Hi everyone,

I posted this design plan rescently with some clearance questions for the stove pipe, and got some great answers. Thank You!

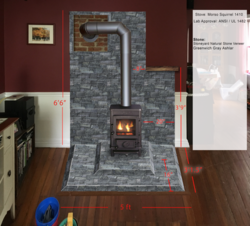

I'm just wondering, if I use 1/2" Micore 300 and 1/2" cement board under the natural cut stone veneer, Is the 1" ventilated air space necessary? Or required? (I'm in MA if that makes a difference).

Stove is a Morso Squirrel 1410 and has rear heat shield.

Does the vented air gap just apply to older stoves?

I can definitely build one, but I don't want to! It's going to put a 1" slit in my mantle, and I'll have an ugly 1" opening along the bottom. It will also create some challenging stone work below the chimney opening, since the vent will need to exhaust there too. I would also need to use 1" spacers between the Micore 300 and cement board, and I'm not sure if they would dig into the Micore over time. Is the Micore strong enough to hold the cement board away using 1/2 by 1" aluminum spacers if say, a child runs full speed into the veneer wall? Could happen I guess...

Anyway, just wondering if there's any way to fasten these layers together without the air space and all it's potential issues and design challenges.

And another thing - if dust accumulates over time in a ventilated air space... isn't that a fire hazzard?

So many questions - I appreciate the info!

Rob

I posted this design plan rescently with some clearance questions for the stove pipe, and got some great answers. Thank You!

I'm just wondering, if I use 1/2" Micore 300 and 1/2" cement board under the natural cut stone veneer, Is the 1" ventilated air space necessary? Or required? (I'm in MA if that makes a difference).

Stove is a Morso Squirrel 1410 and has rear heat shield.

Does the vented air gap just apply to older stoves?

I can definitely build one, but I don't want to! It's going to put a 1" slit in my mantle, and I'll have an ugly 1" opening along the bottom. It will also create some challenging stone work below the chimney opening, since the vent will need to exhaust there too. I would also need to use 1" spacers between the Micore 300 and cement board, and I'm not sure if they would dig into the Micore over time. Is the Micore strong enough to hold the cement board away using 1/2 by 1" aluminum spacers if say, a child runs full speed into the veneer wall? Could happen I guess...

Anyway, just wondering if there's any way to fasten these layers together without the air space and all it's potential issues and design challenges.

And another thing - if dust accumulates over time in a ventilated air space... isn't that a fire hazzard?

So many questions - I appreciate the info!

Rob