Maybe you read my recent post about my recent igniter failure that took out my control board.

That post is here:https://www.hearth.com/talk/threads...d-took-my-control-board-along-with-it.161418/

Anyhow, after getting a replacement board courtesy of the original manufacturer ( Applied Control Electronics - http://www.appconx.com/products/controlsystems.html )

I wanted to find out if I was able to repair my damaged board on my own. I am here to say that I was. It cost about $3 worth of parts.

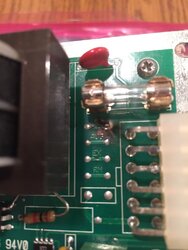

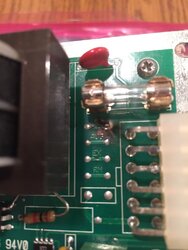

The first obvious failure was a blown trace on the printed circuit board. It was the trace that provided 120v line voltage to the igniter.

Here is that failure:

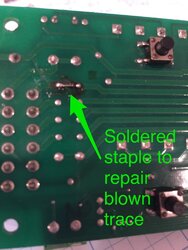

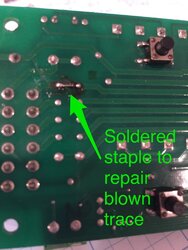

I was able to re-establish that connection on the other side of the board with a section of a wire staple that was cut to size and soldered to the existing pads.

Here is that repair:

Thinking that was only issue, I checked the repair and noticed (2) other failures after additional testing with an ohm meter and with the stove. The igniter triac had failed in the "ON" position. Essentially, line voltage was being sent to the igniter leads any time the stove was running, even after the stove got out of the start-up sequence.

I also noticed the same issue with the exhaust blower. That triac had also failed in the "ON" position. These (2) triacs were about $1.43 a piece on Newark.com. They are part T835-600G. I ordered 5 pcs and set about the repair. The old ones came off nice and easy with a basic 45W soldering iron. Nothing fancy. Not even any desoldering wick.

The replacements also went on with incident. It was kind of hard to get them straight, as you can see, but the finished product works great.

Now I've got a proper spare board that I can have at-the-ready in my parts bin. Although, considering I have wired up a SPST relay to handle turning the igniter on and also fused the igniter, I'm hopeful that I won't need the spare control board for a LONG time.

That post is here:https://www.hearth.com/talk/threads...d-took-my-control-board-along-with-it.161418/

Anyhow, after getting a replacement board courtesy of the original manufacturer ( Applied Control Electronics - http://www.appconx.com/products/controlsystems.html )

I wanted to find out if I was able to repair my damaged board on my own. I am here to say that I was. It cost about $3 worth of parts.

The first obvious failure was a blown trace on the printed circuit board. It was the trace that provided 120v line voltage to the igniter.

Here is that failure:

I was able to re-establish that connection on the other side of the board with a section of a wire staple that was cut to size and soldered to the existing pads.

Here is that repair:

Thinking that was only issue, I checked the repair and noticed (2) other failures after additional testing with an ohm meter and with the stove. The igniter triac had failed in the "ON" position. Essentially, line voltage was being sent to the igniter leads any time the stove was running, even after the stove got out of the start-up sequence.

I also noticed the same issue with the exhaust blower. That triac had also failed in the "ON" position. These (2) triacs were about $1.43 a piece on Newark.com. They are part T835-600G. I ordered 5 pcs and set about the repair. The old ones came off nice and easy with a basic 45W soldering iron. Nothing fancy. Not even any desoldering wick.

The replacements also went on with incident. It was kind of hard to get them straight, as you can see, but the finished product works great.

Now I've got a proper spare board that I can have at-the-ready in my parts bin. Although, considering I have wired up a SPST relay to handle turning the igniter on and also fused the igniter, I'm hopeful that I won't need the spare control board for a LONG time.