch. The high limit switch usually shuts the stove down around 750 or so it only has hit 800 or 820 for a few seconds if I leave the door open too long after loading. Usually try to leave door open about 30 secs or so or until flu reaches around 400 before locking it and letting timer and controller take over. So I don't get all smoked up in the firebox. If I wait too long like a minute the flu can get to hot. The other factor is the timer setting. I have learned to set it to only 20 mins instead of 25-30 on full load startups. This keeps flu from getting over 750. If I set timer for 25-30 flu can hit 800-820 before high limit switch fires. The controller is set to close damper around 500-600 and open around 200-300. I do not have it wired properly to have the 2 separate limit settings. just high temp and low temp thats it. works well for me. Only problem I have is probe is cheap and temps are wrong and all over the place. I have a good multimeter that measures accurate flu temps with its prob so I just adjust mypin to function based of readings from multimeters probe.Nice report @Digger79 . You're one step ahead, I'm finding similar results even if on my older model Tundra. That by starting to burn the coals a few hours into the burn, once most offgassing from my box elder is finished, that it's easier to keep the house warmer. I originally had used the "burn coals" switch just for cold days, but now I'm using it on warmer days too, and it just seems to improve the overall cycle and heat.

800F on the chimney still seems rather hot as a general practice. I don't think you're going to lose much heating power by lowering your controller to 600-650, but would probably save potential wear-n-tear on the furnace. I'd just hate to see problems that could be easily avoided.

Last edited:

And thanks for the warning, I know you've ran these things for a while so pretty familiar with the safe operating temps. I will try getting my controller up to the 600-650 range possibly I think I been around 5-600 on shut down recently but rem I don't have the second high/low setting like you do. seems all I really need is the low setting at the right spot so that damper opens when draft gets low. The high setting when damper closes can vary quite a bit with little change in results. The only change I get there is a littler better heat in the house if the High/close damper setting is set a little higher. I will warn folks if they gotta be careful with the T stats. the high limit on this one seems to work well but SBI should never have sold stoves with the intention of people using therms with out getting a solid safety shutdown control on the furnace period. Seems they kinda figure that out by now and people should be pretty safe and using therm on a cold house now should be ok.. unless snap disc fails. lol. Thats where the baro can help. Seems to be the best safety you can put in. mechanical.Nice report @Digger79 . You're one step ahead, I'm finding similar results even if on my older model Tundra. That by starting to burn the coals a few hours into the burn, once most offgassing from my box elder is finished, that it's easier to keep the house warmer. I originally had used the "burn coals" switch just for cold days, but now I'm using it on warmer days too, and it just seems to improve the overall cycle and heat.

800F on the chimney still seems rather hot as a general practice. I don't think you're going to lose much heating power by lowering your controller to 600-650, but would probably save potential wear-n-tear on the furnace. I'd just hate to see problems that could be easily avoided.

The little metal reflector I made from high temp duct tape marking the manometer is for the camera. So I can see the draft remotely. I have a remote control over everything so I can shut the controller off and control the T stat wireless or just shut everything down thru the power if something fails or goes wrong. I have yet to do it but have ability to set alarms that will instantly tell me on my phone if something is going wrong with the stove. Say a stray cat comes in and the two of them manage to knock something into the glass and break it open during a hot fire.. yikes! far out I know but if It happens I will know about it instantly if I get my chit in gear and rig up the alarms.

I feel it is important to notate that the high limit switch comes on much later like at flu temps of 800-820 on during startups such as a top down fire or loading a full load on a hot coal bed and letting that surge up.. naturally the flu can get much hotter much faster than the firebox itself and the rest of the furnace as well outer areas of the plenum. This is why the timing on the timer switch for the bypass is crucial. After fire box is warmed up or initial surge is over with from the full load.. the high limit switch will shut down the damper much sooner like around 650-700. This is why I keep saying the controller is not really doing much as the snap disc seems to operate at those temps anyhow after stove has been fired up. However controller will keep it closed for me of course for longer secondary burns after the snap disc shuts back off so it does have some function for sure and ensures damper opens at low draft despite any other factors such as heat demand. I got a nice mix of the T stat helping the loads burn to their full potential and the rest of the controls keeping the stove safe and at good flu temps. Just letting the thing cruise and not using a T stat to call for some heat, results in a colder house period. The wood consumption actually has gone down when I burn hotter fires cause I burn smaller loads. Trying to burn full loads over long periods of time simply resulted in a colder home with same or more wood consumption. I am thinking however the longer secondary burns could be more useful during the warmer weather however. In cold weather the hotter fires give more heat w less wood but in mild weather might be nice to have it cruise on low for a long time. I dunno prob not. this would simply keep us from lighting fires cause we would keep good coals but burn more wood than we need. getting lazy. likely in mild temps to use less wood and get good heat simply building even smaller fires and having to restart fires would be the key to reducing wood consumption while keeping heat demand. less work than splitting and stacking more wood I would think.

