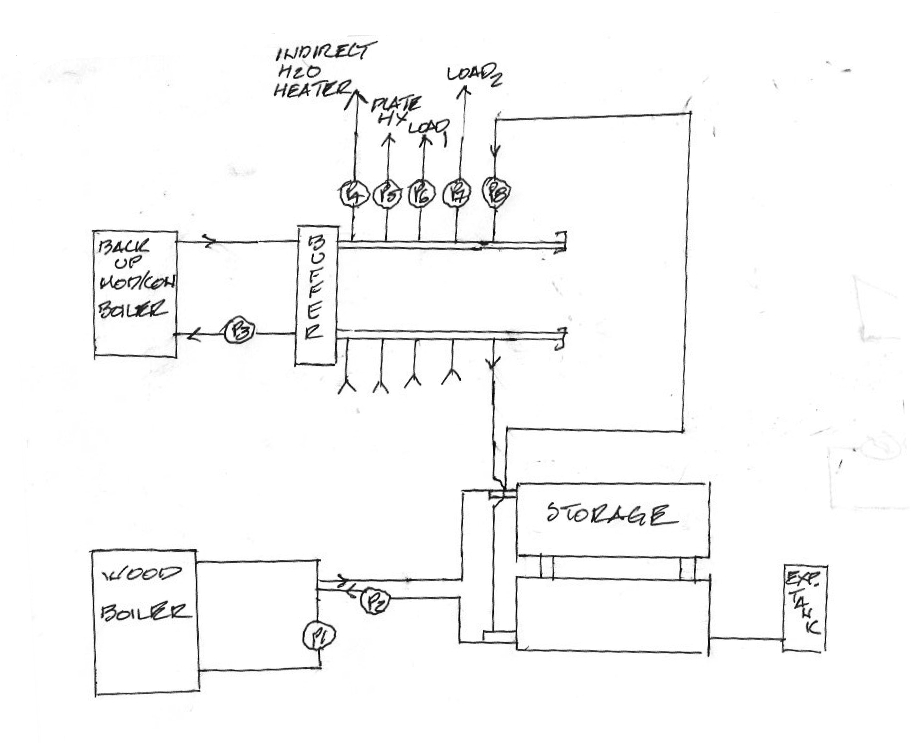

After many hours of research and contemplation, this is what I have come up with for my hydronic heating system design. Would appreciate any comments before I start the install...

A few details:

Wood boiler is a Econoburn 200 sending water from a dedicated woodshed outbuilding 30' underground to two stacked, 500 gal propane tanks in the basement of the house via a variable speed pump (190F water to storage and/or to the loads, return 80F-90F water from the bottom of storage, through 2" tank headers designed to maintain stratification.)

There is a propane back-up mod/con boiler on outdoor reset feeding a 100lb repurposed propane tank used as a buffer to limit short cycling. There are large supply and return headers from this buffer which service an indirect water heater (120 gal thermostore which is also plumbed to a heat pump hot water heater for summer use), a plate heat exchanger to cycle water through a Japanese ofuro (big bath tub), radiant in floor load 1 (basement), and radiant floor load 2 (1st floor). All radiant is in concrete slabs. Pumps for the loads are constant pressure, variable speed pumps feeding manifolds with actuator zone valves. There are 8 zones (2 in the basement and 6 on the first floor). The microzones necessitate the buffer tank on the mod/con boiler. The headers are also connected to storage, which feeds the loads through an outdoor reset controlled injection pump. This common header will allow the feeding of all loads from storage if temps there are available, else from the back-up boiler when they are not. Indirect heater load and plate HX loads will be priority ordered.

The zones are controlled with wifi enabled thermostats that will allow monitoring the temps remotely. Also plan to have a wifi enabled temp logging system to remotely monitor temps at roughly 8 points in the system.

This is the simplest configuration I could come up with given our needs. I thought about a tankless coil in the storage tanks and feeding the mod/con into storage to get rid of the buffer tank and indirect water tank but the storage tanks are a fair distance from the mod/con and I like the option to use the heat pump hot water heater in the summer as it also dehumidifies. I plan on a decent sized solar electric install in a year or 2 as well, which will run the heat pump hot water heater without wood or propane.

I have completed installation and rough plumbing of all the manifolds and would appreciate comments before I start the next phase of plumbing all the pumps. Thanks!

A few details:

Wood boiler is a Econoburn 200 sending water from a dedicated woodshed outbuilding 30' underground to two stacked, 500 gal propane tanks in the basement of the house via a variable speed pump (190F water to storage and/or to the loads, return 80F-90F water from the bottom of storage, through 2" tank headers designed to maintain stratification.)

There is a propane back-up mod/con boiler on outdoor reset feeding a 100lb repurposed propane tank used as a buffer to limit short cycling. There are large supply and return headers from this buffer which service an indirect water heater (120 gal thermostore which is also plumbed to a heat pump hot water heater for summer use), a plate heat exchanger to cycle water through a Japanese ofuro (big bath tub), radiant in floor load 1 (basement), and radiant floor load 2 (1st floor). All radiant is in concrete slabs. Pumps for the loads are constant pressure, variable speed pumps feeding manifolds with actuator zone valves. There are 8 zones (2 in the basement and 6 on the first floor). The microzones necessitate the buffer tank on the mod/con boiler. The headers are also connected to storage, which feeds the loads through an outdoor reset controlled injection pump. This common header will allow the feeding of all loads from storage if temps there are available, else from the back-up boiler when they are not. Indirect heater load and plate HX loads will be priority ordered.

The zones are controlled with wifi enabled thermostats that will allow monitoring the temps remotely. Also plan to have a wifi enabled temp logging system to remotely monitor temps at roughly 8 points in the system.

This is the simplest configuration I could come up with given our needs. I thought about a tankless coil in the storage tanks and feeding the mod/con into storage to get rid of the buffer tank and indirect water tank but the storage tanks are a fair distance from the mod/con and I like the option to use the heat pump hot water heater in the summer as it also dehumidifies. I plan on a decent sized solar electric install in a year or 2 as well, which will run the heat pump hot water heater without wood or propane.

I have completed installation and rough plumbing of all the manifolds and would appreciate comments before I start the next phase of plumbing all the pumps. Thanks!