I really believe that my Taco 4900 is not working properly. I am thinking I should just replace the darn thing with a Spirovent or Caleffi.

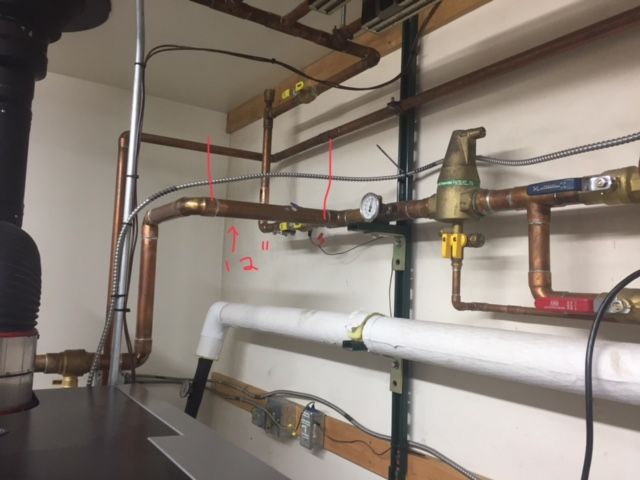

Here are some pictures of the current set up and measurements.

With my current set up it will be difficult to get it in the same spot as the Taco. I am thinking about moving it to a new spot which is also upstream from the circulator in a 12" section of straight pipe.

This is the new location I am considering. Will it be too close to the 90 on left and T on right?

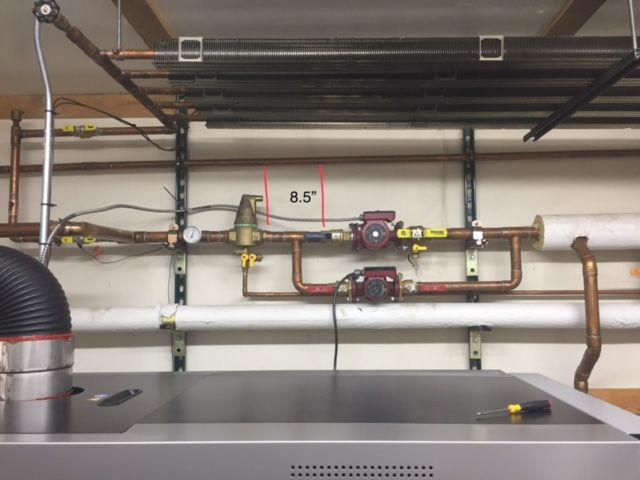

I have 1-1/2" pipe is this 8.5 inches too short between the air sep and start of pump flange valve?

Here are some pictures of the current set up and measurements.

With my current set up it will be difficult to get it in the same spot as the Taco. I am thinking about moving it to a new spot which is also upstream from the circulator in a 12" section of straight pipe.

This is the new location I am considering. Will it be too close to the 90 on left and T on right?

I have 1-1/2" pipe is this 8.5 inches too short between the air sep and start of pump flange valve?