Last edited:

Hmm, that's a good question. Normally they say if the chimney is inside the house and structurally sound that you don't have to insulate but it is still a good idea because there is no way to know if it was really built properly as far as clearance to combustibles. Also, unless you have had a sweep come in and give the full length of the chimney a camera inspection it is still a good idea to insulate just because you never know where a crack is starting. You and your family are going to bed with a fire in the house you know...respect the fire.

I'd insulate the full length...

wow. cool looking back a few years on this thread I can see some of your learning process too. Even though you still recommend the insulation of the chimney you had to same belief I did at the time of this post.. That insulating the pipe if inside a clay lined chimney was not necessary. U still recommend it for safety but did not mention the heat loss you explained to me in mid winter of 2016. I still have the single wall pipe thru my masonry liner with a insulated cap at the top now, after your lessons on heat loss. It does return for a while but I know now that if I get the insulation and insulate that pipe I will get less heat loss, stronger draft longer. It currently does pull hard but looses its draft of course as pipe cools off. I though the insulation of the air around the pipe in the clay liner would be enough to maintain the best draft. Nope. Need the insulation rt on the pipe. Im enjoying going back to the beginning of this thread and reading all these things I had not seen, everyone's progression thru out the last few years with these things. What and Awesome thread Brenndatomu and amazing how long its been alive and stays alive! Nice work bud.

