Hello, I'm new to the forum and looking for some advice. I have a central boiler 5036 that I want to heat my new shop with. I already have oxygen barrier pex in the concrete. I want to make it a closed system so I won't have issues with build-up in the in floor pex. I know I need a plate exchanger, mixing valve, pumps, and manifolds. My question is how exactly to plumb it so it works correctly, or any other required components. Does anyone have any insight? I have done hours of research, but can't really find what I need. Thanks in advance for any help.

Closed system in floor

- Thread starter Freeheat83

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Buzz Saw

Minister of Fire

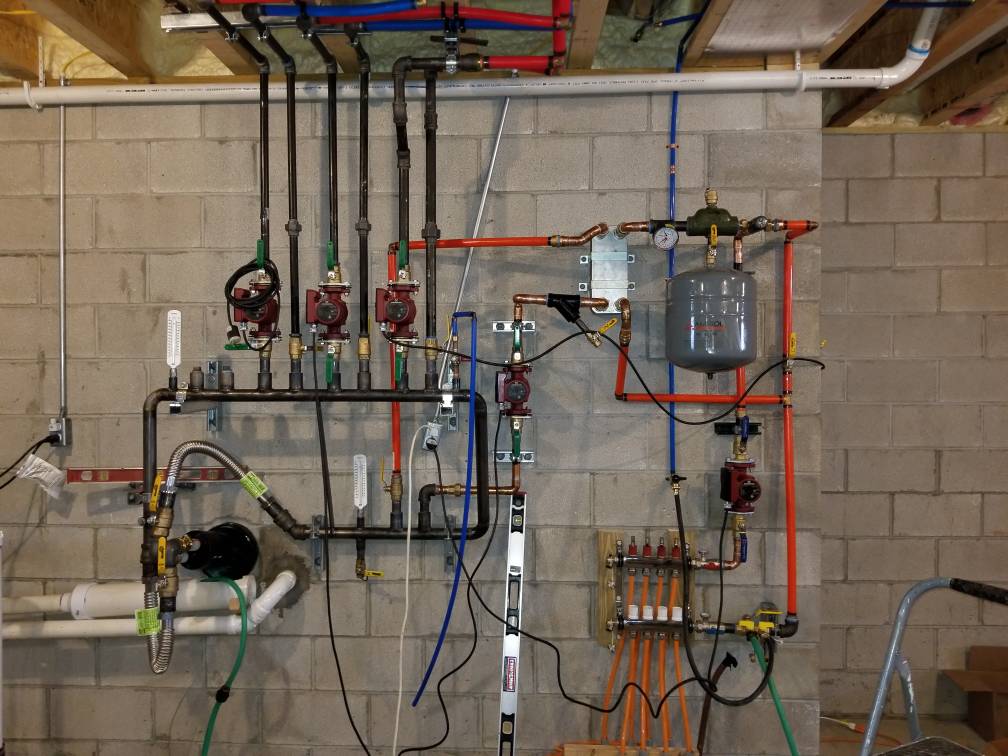

Just finished my basement floor a couple days ago. Everything to the right is in the closed floor system.

Get a flush valve, it's worth the slight difference in money compared to building your own.

Sent from my SM-G950U using Tapatalk

Get a flush valve, it's worth the slight difference in money compared to building your own.

Sent from my SM-G950U using Tapatalk

Thanks for the picture. Looks like a nice set up. I may be more ignorant to this than I thought. Haha What is the flush valve? Where is your mixing valve at, above the expansion tank?

Last edited:

Buzz Saw

Minister of Fire

Mixing valve is to the right of the air scoop(the thing above the tank). It's a manual mix valve. Twist the knob to set the temp. I'm going to control the pumps with an in floor thermocouple & controller. Don't ask what controller because I have no clue at the moment. [emoji848]I may be more ignorant to this than I thought. Haha What is the flush valve? Where is your mixing valve at, above the expansion tank?

Sent from my SM-G950U using Tapatalk

Ok. Sorry for so many questions. I just want to make sure I have it set up properly the first time. I've read that a four way mixing valve should be used to lessen the shock on the boiler from return water. Since the floor will be a closed system, there is no need for a four way, correct?

Buzz Saw

Minister of Fire

Purge valve, Not flush valve ♂️

https://www.supplyhouse.com/Webstone-48613-3-4-IPS-Purge-Fill-Full-Port-Forged-Brass-Ball-Valve

Supply house is great, but shop around because sometimes they are was out of line.

Buy your pumps off of EBay. Best prices in the net for a Grundfos UPS 15-58FC

Sent from my SM-G950U using Tapatalk

https://www.supplyhouse.com/Webstone-48613-3-4-IPS-Purge-Fill-Full-Port-Forged-Brass-Ball-Valve

Supply house is great, but shop around because sometimes they are was out of line.

Buy your pumps off of EBay. Best prices in the net for a Grundfos UPS 15-58FC

Sent from my SM-G950U using Tapatalk

Buzz Saw

Minister of Fire

I don't think you can shock a plate HX. Once the floor is up to temp very little water will pass through the plate, in my experience.Ok. Sorry for so many questions. I just want to make sure I have it set up properly the first time. I've read that a four way mixing valve should be used to lessen the shock on the boiler from return water. Since the floor will be a closed system, there is no need for a four way, correct?

Sent from my SM-G950U using Tapatalk

When sizing the exchanger, it is just sized by the required btu for my square footage? I have roughly 1100 SF. I found one online calculator that said it only required like 38,000 btu, which seemed low to me. Is there any downfall to an oversized exchanger? I can't think of any negative effects.

