When charging storage, the initial thought (in the beginning of gasser ownership) would be a one lap charge. That proved to be counter productive in my case. Excessive and conflicting on/off cycles of the blower and circulator proved to be less efficient. Two laps works quite well.

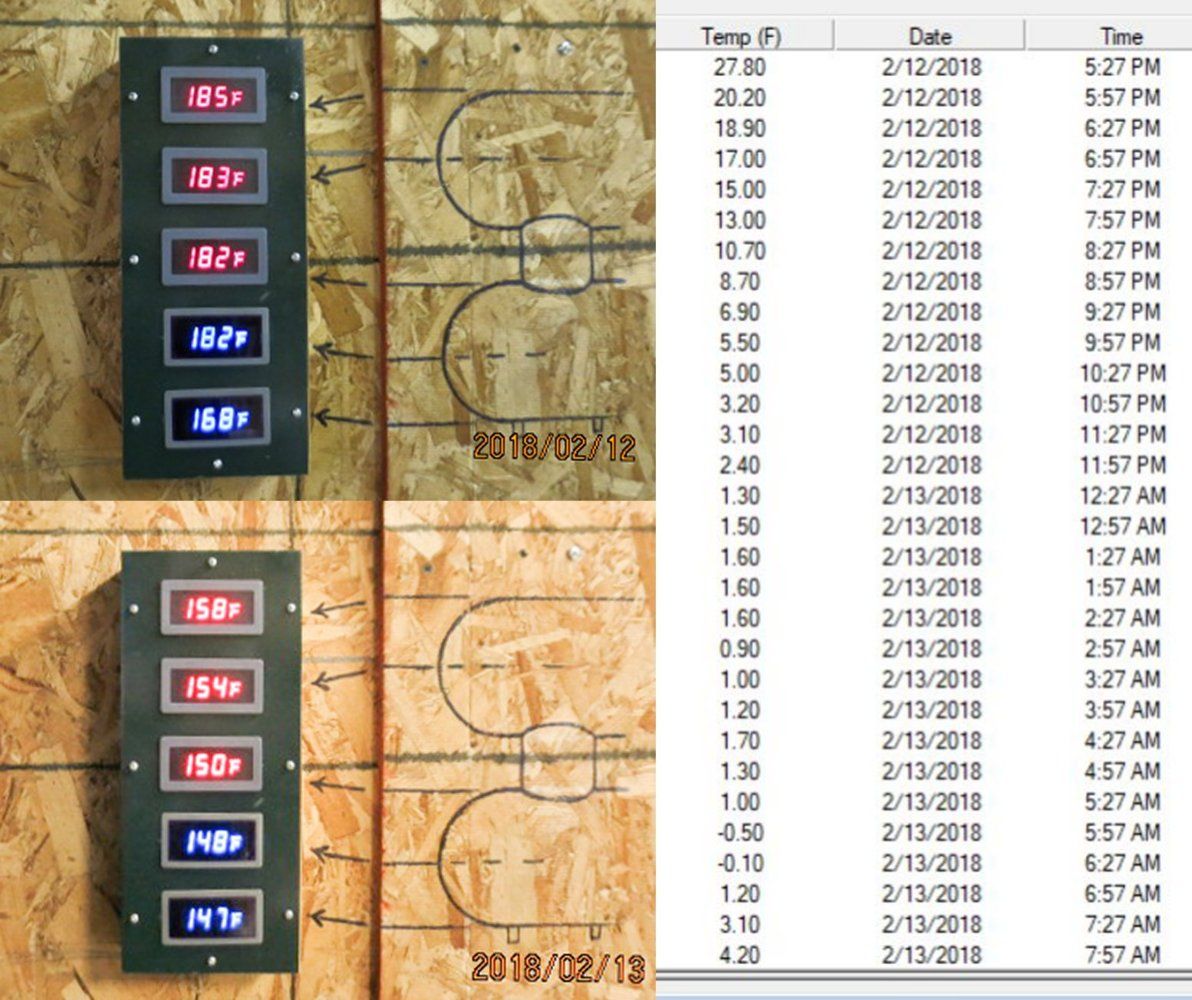

Drawing from storage demanded a one lap depletion, without ODR. With the use of ODR it now matches the charging strategy of a two lap rotation. As you can see from the following image and a little math, the total btu's used is right around a quarter million at the temps shown in a 14-1/2 hour period. For the Eko 25, a recharge of that amount is an easy ride. At double that, say a half million btu's, takes twice the time and attention to accomplish. Add the additional factor of bringing the boiler temp up to charging temps means for a 6 to 8 hour procedure which includes several reloads. So, I may rethink the charging theory again.

On the house side, ODR is giving favorable results. @Sparky The indoor feedback has so far been what I would expect. It shows best during the solar gains when it is closes the storage from the supply mix. On the other end, in frigid temps with strong winds, it did not keep up as well. What did work was to shift the reset ratio up for the cold snap. Immediately after installing the ODR control, I gave it a 1:1.4 curve from considering the house side of the system. After some trial and error, it is now at 1:1.43. During the cold stuff, 1:1.48 worked pretty good. Armatur doesn't include a decimal point on the LK 110 unit. A person could also bump the entire curve up by whatever degrees necessary to get the same result. Either way would require a reprogram when weather conditions level out.

Drawing from storage demanded a one lap depletion, without ODR. With the use of ODR it now matches the charging strategy of a two lap rotation. As you can see from the following image and a little math, the total btu's used is right around a quarter million at the temps shown in a 14-1/2 hour period. For the Eko 25, a recharge of that amount is an easy ride. At double that, say a half million btu's, takes twice the time and attention to accomplish. Add the additional factor of bringing the boiler temp up to charging temps means for a 6 to 8 hour procedure which includes several reloads. So, I may rethink the charging theory again.

On the house side, ODR is giving favorable results. @Sparky The indoor feedback has so far been what I would expect. It shows best during the solar gains when it is closes the storage from the supply mix. On the other end, in frigid temps with strong winds, it did not keep up as well. What did work was to shift the reset ratio up for the cold snap. Immediately after installing the ODR control, I gave it a 1:1.4 curve from considering the house side of the system. After some trial and error, it is now at 1:1.43. During the cold stuff, 1:1.48 worked pretty good. Armatur doesn't include a decimal point on the LK 110 unit. A person could also bump the entire curve up by whatever degrees necessary to get the same result. Either way would require a reprogram when weather conditions level out.

T. Do folks think I have that wrong? For

T. Do folks think I have that wrong? For