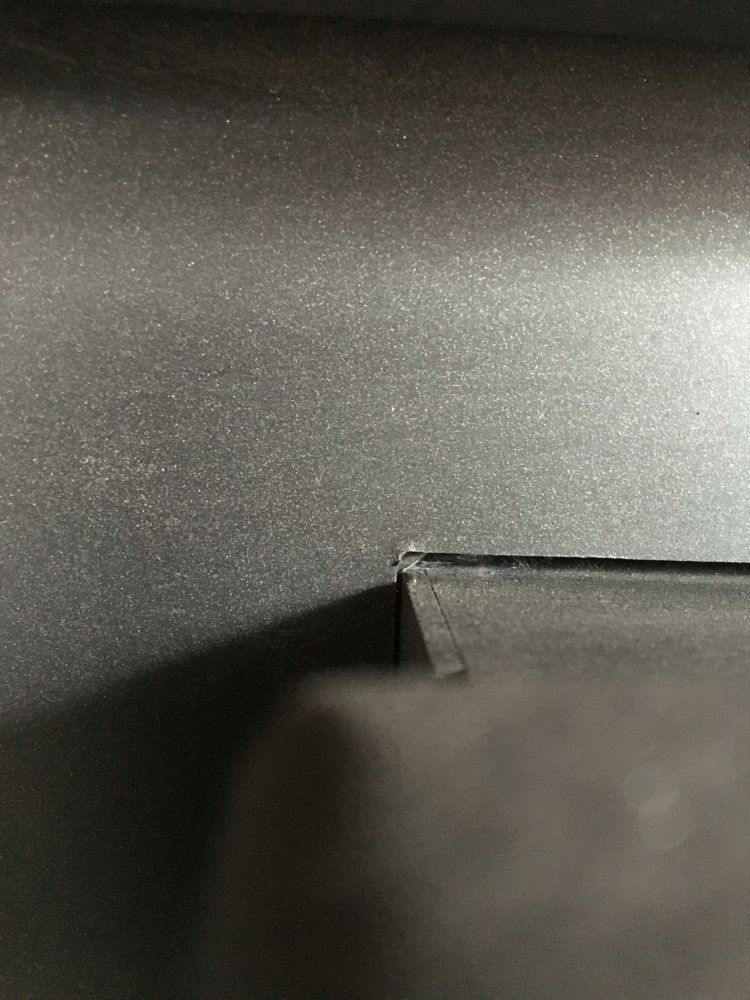

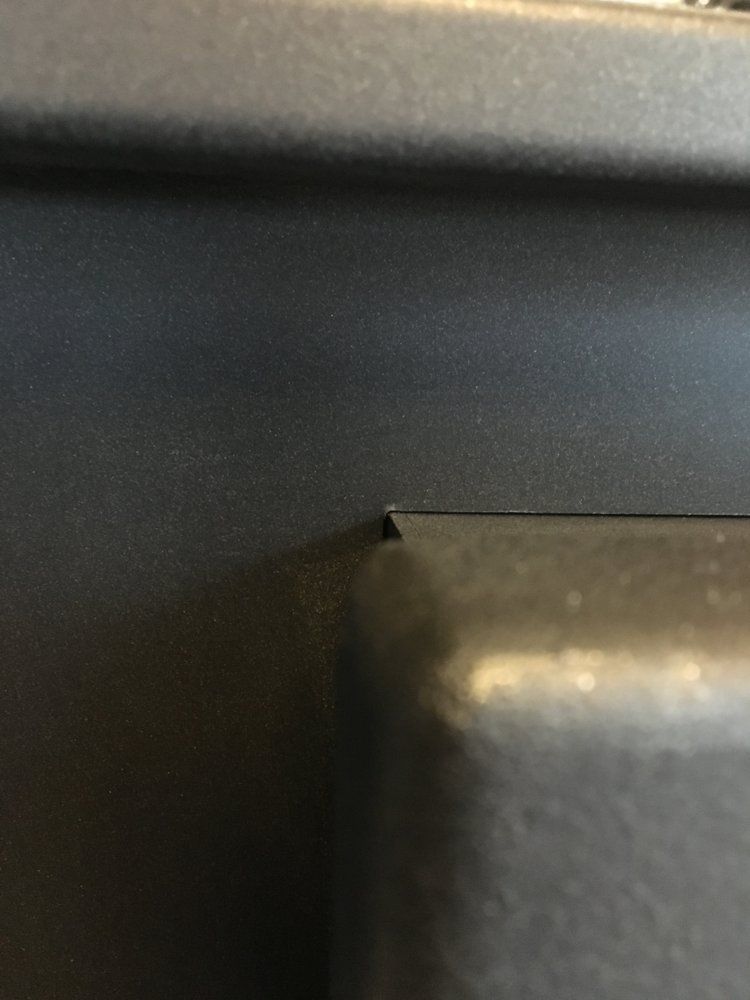

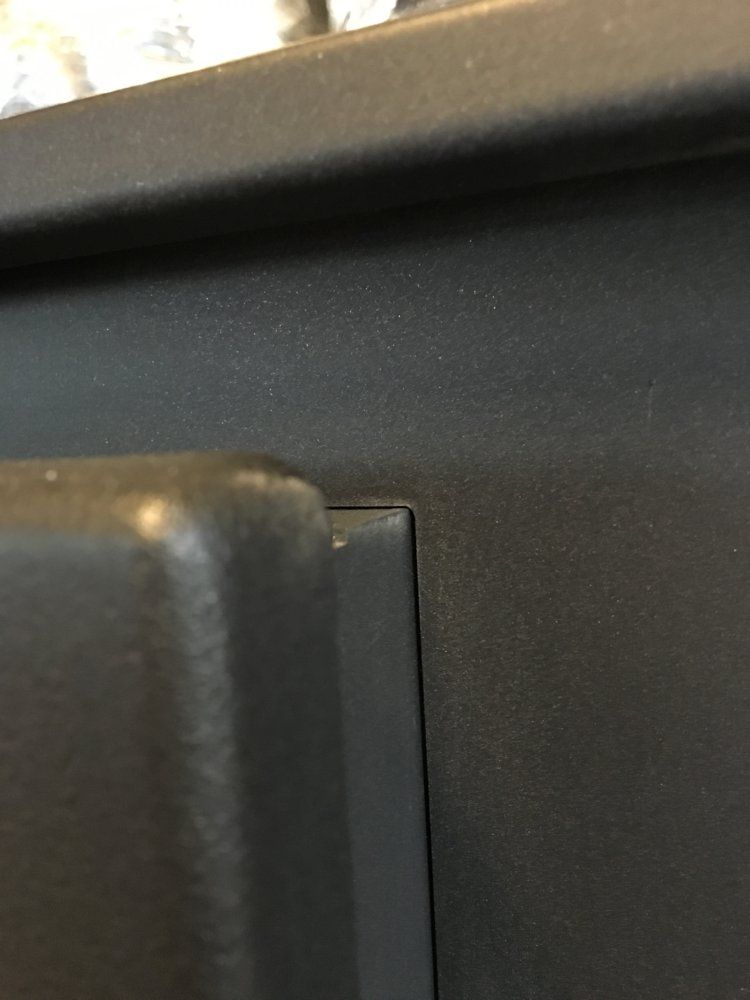

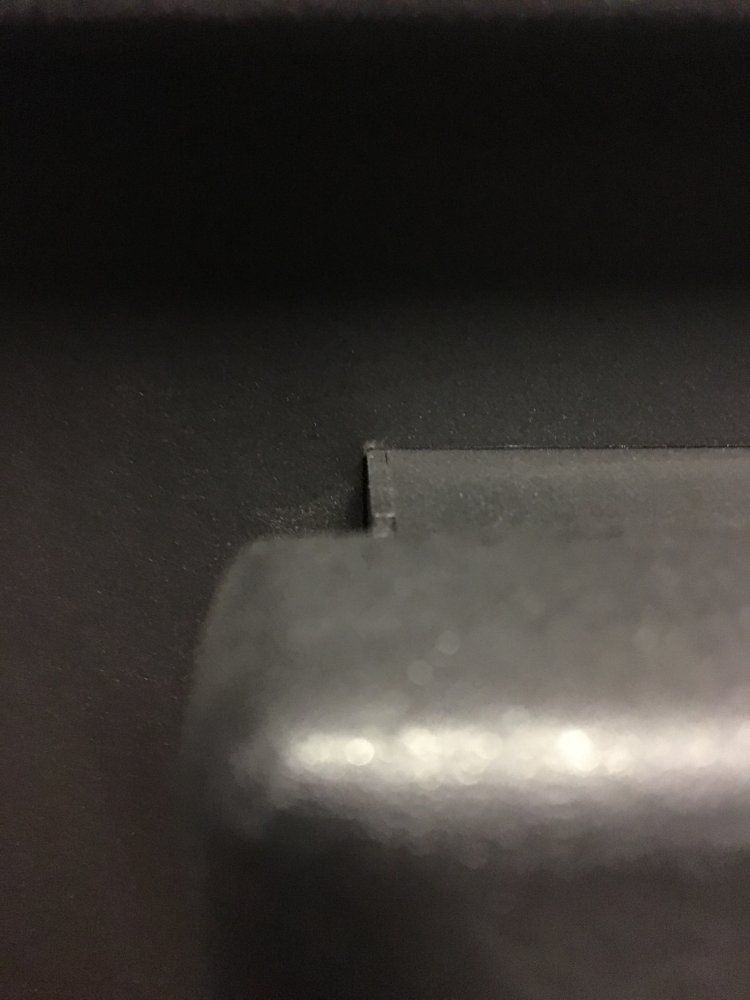

I do not believe that damper being cracked like that is factory setting. matter fact I am pretty sure of it. I have owned two of these units now. 1 made in 2013 and the other 2015. both units damper was designed and set up to shut all the way. The changes they made were the size of the air intake holes. not the door staying open. That is incorrect and I think the rod is bent or something is hanging it up.View attachment 154116 View attachment 154117 View attachment 154118 View attachment 154119 View attachment 154120 I wanted to share something. I have one of the first couple hundred Tundra's made. A couple weeks back I was at Menards and noticed on the new Tundra's the damper door was redesigned. I emailed SBI and they sent me the new door. It comes with some sort of shiny metal insert and the new door. The new door is redesigned in a fashion that when it closes it stays open partially thus always letting in some air. Here are some pictures of the old and new.

