whats the secret to getting the hearthstone heritage to 500 deg? I've tried everything. My wood is oak dried to 8-14%. I can get it to 400 and a little bit but never near 500. Pipe is straight up with no bends and I dont think I have any kind of a draft problem.

taking hearthstone heritage to 500

- Thread starter Fred Bear

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

oh pretty high 25 30 feet. I measure the stove top with an IR and a stove top rutland thermometer. They both are pretty close to one another.

weatherguy

Minister of Fire

How are you measuring your moisture content? 8% seems real low, you measuring on a fresh split at room temp?

weatherguy

Minister of Fire

Are you splitting it then measuring on a fresh face? You cant just bring a split inside and measure it, it has to be resplit.measuring an old split at room temp with a harbor freight moisture meter

yes thats exactly what I did. I didnt know that. The wood is 2 years split. I'll slip some and measure

Highbeam

Minister of Fire

It takes forever to heat up a stone heritage. You will have to run at a high burn rate for hours and I would recommend also monitoring stove pipe temp to be sure you don’t overheat the chimney system.

I ran a heritage for about 30 cords. No problem getting it hot if your wood is dry, split small enough, loaded full, and you have lots of patience!

I ran a heritage for about 30 cords. No problem getting it hot if your wood is dry, split small enough, loaded full, and you have lots of patience!

orlkc

Member

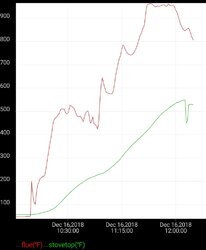

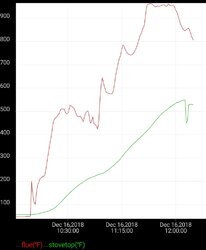

Here's my heritage going from cold start to above 500 dF stove top this morning. Started around 9:45 (late start today) with 4 small splits, some kindling, and a couple sheets of loose newspaper on top to get the draft started. Over the next hour I found that one of those splits was not as dry as the others and flue temps plateaued around 500 (not high enough for proper secondaries), but by then there was room to fill up more, so added four more splits, filling the firebox. The dip in stove top temperatures in the graph around 12:15 was where I moved the thermocouple probe further away from the flue collar to where it is in the photo.

Those flue temps are high. I suspect this may be Fred Bear's issue too. Highbeam reported this problem with his Heritage as well. It's odd because some people have normal flue temps with the Heritage. Just a guess but it seems like strong draft sends combustion up the flue instead of staying in the firebox.

should it be easy to get 500? would I benefit with a flue damper?Those flue temps are high. I suspect this may be Fred Bear's issue too. Highbeam reported this problem with his Heritage as well. It's odd because some people have normal flue temps with the Heritage. Just a guess but it seems like strong draft sends combustion up the flue instead of staying in the firebox.

Maybe. The first thing I would do is put a thermometer in or on the stove pipe to determine how much heat is being wasted. Is there single or double-wall stove pipe connecting the stove?

what would normal flue temps be? say at 350 or 400 stove topThose flue temps are high. I suspect this may be Fred Bear's issue too. Highbeam reported this problem with his Heritage as well. It's odd because some people have normal flue temps with the Heritage. Just a guess but it seems like strong draft sends combustion up the flue instead of staying in the firebox.

singleMaybe. The first thing I would do is put a thermometer in or on the stove pipe to determine how much heat is being wasted. Is there single or double-wall stove pipe connecting the stove?

OK, if single wall you can take the stove top thermometer and put it on the stovepipe about 18" above the stove for a burn cycle or two. If it is constantly >350-400º then yes, a flue damper may help.

Single wall, surface readings are approx half the flue gas temps inside the pipe. Ideally, with a non-cat stove, the flue gas temp will be about the same or 100º less than the stove top temperature once the air has been shut down and good secondary combustion is occurring.

PS: You are closing down the air once the wood is burning well, right?

PS: You are closing down the air once the wood is burning well, right?

right now the stove top is 348 and 18 inches up on the pipe is 275. I have an IR.OK, if single wall you can take the stove top thermometer and put it on the stovepipe about 18" above the stove for a burn cycle or two. If it is constantly >350-400º then yes, a flue damper may help.

