Hey guys,

It's warmed up, and I'm getting everything ready to do a little work on the chimney, but I had a few questions first.

I have a roughly 22' dual flue chimney with two 11x11" square terracotta flues that is installed on an exterior wall of a house. The chimney is on the exterior wall so that it sits outside the house footprint (surrounded by air on 3 sides). The fireplace is downstairs in a 2 story home (1600 sq. ft. downstairs and 1600 sq. ft upstairs)

I currently have installed a 6" SS liner insulated all the way up one of the flues with 1/2" insulation. Houzz (which has really good deals on insulation kits) sent me close to 10 extra feet of insulation.

For the remainder of last season (probably around February through April), I only had the flue that the liner was installed through capped at the top. The other flue and the damper were left open. I felt the stove held it's own though. It's a High Valley 2500 and would last all night keeping the downstairs at 72 and the upstairs around 69 throughout about 6-8 hours of the night (on roughly 30 deg nights) when loaded up. Dual cats in it worked well (thermometer verified temps of 1100-1400 deg).

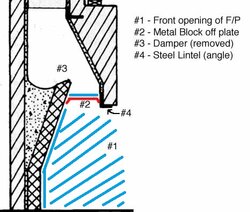

Obviously, I'm going to want to seal the flue the liner doesn't go down. But is this enough? I've kicked around the block off plate idea, but I'm not sure what kind of gains I could expect to see. Are we talking a 5% decrease in wood used or is it more like 30% increase? I felt like I saw the a ballpark number somewhere before, but I've searched for the past few days and found nothing.

My next question is about insulation. As I mentioned, I have some leftover insulation from my liner kit, and I'm thinking about using it on both the bottom-side of the flue seal plates and the top side of the damper plate (if necessary). I can't seem to find any r-value for this stuff though. Will it work well for this application or is Roxul the only way to go? How is it compared to Roxul insulation?

I really value you guys thoughts and comments. So please share what you're able.

Thanks in advance.

It's warmed up, and I'm getting everything ready to do a little work on the chimney, but I had a few questions first.

I have a roughly 22' dual flue chimney with two 11x11" square terracotta flues that is installed on an exterior wall of a house. The chimney is on the exterior wall so that it sits outside the house footprint (surrounded by air on 3 sides). The fireplace is downstairs in a 2 story home (1600 sq. ft. downstairs and 1600 sq. ft upstairs)

I currently have installed a 6" SS liner insulated all the way up one of the flues with 1/2" insulation. Houzz (which has really good deals on insulation kits) sent me close to 10 extra feet of insulation.

For the remainder of last season (probably around February through April), I only had the flue that the liner was installed through capped at the top. The other flue and the damper were left open. I felt the stove held it's own though. It's a High Valley 2500 and would last all night keeping the downstairs at 72 and the upstairs around 69 throughout about 6-8 hours of the night (on roughly 30 deg nights) when loaded up. Dual cats in it worked well (thermometer verified temps of 1100-1400 deg).

Obviously, I'm going to want to seal the flue the liner doesn't go down. But is this enough? I've kicked around the block off plate idea, but I'm not sure what kind of gains I could expect to see. Are we talking a 5% decrease in wood used or is it more like 30% increase? I felt like I saw the a ballpark number somewhere before, but I've searched for the past few days and found nothing.

My next question is about insulation. As I mentioned, I have some leftover insulation from my liner kit, and I'm thinking about using it on both the bottom-side of the flue seal plates and the top side of the damper plate (if necessary). I can't seem to find any r-value for this stuff though. Will it work well for this application or is Roxul the only way to go? How is it compared to Roxul insulation?

I really value you guys thoughts and comments. So please share what you're able.

Thanks in advance.