I currently have the updated model tundra built in 2015. Designed to run much cooler than the original and it does. In the first couple of firings that were very small fires to break the stove in.. the paint blistered at the top corners of the firebox. The flu was only hitting temps of around 5-600 at that point.. I have firebricks lined up the side of the door opening and after seeing the blistering stuffed the corners with rock wool to totally protect those corners. I posted those pics around page 55-60 somewhere can't rem but stuffed rock wool above firebrick to fill in below heat shield at top corners of firebox door. Now these blisters occurred when face of stove barley hit 300 on the cheap magnet therm. I tested those therms I am using and they only vary by about 50 deg. So if you had face temps reading 400 and a heat gun saying 600 that means your flu was possible roaring up above 800 internally. not good. The stove paint is suppose to withstand temps of 1300-1500 but never does. sand down and repaint every year to prevent rust from forming and paint blisters are not a cause for concern but should draw your attention to just how hot you are letting the furnace run. These are just my thoughts and opinions, I know I sound like a authority/know it all but I'm certainly not. Just what I currently believe to be correct. This thread has constantly changed my methods of thinking and corrected improper understanding several times. lolCurious if anyone else has paint peeling on the front of their Tundra? See pictures below at top left of door.

In Wisneaky's post #3, he reports 325F-400F on the front of his furnace. I'm getting the same at the same measurement location with my thermometer (that I don't necessarily trust, IR thermometer on order) which has indicated as high as 600F over the spot of peeling paint. The below pictures were taken quite a while into a burn, within a few minutes of each other, so temps had stabilized.

I don't know if 600F is common to peel paint?

View attachment 155224 View attachment 155225 View attachment 155226

Jacksprat

New Member

I currently have the updated model tundra built in 2015. Designed to run much cooler than the original and it does. In the first couple of firings that were very small fires to break the stove in.. the paint blistered at the top corners of the firebox. The flu was only hitting temps of around 5-600 at that point.. I have firebricks lined up the side of the door opening and after seeing the blistering stuffed the corners with rock wool to totally protect those corners. I posted those pics around page 55-60 somewhere can't rem but stuffed rock wool above firebrick to fill in below heat shield at top corners of firebox door. Now these blisters occurred when face of stove barley hit 300 on the cheap magnet therm. I tested those therms I am using and they only vary by about 50 deg. So if you had face temps reading 400 and a heat gun saying 600 that means your flu was possible roaring up above 800 internally. not good. The stove paint is suppose to withstand temps of 1300-1500 but never does. sand down and repaint every year to prevent rust from forming and paint blisters are not a cause for concern but should draw your attention to just how hot you are letting the furnace run. These are just my thoughts and opinions, I know I sound like a authority/know it all but I'm certainly not. Just what I currently believe to be correct. This thread has constantly changed my methods of thinking and corrected improper understanding several times. lol

Jacksprat

New Member

will be going to pick up my Drolet Tundra wed next week. Was wondering if any of you have pictures of how the stove is crated. I have a 150 mile trip with the furnace and want to be sure I have adequate tarping etc for the trip. thanks

I could be wrong but keep in mind if surface temp of steel is 600 its likely the middle of the steel panel and the inside is much much hotter of course. The temps we are measuring are just whats coming off the outer surface of the steel so its probably much hotter than we may think? The key I think as Double D explained to me much later in this thread is to keep flu from getting over 800 ever no matter what. Paint will peel at temps well below 800 on the chimney. mine did and its barely hit 800 a few times in the flu. usually is kept at 750 or less on average.Unfortunately, no. Paint started peeling long before I applied the thermometer.

I do often run the furnace with the damper wide open to get the house up to temp or to keep things simpler for the wife. Also, to get the wood dry enough in only one year I split it kind of small, and it seems to offgas too much if I load the entire firebox. So we've done a lot of small (1/3 firebox) fires with damper open. Still learning, and getting smarter about how to keep it closed more.

So I might have overfired at times, but I can't imagine by much; smaller loads with a baro damper at -0.05 inches.

Thanks for volunteering and showing the picture, haven't seen one yet.

Any tips for how to attach it? Could you use existing screw holes, or was it better to drill new holes?

Are your snap discs still on the back of your furnace? Mine are on top, and I've wondered if would be a problem to put them (and specifically the wires) so far inside the plenum in a power outage. I suppose one might argue that mine are also in a small plenum--the steel protective cover.

DoubleB

Minister of Fire

So if you had face temps reading 400 and a heat gun saying 600 that means your flu was possible roaring up above 800 internally. not good.