Where is the air control set to and how long ago was the fire started?right now the stove top is 348 and 18 inches up on the pipe is 275. I have an IR.

fire started over 8 hrs ago and the air control is about 1/4 open . small fire today it's warm out.Where is the air control set to and how long ago was the fire started?

OK, that sounds fine for the late stage of a small fire. Track and report back with temps during a full load fire.

will doOK, that sounds fine for the late stage of a small fire. Track and report back with temps during a full load fire.

orlkc

Member

Thanks, I'll see about measuring the draft or adding a damper. In my case this is double walled pipe with the primary air setting at the stove all the way closed. What should I be looking for for internal flue temperatures? I've been reading lots of old threads, but most ended up discussing the variations between the bimetallic types. In more normal cases (stove less full) I see peak flue temps closer to 800 dF.Those flue temps are high. I suspect this may be Fred Bear's issue too. Highbeam reported this problem with his Heritage as well. It's odd because some people have normal flue temps with the Heritage. Just a guess but it seems like strong draft sends combustion up the flue instead of staying in the firebox.

The graph shows peaks in excess of 900ºF. This might just be that the air needs to be closed down much sooner or that the splits are too small or that the wood is super dry. Or a combination of these factors. Ideally you would be turning down the air with a probe flue temp of around 5-600ºF. This will vary with the stove, draft and fuel. On our stove I start turning down the air to about 50% at 400F probe temp and all the way down about 5-10 minutes after that. I try to avoid >800F flue temps.Thanks, I'll see about measuring the draft or adding a damper. In my case this is double walled pipe with the primary air setting at the stove all the way closed. What should I be looking for for internal flue temperatures? I've been reading lots of old threads, but most ended up discussing the variations between the bimetallic types. In more normal cases (stove less full) I see peak flue temps closer to 800 dF.

What system are you using for temperature monitoring and logging? Homebrew or off the shelf?

orlkc

Member

The only one of those that I can rule out is wood being too dry -- quite the opposite. Much is dry enough but a lot is still marginal. I'll need to wait another year until I can larger splits from stuff just stacked this year. I'm not re-splitting anything anymore unless I want a moisture reading. Getting the air completely turned down between 500 and 600 is indeed what seems to work without collapsing to a smoulder. I'll try some other variations such as the first step earlier. Perhaps I'll be able to turn down the air sooner when I have less marginal (20-25%) stuff in the mix.The graph shows peaks in excess of 900ºF. This might just be that the air needs to be closed down much sooner or that the splits are too small or that the wood is super dry. Or a combination of these factors. Ideally you would be turning down the air with a probe flue temp of around 5-600ºF. This will vary with the stove, draft and fuel. On our stove I start turning down the air to about 50% at 400F probe temp and all the way down about 5-10 minutes after that. I try to avoid >800F flue temps.

What system are you using for temperature monitoring and logging? Homebrew or off the shelf?

The other mistake from this particular example was reloading before the starting batch was down to just coals.

I've only had the monitoring and logging set up for a couple weeks, so I'm still getting used to acting on what it tells me. I didn't have a probe thermometer at all before that. It's an off the shelf tr-75wf -- hardest part was finding a Windows machine to do the initial configuration.

blacktop37

Member

Hello begreen, I have always run up to about 950 degrees my first morning fire flu temp with a probe, to try to clean out anything from the p.m. burn. Hearthstone Equinox. I'm not worried about chimney fire I have a stainless steel liner insulated inside a 12-inch tile masonry chimney. Do you think that that's too hot and I am causing problems with my liner? my chimney is cleaned by me once per year and it's looking great but I sure don't want to be harming my liner. I've had this stove setup for about 5 years. thank you for all your experienceThe graph shows peaks in excess of 900ºF. This might just be that the air needs to be closed down much sooner or that the splits are too small or that the wood is super dry. Or a combination of these factors. Ideally you would be turning down the air with a probe flue temp of around 5-600ºF. This will vary with the stove, draft and fuel. On our stove I start turning down the air to about 50% at 400F probe temp and all the way down about 5-10 minutes after that. I try to avoid >800F flue temps.

What system are you using for temperature monitoring and logging? Homebrew or off the shelf?

Similar threads

- Replies

- 0

- Views

- 300

- Replies

- 19

- Views

- 757

- Replies

- 12

- Views

- 2K