draft inducer

- Thread starter chuck172

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

hondaracer2oo4

Feeling the Heat

I don't believe it is safe to rely on any type of mechanical draft inducer on a wood burning appliance. What happens if the the power goes out or the fan fails?

maple1

Minister of Fire

Depending what you have - it might come in handy at fire lighting time.

Might also help in a marginal draft situation - but yes you would need to be cautious of what things would work like if it wasn't or stopped running when burning. Most, or many, of the good boilers have induction fans in them (so they are commonly relied on, so to speak).

(No direct experience here...)

Might also help in a marginal draft situation - but yes you would need to be cautious of what things would work like if it wasn't or stopped running when burning. Most, or many, of the good boilers have induction fans in them (so they are commonly relied on, so to speak).

(No direct experience here...)

I would only use the inducer for starting and adding to the fire. I wouldn't rely on it. I once did have my boilers fan stop (fuse) smoke entered the basement. If I had the inducer installed, I could have prevented the smoke situation.

hondaracer2oo4

Feeling the Heat

Sounds like a good idea than for starting fires. My Heatmaster g200 has a smoke bypass door with inducer fan. I get zero smoke out of the door. Works awesome.

goosegunner

Minister of Fire

Send me a pm with a email address and I will send you a video with my setup on a Econoburn. It is working extremely well.

Basically it is a high cfm blower used to create a Venturi. The blower is on a switched outlet. Also on the outlet is a electro magnet that holds the barometric damper closed while blower is running.

Basically it is a high cfm blower used to create a Venturi. The blower is on a switched outlet. Also on the outlet is a electro magnet that holds the barometric damper closed while blower is running.

heaterman

Minister of Fire

Sidewall venting you mean? That's a recipe for a disaster. Far as I know there is nothing on the market approved for wood.

The difference is with an oil or gas burner the fuel can be cut off instantly if the draft inducer fails or power is lost.

With wood, this is not possible.

The difference is with an oil or gas burner the fuel can be cut off instantly if the draft inducer fails or power is lost.

With wood, this is not possible.

maple1

Minister of Fire

heaterman

Minister of Fire

I have a masonry chimney with a neg draft. The only way to start a fire is to crack a basement window. It's just about impossible to add wood to an already started fire without smoke.

.

.

maple1

Minister of Fire

Sounds like some deeper issues that might need attention - and a condition that could be putting CO into your living space.

My boiler is natural draft, and an inducer fan was suggested at the outset as a possibility if I had trouble getting my draft going on a cold startup. But turned out to not be an issue. I have 30' of 7" SS insulated flu though. I also keep a basement window that's right behind my boiler slightly cracked open all winter, with a piece of FG insulation stuffed into the crack.

My boiler is natural draft, and an inducer fan was suggested at the outset as a possibility if I had trouble getting my draft going on a cold startup. But turned out to not be an issue. I have 30' of 7" SS insulated flu though. I also keep a basement window that's right behind my boiler slightly cracked open all winter, with a piece of FG insulation stuffed into the crack.

heaterman

Minister of Fire

jebatty

Minister of Fire

One of several brainstorm improvements to my Tarm was adding the automatic window opening to provide makeup air whenever the Tarm is operating. Makeup Air

maple1

Minister of Fire

I agree with Maple. Combustion air or makeup air is lacking.

We can't see the whole chimney either - have been assuming it is built/installed to specs etc. too. And if it is an uninsulated masonry chimney, that could compound - although that usually makes the draft hard to get going and maintain, & not make a downdraft per se. Then there are things like nearby trees or whatever, and the combo of prevailing winds & different roof lines that can sometimes do weird things to draft also. First thing I would check out is the outdoors height & roof relationship - without knowing anything about it.

An inducer might still be something to consider, but I don't think they are intended to correct a negative draft issue. Especially since it was said it is negative even with an already started fire - or, perhaps that wasn't quite worded right. I think even with a proper chimney draft in action, it is still quite possible and maybe even very likely to get some spillage out the door when the door is opened in certain fire conditions.

When starting a fire, I'll have neg. draft. If I crack open a basement window the draft turns positive. I do have a manometer installed. When the fire is going I'll have a pos. draft, but will get some spillage if I add wood. I'm refering to neg as downdraft..

I thought an inducer was intended to correct a neg. draft issue.

I thought an inducer was intended to correct a neg. draft issue.

maple1

Minister of Fire

My understanding is they are to improve an insufficient draft - not really to correct a negative. But I might be off on that understanding. I could see why though - if the power goes out or the fan quits for some reason, then your draft goes negative and you have CO entering the house. A very bad thing in the middle of the night. Or any time really. Seeing your draft go from - to + when a window is cracked seems to point to a makeup air issue, or too much outward ventilation from somewhere else - like an unbalanced ventilation system or exhaust fans running that don't have to.

Bad LP

Minister of Fire

My System 2000 LP boiler already had a fresh air supply into the airbox and vented to the chimney.

For my Tarm I will be cutting into that supply and adding a 24VDC powered damper that will open when the wood boiler is in operation. It will only drop air near the boiler and will not be directly piped to it. It's first fire in May after install didn't produce any issues but I had to repipe the LP boiler anyway so it was already disassembled.