Maybe. But I think it doesn't work that way, because the heat exchanger cools the gases down before they get to the flue. For example, the face temps at the top corners of my loading door (above the front firebrick that I added) actually get even hotter (up to 750F) when the damper is closed and a full load is cruising on the secondaries. But the flue is not hot (I can even touch the single-wall black stove pipe).

Welcome Jack! It comes in a crate a couple inches wider and longer than the furnace (with the blower attached) IIRC, the sides are covered with plywood and then the whole thing is covered in plastic. IMO, if you have a 10' x 12' (or a little bigger) that should be plenty to cover any shipping damage of the plastic...may wanna take a roll of duct tape too, just in casewill be going to pick up my Drolet Tundra wed next week. Was wondering if any of you have pictures of how the stove is crated. I have a 150 mile trip with the furnace and want to be sure I have adequate tarping etc for the trip. thanks

its different on startup. flu gets much hotter first long before box gets warm. I see what you mean though and I am pretty sure the paint peeling thing does happen later not on startup so my guess is your right the flu's not getting all that hot. 600 surface temp just sound damn hot I dunno. mine never really got over 400-500 on the magnetic therm and there within bout 50 deg of accuracy Im pretty confident by now. And my paint blistered anyhow. lol.Maybe. But I think it doesn't work that way, because the heat exchanger cools the gases down before they get to the flue. For example, the face temps at the top corners of my loading door (above the front firebrick that I added) actually get even hotter (up to 750F) when the damper is closed and a full load is cruising on the secondaries. But the flue is not hot (I can even touch the single-wall black stove pipe).

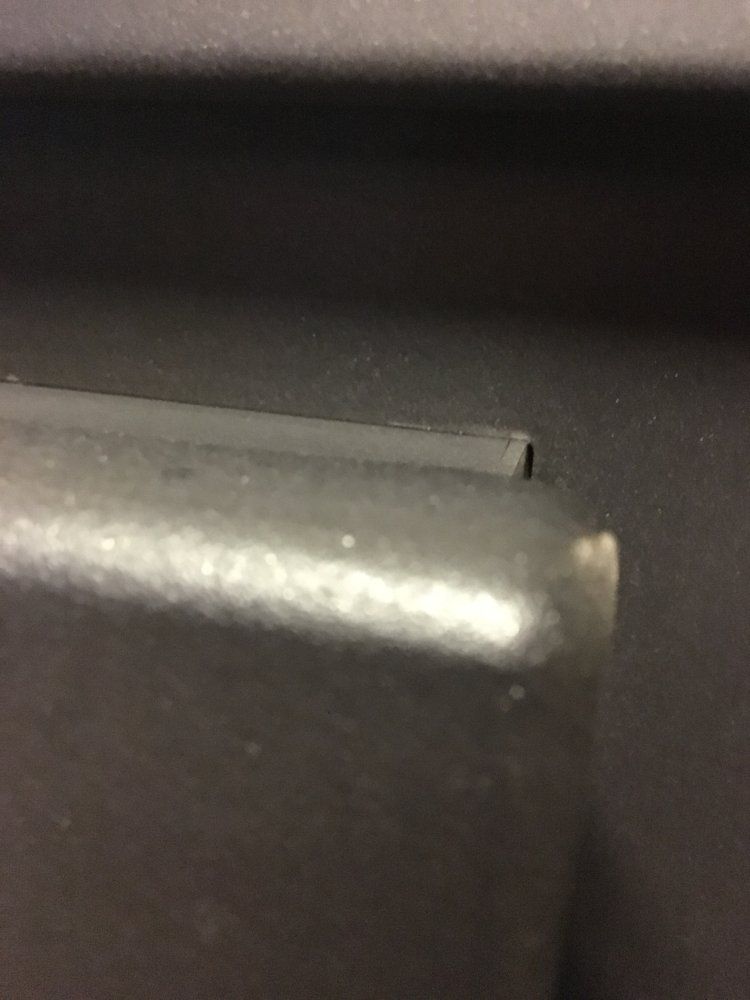

Well anyways here's a few pics of the newer model 2015 Tundra's heat exchanger's cut out. You can see the gap is fairly large when cool, notice the smushed upper left corner from the HE expanding into the plate. These pics show the difference in the gap as HE expands and contracts. No wonder the first one cracked being welded plus no room to expand. Course problem as well was the firebox itself which has been corrected w multiple measures, i still say the new high limit is the main butt saver there.

