Bubblehead huh? I did 5 yrs on a carrier as a nuke ET - finished construction, testing, initial startups, etc, then did 3 yrs of radcon & maintenance on subs before I got out.

Go to the link that Whiplash posted, about 1/2 way down the page is the video tab. Once the video player shows up click the little icon below it. The video seemed easier to follow than the written instructions.

How many seasons (cords) did you have on your old 200 before it failed? How / where did it fail? Was it the all carbon steel firebox?

Progress on installing my 100 has been very slow. New job position, lost our beloved sheltie to pancreatic cancer, got 2 new sheltie puppies, both parents had some health issues, etc.

Mustash29,

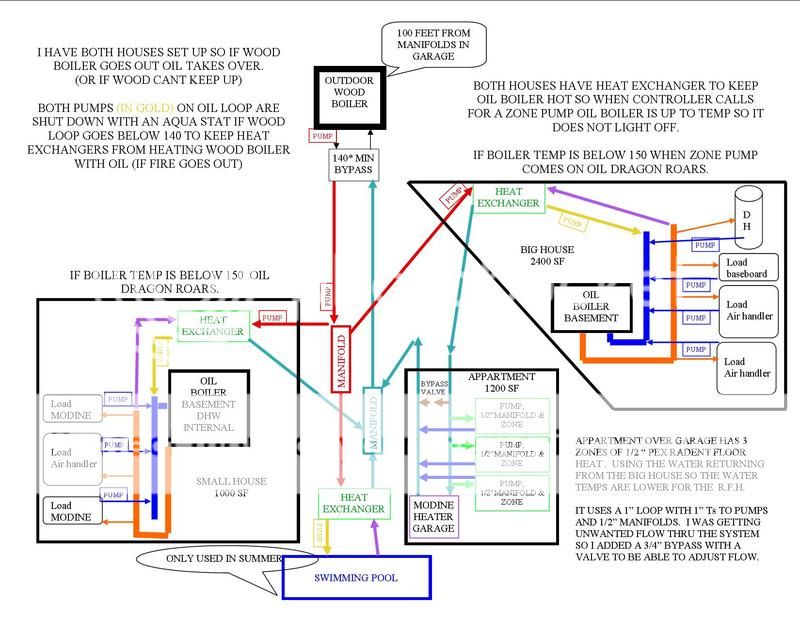

I did 6 years surface QM before doing a couple more on subs. Finished with 11 years and started a portrait business in Norwich in 88. Still love it, seasonal business so I have a lot of free time (or used to). Now I'm building a second 3 car garage with a 1200 sq foot apt above it for my daughter and granddaughter, it is almost done. It took longer than I ever expected, mostly because I go the wood boiler half way thru the build and shifted all efforts to installing it and getting 4 years ahead with wood.

I got most of my wood from the sides of the road at DOT cuts at first but I hooked up with a couple tree guys and would always come to help and haul away anything they wanted. I have become very good friends with a guy who bids jobs for both of us, he drops trees, I brush hog and haul away wood and get paid to boot.

My old 200 had its first season the year it was so cold a few years back, heated 2 houses to about 74* and we used no oil but blew thru 14 cord of mostly dry pine. Burned some fresh ash and some one season elm. All and all a rough season to start burning full time but oil was $4 a gallon and I hate giving money to people who hate us. My next door neighbor who works for me bought $3000 worth of oil that year for a smaller house and runs it at 64*. I think it saved us about $6000 in oil the first year between the 2 houses.

I got 2 seasons out of it, burn in summer also to heat the pool. It was cold rolled steel and when it gave out I never spent the time tearing it down to find the leak, just got the new one under warrantee with $2000 depreciation. They told me I could scrap the old one so I had a guy from Mass help me pull the old one and put the new one in place. He gave me $1500 to scrap the old one for me. I guess he was a maintenance man for a town or school or something. Said he was going to pressurize it to find the leak. I never heard back from him so I assume the scrapping went well.

I will look for the video.

Do you have enough wood? We are doing a job in Ledyard right now and will probably be leaving some wood behind. Where do you live? Do you have a truck? I have about 40 cord CSS with more on the ground in my yard. I'm only going to get the best wood and keep trying to figure a way to get 50 cord on my lot. I think I will only burn 10 cord a year now that the Oak, Maple & Locust are dry enough to add into the Poplar, Cherry & Ash.

If you would like to see my system I will point out what is good and what I wish I had done another way. I live in Hanover, 4 houses from Canterbury.

Maple1, I will look into the foam for tubing. I live on a gravel bank with very good drainage but if the outer pipe filled up it would take forever to empty / drain out.