Hi All -

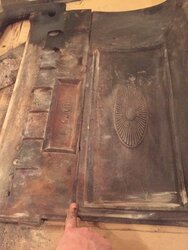

My Defiant II was on a pallet being moved to another location in my home. The pallet hit the ground abruptly and dislodged the upper fireback from the lower fireback and did not break or crack. As of right now, the upper fireback is wedged in pretty tight behind the lower fireback. I am assuming that I will need to break the stove down to get this back together. Does anyone have any other suggestions on fixing this?

My Defiant II was on a pallet being moved to another location in my home. The pallet hit the ground abruptly and dislodged the upper fireback from the lower fireback and did not break or crack. As of right now, the upper fireback is wedged in pretty tight behind the lower fireback. I am assuming that I will need to break the stove down to get this back together. Does anyone have any other suggestions on fixing this?

Don't tear it apart, you don't need to. All the interior parts are removable in th eD II. Just take out the lower baffle and continue from there. Not that bad, actually!

Don't tear it apart, you don't need to. All the interior parts are removable in th eD II. Just take out the lower baffle and continue from there. Not that bad, actually!