Cold

Warm

Hot

Cold

Warm

Hot

Attachments

So as you can see now there is room. a cut out with a gap for the HE to expand. If you look close at the pics above you can see they used gasket rope to seal the air from blowing through. The cut the cutout a little bigger, used a covering plate that stops just below the HE door and sealed it with the gasket rope. Did same thing to the damper cut out. Some one mentioned measuring and posting pics of this movement on and old one after it had cracked I think Brenndatomu maybe. Anyways this is close.

Apparently notDoes anybody know if the tundra qualifies for tax credit in usa?

http://www.drolet.ca/upload/file/Drolet_IRS 2016.pdf

It seems the HE expanding outward was as much or more of a problem as it expanding front to back. It does move some in and out from the cut out into the stove but there is more vertical movement than anything. So just cutting welds on older units may not help completely. Making a cover plate, cutting a space around the HE door, and covering with a plate and high temp gasket to seal crack around HE would be the best fix there.

Jacksprat

New Member

thanks a lot for the info pick up should be ok getting it in the house and down the stairs OOUCHWelcome Jack! It comes in a crate a couple inches wider and longer than the furnace (with the blower attached) IIRC, the sides are covered with plywood and then the whole thing is covered in plastic. IMO, if you have a 10' x 12' (or a little bigger) that should be plenty to cover any shipping damage of the plastic...may wanna take a roll of duct tape too, just in case

!!

!!Jacksprat

New Member

well just got home with my new Drolet Tundra and while at the store they loaded a new Champion logsplitter on my trailer will assemble spitter tomorrow and will have to wait on the furnace have friedns coming over for a few days the Champion logsplitter is a 22 ton with a multi splitter in the USA it is 20 ton anyone have one comments would be appreciated thanksthanks a lot for the info pick up should be ok getting it in the house and down the stairs OOUCH!!

Free splitter with the purchase of a Tundra day? What fortunate timing!well just got home with my new Drolet Tundra and while at the store they loaded a new Champion logsplitter on my trailer

I have a 23 ton champion (looks the same as a 22T) It works fine...haven't had any major issues with it in the last 3-4 years that I've had it...it does a fine job...but I'm not head over heels in love with it either...rated 1-10, I'd go a 6 or 7...Rural King of Ohio had 'em on a killer black Friday sale when I bought it, so the price was right for what it is I suppose. I wasn't even planning on buying a splitter as I had use of my brothers splitter whenever I wanted it and I was planning on building a flywheel splitter...so I bought the Champion "just 'til I get mine built...then I'll sell it for break even"...yeah right. Haven't had the time or the notion to build a splitter since...I think the Champion has found it's "forever" home!

Jacksprat

New Member

just contacted Drolet and they said my Tundra was made in 2015 and has an upgrade for the front of the firebox anyone know about this upgrade any thing else I should look for?????? thanksFree splitter with the purchase of a Tundra day? What fortunate timing!

I have a 23 ton champion (looks the same as a 22T) It works fine...haven't had any major issues with it in the last 3-4 years that I've had it...it does a fine job...but I'm not head over heels in love with it either...rated 1-10, I'd go a 6 or 7...Rural King of Ohio had 'em on a killer black Friday sale when I bought it, so the price was right for what it is I suppose. I wasn't even planning on buying a splitter as I had use of my brothers splitter whenever I wanted it and I was planning on building a flywheel splitter...so I bought the Champion "just 'til I get mine built...then I'll sell it for break even"...yeah right. Haven't had the time or the notion to build a splitter since...I think the Champion has found it's "forever" home!

jacksnipe

Member

Concerning the shipping crate, is the furnace crate standing up strapped to a pallet or is is laying down on it's sideWelcome Jack! It comes in a crate a couple inches wider and longer than the furnace (with the blower attached) IIRC, the sides are covered with plywood and then the whole thing is covered in plastic. IMO, if you have a 10' x 12' (or a little bigger) that should be plenty to cover any shipping damage of the plastic...may wanna take a roll of duct tape too, just in case

It's shipped standing up, in its "normal" positionConcerning the shipping crate, is the furnace crate standing up strapped to a pallet or is is laying down on it's side

Similar threads

- Replies

- 15

- Views

- 17K