For my Tarm I will be cutting into that supply and adding a 24VDC powered damper that will open when the wood boiler is in operation. It will only drop air near the boiler and will not be directly piped to it. It's first fire in May after install didn't produce any issues but I had to repipe the LP boiler anyway so it was already disassembled.

Ya even with .07 inches of water column with my blaze king princess 6" chimney it's almost impossible to do a reload mid burn to "top it off" with out letting smoke out. The 6" chimney even with a lot of draft just doesn't create enough velocity to be able to keep all the smoke in the stove. I know the main reason for these smaller diameter chimneys are to run more efficient and keep the chimney temp up (even as little as it is now 250-300) but they suck at reloads

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Indianadave

New Member

Something used on later steam locomotives with short smoke stacks, was called a blower. It simply was a steam line which was vented directly up into the stack which created the venturi effect to increase draught.

A friend was having smoke issues when firing up his forge. I suggested introducing a small air line into the double wall chimney for the same effect. It works really well as, is doesn't take much air to induce a draught. He used a small compressor with a ball valve in line to adjust the flow. It just has to be introduced into the last vertical section of the chimney somewhere.

A friend was having smoke issues when firing up his forge. I suggested introducing a small air line into the double wall chimney for the same effect. It works really well as, is doesn't take much air to induce a draught. He used a small compressor with a ball valve in line to adjust the flow. It just has to be introduced into the last vertical section of the chimney somewhere.

Indianadave

New Member

I guess I didn't mean the VERY last SECTION of vertical chimney pipe. Just somewhere in the vertical part of the chimney.

HappyHome

Member

Hello.

I have had several problems with smoke escaping into the roomduring startup and loading. I’d like to seeyour draft inducer setup qs well, if you don’t mind.

I have an econoburn 100, that i’m still figuring out.

I have had several problems with smoke escaping into the roomduring startup and loading. I’d like to seeyour draft inducer setup qs well, if you don’t mind.

I have an econoburn 100, that i’m still figuring out.

Send me a pm with a email address and I will send you a video with my setup on a Econoburn. It is working extremely well.

Basically it is a high cfm blower used to create a Venturi. The blower is on a switched outlet. Also on the outlet is a electro magnet that holds the barometric damper closed while blower is running.

goosegunner

Minister of Fire

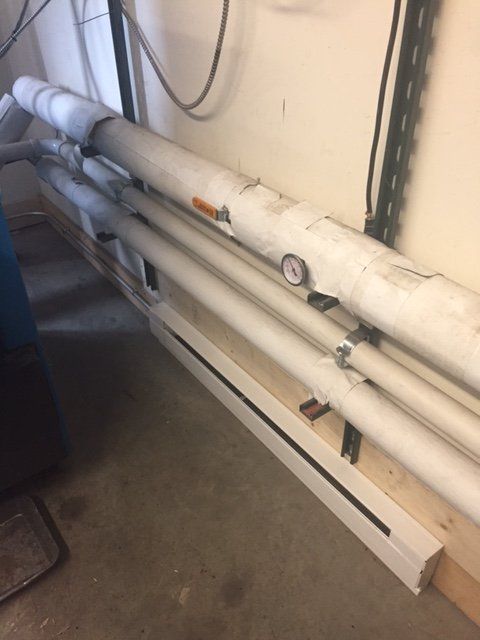

Here are some pictures. I have since sold the Econoburn and am now running a Froling S3 which is simply amazing!!.

The Exhaust pipe extended up the inside of the flue through the bottom of a T to maybe 8" past the flue outlet of the boiler.

The blower was on a switched outlet along with a electro magnet that would keep the barometric damper closed when the switch was on and the blower was running.

****IMPORTANT POINT*** The blower was only used when lighting or reloading the boiler. I virtually eliminated the smoke escape during those times. I have a good video but it is too large to load here.

The Exhaust pipe extended up the inside of the flue through the bottom of a T to maybe 8" past the flue outlet of the boiler.

The blower was on a switched outlet along with a electro magnet that would keep the barometric damper closed when the switch was on and the blower was running.

****IMPORTANT POINT*** The blower was only used when lighting or reloading the boiler. I virtually eliminated the smoke escape during those times. I have a good video but it is too large to load here.

NP ALASKA

Burning Hunk

Try changing your chimney cap. We changed ours to a directional cap that spins with the wind. You can find them on the internet. The lack of pressure at the end of the pipe inceeased velocity and we now have been loading the BK Princess with no more smoke issues.Ya even with .07 inches of water column with my blaze king princess 6" chimney it's almost impossible to do a reload mid burn to "top it off" with out letting smoke out. The 6" chimney even with a lot of draft just doesn't create enough velocity to be able to keep all the smoke in the stove. I know the main reason for these smaller diameter chimneys are to run more efficient and keep the chimney temp up (even as little as it is now 250-300) but they suck at reloads

Sent from my iPhone using Tapatalk

Just a thought

NP ALASKA

Burning Hunk

Try changing your chimney cap. We changed ours to a directional cap that spins with the wind. You can find them on the internet. The lack of pressure at the end of the pipe inceeased velocity and we now have been loading the BK Princess with no more smoke issues.

Just a thought

http://www.firewood-for-life.com/chimney-cowl.html

Like this

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 34

- Views

- 2K

- Replies

- 16

- Views

- 2K

- Replies

- 2

- Views

- 404