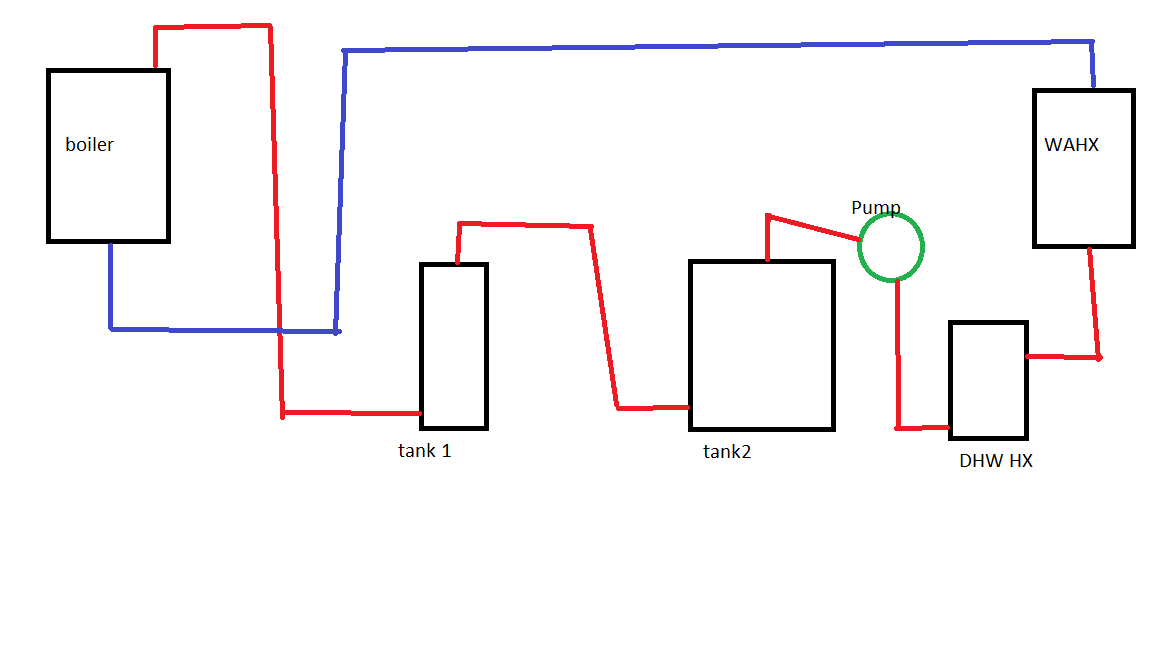

hey guys I am looking to improve my plumbing system and add in another tank to increase my water capacity, I will not be using heat exchangers between the boiler and tanks, I am basically trying to emulate a Garn only with the larger volume of water within the heated envelope. Here is a proposed layout courtesy of Warno, the plan would be to only run the boiler circ when firing, the house circ would need to run full time in order to make the DHW side arm function properly. Also bear in mind that the drawing does not include any isolation valves or anything of that nature. This is for my homemade boiler that is non pressurized with the air vent above the boiler. Thoughts on how this will function or if there is a better way? I am also including a drawing of the current layout. The notebook paper is the proposed layout and the paint drawing is the current

new plumbing layout

- Thread starter cumminstinkerer

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

maple1

Minister of Fire

Looks like drastic differences between the notebook one & the paint one. Are you sure about the paint version? That's all one big loop that would need to run all the time.

Not sure the function of the check valve in the first one - on quick look I'm not figuring out what it's to accomplish.

I think if you want to try to run this with everything unpressurized you'd maybe want your circulators down low on the returns.

Not sure the function of the check valve in the first one - on quick look I'm not figuring out what it's to accomplish.