S.Whiplash

Member

- Oct 28, 2012

- 113

When sizing the exchanger, it is just sized by the required btu for my square footage? I have roughly 1100 SF. I found one online calculator that said it only required like 38,000 btu, which seemed low to me. Is there any downfall to an oversized exchanger? I can't think of any negative effects.

You're better off matching the flat-plate to your boiler output, not your floor requirements. In my experience oversizing a heat exchanger is never a bad thing.

jebatty

Minister of Fire

A neat thing you can do on the in-floor is determine how many btus are actually being absorbed by the floor. I see you have the flow valves on your pex zone manifold. If you then put a temp sensor on the supply and return to the floor you can calculate btus. Total floor gpm flow x 500 x  T will give you the btus. On my system, total flow is 2.25 gpm and

T will give you the btus. On my system, total flow is 2.25 gpm and  T typically is about 30F. Btus are 37,500.

T typically is about 30F. Btus are 37,500.

T will give you the btus. On my system, total flow is 2.25 gpm and

T will give you the btus. On my system, total flow is 2.25 gpm and  T typically is about 30F. Btus are 37,500.

T typically is about 30F. Btus are 37,500.Thanks for the info everyone. Whiplash, I figured it would be a safe bet to have a larger plate exchanger, than under sized, since the floor is the actual exchanger for heating. My thought was as long as the plate exchanger is efficient enough to supply the demanded btu's of the floor, it would not matter if it was over sized because the floor is the actual load.(hopefully that makes sense how I explained it).

Jbatty, that's a neat formula. I'll have to check it out once it's up and running.

I'm anxious to have it working.

Jbatty, that's a neat formula. I'll have to check it out once it's up and running.

I'm anxious to have it working.

3fordasho

Minister of Fire

Just finished my basement floor a couple days ago. Everything to the right is in the closed floor system.

Get a flush valve, it's worth the slight difference in money compared to building your own.

View attachment 220867

Sent from my SM-G950U using Tapatalk

Curious about your black pipe manifold, did you construct that yourself? Looks custom built with butt weld fittings?

maple1

Minister of Fire

Any brands of plate exchangers to avoid?

There may be & likely is - since there is a huge variation in prices in what I could find on line, one source to the next. But I don't really know. I got a B&G one through the local supplier that was reasonably priced - and B&G is a decent name. Although not sure if they outsource to places of questionable quality or not.

Buzz Saw

Minister of Fire

Yes, I custom built the manifold. I actually started a thread about building a manifold this past fall. I haven't had time to update it with the build pictures, but plan on it soon.Curious about your black pipe manifold, did you construct that yourself? Looks custom built with butt weld fittings?

Maybe I can get some stuff uploaded tonight.

Sent from my SM-G950U using Tapatalk

Karl_northwind

Minister of Fire

on plate HX, use flatplateselect.com to do your calculations, and then make sure your plate HX you are using has the same surface area in the same size class. not all 5x12 x 30 plate heat exchangers are created equal. I have seen two side by side that were 8.5 Square feet area and 13 both in a 5x12x30 plate.

if you are working off 160-180 f water, for 1100 sf you can get by with a 3x8x20 plate probably. your recovery time will be a little slow but it'll move 38000 btu with no problem given the delta T you have (180 to 110 approach temps)

if you are working off 160-180 f water, for 1100 sf you can get by with a 3x8x20 plate probably. your recovery time will be a little slow but it'll move 38000 btu with no problem given the delta T you have (180 to 110 approach temps)

Dutchie84

Member

Yes, I custom built the manifold. I actually started a thread about building a manifold this past fall. I haven't had time to update it with the build pictures, but plan on it soon.

Maybe I can get some stuff uploaded tonight.

Sent from my SM-G950U using Tapatalk

Buzz what did you use for the flex hose where your under ground is connected?

Buzz Saw

Minister of Fire

I used these. http://falconstainless.comBuzz what did you use for the flex hose where your under ground is connected?

I bought them from

https://www.plumbingsupply.com/flexes.html

One thing I found out is that even though the flex pipes are labeled at "full port" they are undersized. I had designed using there 1-1/4" lines but stepped up to 1-1/2". If I would have know that I would have put 1-1/2" threads on the manifold. It was a major pain in the butt having to size up after the fact with fittings. It really messed up how the flex lines were supposed to be routed.

It works though.

Sent from my SM-G950U using Tapatalk

Update.

I've got everything mounted, plumbed, and purged. Now I'm trying to find a line voltage thermostat, that will run my in-floor loop pump. It has only .5 amp draw. Everything I'm finding is not rated for inductive load, since they are intended for baseboard or cable in floor heat. Any suggestions?

I've got everything mounted, plumbed, and purged. Now I'm trying to find a line voltage thermostat, that will run my in-floor loop pump. It has only .5 amp draw. Everything I'm finding is not rated for inductive load, since they are intended for baseboard or cable in floor heat. Any suggestions?

festerw

Minister of Fire

I used a Taco switching relay in mine but there is this one.

https://www.grainger.com/product/DAYTON-Line-V-T-stat-1UHG4

https://www.grainger.com/product/DAYTON-Line-V-T-stat-1UHG4

Similar threads

- Replies

- 13

- Views

- 759

- Replies

- 40

- Views

- 3K

- Replies

- 5

- Views

- 726