Hey everybody... having a little issue with my 066 and looking for advice.

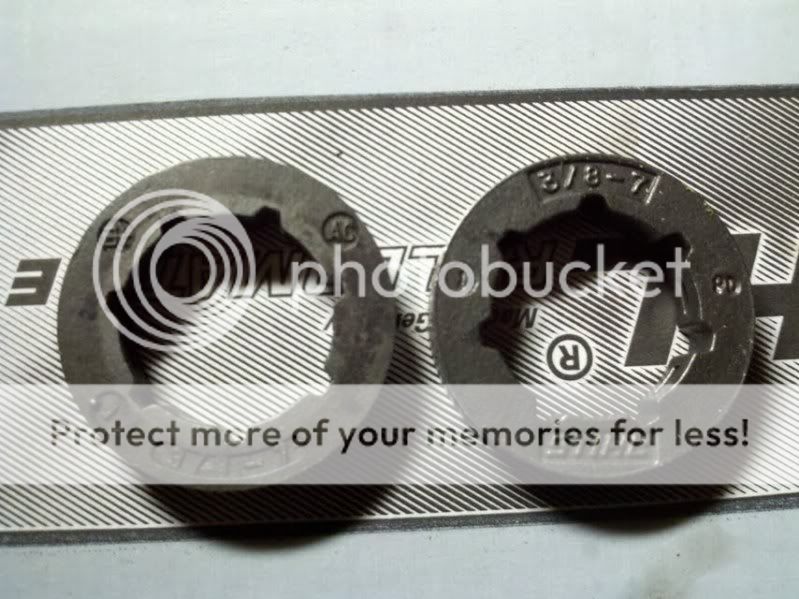

First question: Are there different sized bar nuts? I stupidly dropped one off the bench last night and stopped by the shop to pick another one up today. So, i had some trouble getting the replacement on. To be honest, i was in a bit of a hurry today (out to cut some scrounge) and just threw it on there. In hindsight, the bar nut wasn't on very tight and I think it's because the threads weren't matching up. As in, i put it on until i got resistance, but it wasn't on very tight. So, are there different sized bar nuts or is the bar "bolt" getting stripped?

So, this leads me to my 2nd question:

The chain tensioner broke, twice. The first time, i figured was my fault. Again, probably taking things for granted and over tightened last week. Couldn't get around to picking up a new one until today. I also picked up a replacement sprocket since the guy at the shop said it looked worn. Tension post broke like in the first picture below. So, replaced that piece of metal, also replaced the metal threaded bolt underneath since the one in there seemed a little bent/warped. Put both of those on and went cutting, along with my new bar nut that wasn't seeded right. Here's what happened:

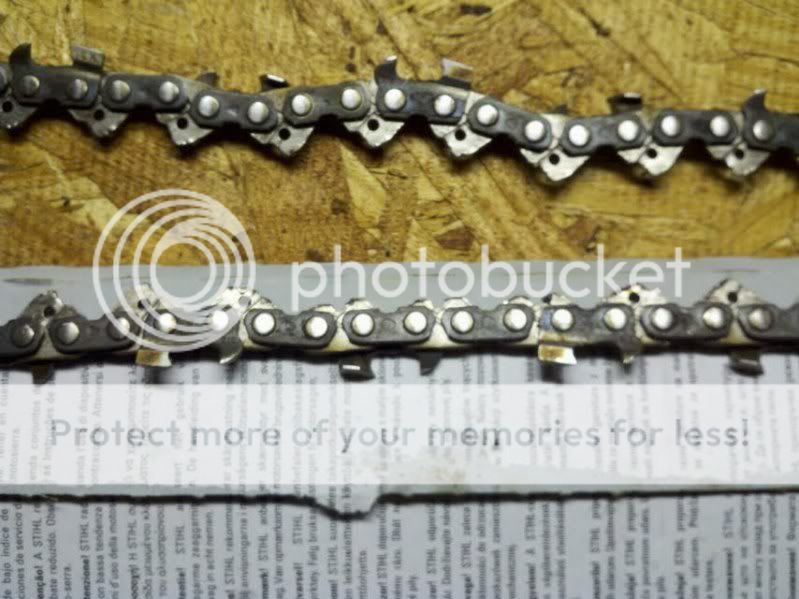

I was cutting for about 1/2 hr, everything going fine when all of a sudden the chain (newly sharpened, btw) jumped off the bar and bound while cutting. I think the chain and bar may be pretty screwed up... the chain is stuck in about 1/3-1/2 the bar and the under side of the chain looks chewed up. That may be due to the old worn sprocket it was running on but it's a pretty new chain.

So, here's what i found upon inspecting the saw: One of the bar nuts (the old one) had fallen off and the tensioner was broken AGAIN, same as first one. In addition, the newly purchased tension screw was broken (see 2nd pic).

Here are the rest of my questions (aside from whether i might have the wrong bar nuts. If it matters, the bar nuts thread VERY well on my 260 pro):

1) I can make the case that this is all related to using the wrong bar nut which didn't seat well and allow enough vibration for the other bar nut to come off which put a LOT of instability in the bar and broke the newly replaced tension parts.

2) Is there anything ELSE i should be worried about? As in, persistent breaking of tension apparatus is indicative of some other problem?

First question: Are there different sized bar nuts? I stupidly dropped one off the bench last night and stopped by the shop to pick another one up today. So, i had some trouble getting the replacement on. To be honest, i was in a bit of a hurry today (out to cut some scrounge) and just threw it on there. In hindsight, the bar nut wasn't on very tight and I think it's because the threads weren't matching up. As in, i put it on until i got resistance, but it wasn't on very tight. So, are there different sized bar nuts or is the bar "bolt" getting stripped?

So, this leads me to my 2nd question:

The chain tensioner broke, twice. The first time, i figured was my fault. Again, probably taking things for granted and over tightened last week. Couldn't get around to picking up a new one until today. I also picked up a replacement sprocket since the guy at the shop said it looked worn. Tension post broke like in the first picture below. So, replaced that piece of metal, also replaced the metal threaded bolt underneath since the one in there seemed a little bent/warped. Put both of those on and went cutting, along with my new bar nut that wasn't seeded right. Here's what happened:

I was cutting for about 1/2 hr, everything going fine when all of a sudden the chain (newly sharpened, btw) jumped off the bar and bound while cutting. I think the chain and bar may be pretty screwed up... the chain is stuck in about 1/3-1/2 the bar and the under side of the chain looks chewed up. That may be due to the old worn sprocket it was running on but it's a pretty new chain.

So, here's what i found upon inspecting the saw: One of the bar nuts (the old one) had fallen off and the tensioner was broken AGAIN, same as first one. In addition, the newly purchased tension screw was broken (see 2nd pic).

Here are the rest of my questions (aside from whether i might have the wrong bar nuts. If it matters, the bar nuts thread VERY well on my 260 pro):

1) I can make the case that this is all related to using the wrong bar nut which didn't seat well and allow enough vibration for the other bar nut to come off which put a LOT of instability in the bar and broke the newly replaced tension parts.

2) Is there anything ELSE i should be worried about? As in, persistent breaking of tension apparatus is indicative of some other problem?