I think if you want to try to run this with everything unpressurized you'd maybe want your circulators down low on the returns.

yes the original is all one big loop and runs continuous, that is what I am trying to get away from, the circs will be below the tank level and boiler is about six feet above the tanks, ;have to stay non pressure, I built the boiler and never planned on pressurizing, the tanks are also not capable of pressure. the check is to prevent back flow when only running the house pump.

maple1

Minister of Fire

No - the original (notebook?) is two loops. Boiler/tank loop, and tank/system loop.

Or am I mixed up on which one is which? You said paint was current so I was thinking the notebook was original.

Also don't think there would be any back flow when that house circ is running - the check is flowing the same way as the house circ. It's also flowing the same way as the boiler circ so don't see an effect there either.

Or am I mixed up on which one is which? You said paint was current so I was thinking the notebook was original.

Also don't think there would be any back flow when that house circ is running - the check is flowing the same way as the house circ. It's also flowing the same way as the boiler circ so don't see an effect there either.

Maple I maybe didnt make it clear, the paint drawing is how I currently have the system plumbed, the plan is to go to the notebook drawing.

maple1

Minister of Fire

Ok, I was mixed up.

Main thing (I think) when running non-pressurized is making sure the circs have enough inlet pressure. Cavitation & all that. So thinking the lower you can get them the better. So I would try to put them each on the lowest part of the system. Which sounds like the bottom of the tanks?

The other factor coming to me right now is what happens when you want to heat from tanks when the boiler isn't firing & that circ is stopped. You don't want the house circ to pull through the boiler when that is happening. There are some tactics to try to use to prevent it. The main simpler one but maybe hardest to get just right is plumbing it up so there is more resistance (head) to the house circ, from the boiler loop than the tank loop. So something simple like trying to put most of the T's & elbows needed on the boiler loop side vs. tank loop side. I.e., a straighter shot between the tanks and the house circ. One example of doing that a subtle way is moving your house circ feed from that T just right of the boiler circ, over to the right to a T that would come straight up out of tank 1 to your house circ. Similar at the bottom, turn the T around down there so coming from the house return is a straight shot into the tanks and the water coming from the tanks to the boiler has to take more turns.

Another step might be to move your house circ feed from that piping T just right of the boiler circ, to a separate fitting all together in the top of the tank. But that might complicate your piping - you would need separate runs for boiler & house piping to keep the reverse return thing happening. Something else that might help is to have the house circ running a fairly slow flow. Or better, something variable that you can tune flows with - like use an Alpha circ for your house so you can slow it down by throttling with one of your isolation valves. I know if I turn my house circ up faster, it will pull flow through the boiler. But won't otherwise.

Main thing (I think) when running non-pressurized is making sure the circs have enough inlet pressure. Cavitation & all that. So thinking the lower you can get them the better. So I would try to put them each on the lowest part of the system. Which sounds like the bottom of the tanks?

The other factor coming to me right now is what happens when you want to heat from tanks when the boiler isn't firing & that circ is stopped. You don't want the house circ to pull through the boiler when that is happening. There are some tactics to try to use to prevent it. The main simpler one but maybe hardest to get just right is plumbing it up so there is more resistance (head) to the house circ, from the boiler loop than the tank loop. So something simple like trying to put most of the T's & elbows needed on the boiler loop side vs. tank loop side. I.e., a straighter shot between the tanks and the house circ. One example of doing that a subtle way is moving your house circ feed from that T just right of the boiler circ, over to the right to a T that would come straight up out of tank 1 to your house circ. Similar at the bottom, turn the T around down there so coming from the house return is a straight shot into the tanks and the water coming from the tanks to the boiler has to take more turns.

Another step might be to move your house circ feed from that piping T just right of the boiler circ, to a separate fitting all together in the top of the tank. But that might complicate your piping - you would need separate runs for boiler & house piping to keep the reverse return thing happening. Something else that might help is to have the house circ running a fairly slow flow. Or better, something variable that you can tune flows with - like use an Alpha circ for your house so you can slow it down by throttling with one of your isolation valves. I know if I turn my house circ up faster, it will pull flow through the boiler. But won't otherwise.

thanks maple, that helps still trying to wrap my head around shutting the boiler loop down when not firing, my boiler is odd for sure and my draft control is in the garage with the boiler, easy enough there to run a wire but the bigger issue to me is how to get enough cold, relatively speaking, back to the boiler, the boiler does idle and will need to more than likely some as I am gone ten to eleven hours a day and the 700ish gallons of tanks wont probably be enough to last the whole day.

