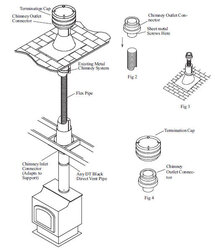

Will be installing an AGP, replacing a woodstove that is vented straight up into 6" Metalbestos chimney. I have a few questions about venting.

1) Is a connector required to go from the 3VP-TSB tee to the stove?

2) This is going to require an adjustable length of pellet pipe - 3VP-12adjB. How well do these adjustable lengths seal under the positive exhaust pressure? Is a bead of RTV recommended at the edge of the slip?

3) Any issues with the Selkirk adapter 3VP-A6 connecting to Metalbestos chimney? How does it securely attach to the chimney pipe?

1) Is a connector required to go from the 3VP-TSB tee to the stove?

2) This is going to require an adjustable length of pellet pipe - 3VP-12adjB. How well do these adjustable lengths seal under the positive exhaust pressure? Is a bead of RTV recommended at the edge of the slip?

3) Any issues with the Selkirk adapter 3VP-A6 connecting to Metalbestos chimney? How does it securely attach to the chimney pipe?