Most times, what is blamed on the stove, is not the stove's fault. You may find unless you fix the cause(s) of the issue, no matter what you throw in there will have the same issues. You're throwing a lot of cash at a problem you're not sure of the cause of. Too much heat is a matter of loading smaller loads or larger pcs., just not to the gills. I have had plenty of smaller loads burnt without any problems, many do it here. Same coffee can of nice brown fluffy cleanings every year.

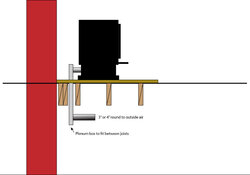

You don't have to go down to hook up an OAK, there are other options.

There is a the rare occurrence the issue may be the stove itself, but the percentages are very low.

I think you've jumped the gun, without finding out the cause to the symptoms.

You've also contradicted yourself stating you want to do it right, yet chose to forgo the insulation and go the cheapest, easiest route.

Cheapest, easiest is one theory that is not the best when dealing with wood burning appliances, especially if you're worried about the next owner suffering a burned down home. If that's the case, pull the stove and close everything off. Done deal