@maple1 I drew in the check valve in the return from home in the event the boiler was firing and the house was not calling for heat. That way the boiler would only charge the tanks with heat and not bypass any to the home. I'll have to talk with the OP again to see for sure what he wanted. I thought he was going to a batch burn set up similar to mine.

maple1

Minister of Fire

So circ vs circ, another thing to consider is that your boiler loop will likely need to flow more than your house loop. It will make a lot more heat when it's going, than your house loop would use (presumedly). So a healthy circ on the boiler side would help. I don't know what you have for circs and what the head losses are on each side, but IMO an Alpha on the house side and a 3 speed 15-58 on the boiler side is a decent match. Then, you can adjust boiler flow by the 3 pump speeds to get a decent dT thru the boiler, and vary house flow by switching up speeds on that circ along with throttling if needed. It could turn out to be quite a balancing act.

@warno I plan to batch as much as possible but may end up a little off on some days not sure yet. still curious about the amount return to the boiler to get it cool enough to call for fire unless just its radiant loss will be enough to lower it, or will I need to base may draft off tank temps now?

maple1

Minister of Fire

@maple1 I drew in the check valve in the return from home in the event the boiler was firing and the house was not calling for heat. That way the boiler would only charge the tanks with heat and not bypass any to the home. I'll have to talk with the OP again to see for sure what he wanted. I thought he was going to a batch burn set up similar to mine.

Unless I missed something I don't think that check there would prevent that situation?

It might be trickier to get everything balanced with the house circ running 24/7. If it was a start/stop system a zone valve would likely help. Mine is that type with zone valves.

maple1

Minister of Fire

@warno I plan to batch as much as possible but may end up a little off on some days not sure yet. still curious about the amount return to the boiler to get it cool enough to call for fire unless just its radiant loss will be enough to lower it, or will I need to base may draft off tank temps now?

With all that water in storage you should have lots of cool water for the boiler to draw from, with batch burning, long as you can get flows balanced out. Have you factored in return temp protection? Usually a key consideration with storage - you don't want return water lower than 140 entering the boiler.

maple1

Minister of Fire

maple1

Minister of Fire

Basically you don't want to have the house side interfering with the boiler side and vice versa. That should separate them just enough to prevent that while still maintaining reverse return for each.

maple1

Minister of Fire

@maple1 with your edit in the drawing won't the house return flow "slam", for lack of better term, into the boiler circuit return flow in that tee fitting at the bottom of tank 1? Maybe I'm thinking about it wrong but seems it might cause a fighting effect between the pumps.

I do agree too that a zone valve would work in place of the check valve but they are a bit more money than a simple swing check.

I do agree too that a zone valve would work in place of the check valve but they are a bit more money than a simple swing check.

maple1

Minister of Fire

I dont think? The only connection from house return to boiler return is thru the 3/4. Everything else would go thru the tanks. If both pumps are running the boiler circ should be pumping at higher flow than house circ assuming what I mentioned above. So most boiler return should be coming from tank bottoms. This is a bit out of my butt though, I am used to low intermittent load flows.

does anyone know why I couldn't use a 1000 gallon anhydrous ammonia tank, that has been evacuated for my storage?

maple1

Minister of Fire

As long as it has been vented and washed out you should be fine. Just fill it with water once and drain to get any heavy residue out. Then be sure to double check for any residual fumes before committing to add bongs and fittings. Not that it's flammable but the ammonia fumes can kill you if they over come you.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 0

- Views

- 940

- Replies

- 10

- Views

- 2K

- Replies

- 12

- Views

- 3K