I've planning to do a heating rework at my house and I really want to tie it into my central HVAC phelum. I've had a thread going here where I started processing my options. I really think I've settled on a Vedolux 37 and storage; it was pretty much down to this or a Heatmaster G series. In the end I decided that over the long haul I really feel I'll burn less wood using the batch burning and storage style and not having the idle time when the system doesn't call for heat.

I am leaning towards putting it in my basement which limits my storage options. I'm still working on storage tank pricing and specs.

My current direction is the Vedolux V37 with 3 x 240 gallons ASME tanks. I've got a rough layout and I've got a few questions that I'm starting starting to get into on design.

I am leaning towards putting it in my basement which limits my storage options. I'm still working on storage tank pricing and specs.

My current direction is the Vedolux V37 with 3 x 240 gallons ASME tanks. I've got a rough layout and I've got a few questions that I'm starting starting to get into on design.

- First question is on pumps. It seems like the LK810 is pretty universally liked as a mixing valve going into the boiler. Do the boilers have no circulation pumps on their own? Or would this replace an internal one? Then that pump would only be in use while the boiler is running and I would need a second circulation pump after the tanks between the water to air heat exchanger in the phelum? That would be the circulator that would be called when the thermostat calls for heat?

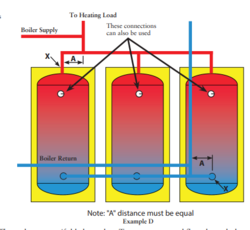

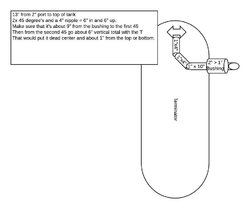

- Second is on the plumbing. I to use the 4 port tank model and run all of them in parallel one right into the other. I would have 1 1/4" coming into the first tank and probably 1" coming out of the last to the load. The biggest size I can do and keep everything uniform between the tanks is 1 1/2"; I figure go as large as I can there to promote water movement there? Or stick to something more uniform to the inlet or outlet?