After 15 years of heating with a older Lopi stove, we went ahead a purchased an Englander NC30 this past spring.

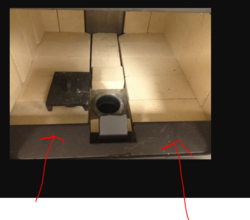

We have been using the stove for about a month now and have noticed that the metal plate right inside the door is warping. This is the plate (I don't know what to call it) that is flush with the door lip and is on either side of the device that shoots hot air into the firebox. We don't over-fire our stove, so I don't know why anything should be warping.

Has anyone else had this experience with the NC30?

We have been using the stove for about a month now and have noticed that the metal plate right inside the door is warping. This is the plate (I don't know what to call it) that is flush with the door lip and is on either side of the device that shoots hot air into the firebox. We don't over-fire our stove, so I don't know why anything should be warping.

Has anyone else had this experience with the NC30?