Picked up a never used Wallenstein WX310 splitter. Would like to convert it to stand alone with a gas engine. The WX510 the company makes has a 5hp engine with 11gpm pump. Would a Harbourfreight 6.5hp with a 11gpm work the same? I want to also mount this on an axle that doubles as the oil tank.

3 point hitch conversion

- Thread starter pete1018

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

TreePointer

Minister of Fire

flewism

Member

Yes it would work just fine. I'm sure you realizes you also need filter. Are you going to fab up the tank axle assembly?

I will fab the axle. Tubing 3 inches wide by 6 in height with wheell spindles welded on. Took measurement off a splitter at TSC.

SolarAndWood

Minister of Fire

SolarAndWood

Minister of Fire

Most of the pumps you see for splitters will be rated at 2500 psi max 3000. For example, the Haldex 11 gpm pump is 11 at 650 and 2.9 at 2500 while the 16 is 16 at 650 and 3.5 at 2500. Both list max at 3K.

pete1018 said:Would 16gpm work? The cylinder has a sticker that says 2550 psi.

You have a problem. All of the engine driven two stage pumps appear to have a 3,000 PSI second stage. Everything downstream from that pump, including the hoses, should be able to handle at least 3,000 PSI. A 2,550 cylinder won't hack it. It's a basic safety issue.

However, that said, 2,550 is a bit of an odd rating for a cylinder. Generally, they are rated at multiples of 100, like 2,000, 2,500 or 3,000 PSI. But 2,550 PSI happens to be a common rating for tractor hydraulic pumps with engine at PTO speed. You might want to check with Wallenstein to find out exactly what that number indicates. It might actually be referring to the relief valve setting.

leaddog

Minister of Fire

He don't have a problem. Just set the relief valve to 2500 and every thing is good to go. If you don't have a relief valve most pumps will pump over the max setting and you can either blow the pump or kill the motor. If you dead head any hyd system something is going to give. You need a working relief valve and also a valve with an open center so you aren't pushing oil thru the relief when you don't need to. Oil heats up VERY fast when going over the relief so that is why the valve has an open center. oil just goes back to tank when not needed.WhitePine said:pete1018 said:Would 16gpm work? The cylinder has a sticker that says 2550 psi.

You have a problem. All of the engine driven two stage pumps appear to have a 3,000 PSI second stage. Everything downstream from that pump, including the hoses, should be able to handle at least 3,000 PSI. A 2,550 cylinder won't hack it. It's a basic safety issue.

However, that said, 2,550 is a bit of an odd rating for a cylinder. Generally, they are rated at multiples of 100, like 2,000, 2,500 or 3,000 PSI. But 2,550 PSI happens to be a common rating for tractor hydraulic pumps with engine at PTO speed. You might want to check with Wallenstein to find out exactly what that number indicates. It might actually be referring to the relief valve setting.

leaddog

Thanks for the info. I went to the companies site and the manual says it has a pressure releif valve factory set at 2550 psi at 3gpm.

Also states that a pressure guage should be installed on the inlet line if any adjustment is made. Would this mean I am ok and if so to what pressure should I adjust to or is this more trouble than its worth.

Also states that a pressure guage should be installed on the inlet line if any adjustment is made. Would this mean I am ok and if so to what pressure should I adjust to or is this more trouble than its worth.

Rigging a hydraulic system with a pump that puts out more pressure than one or more of the other components is rated for is always a problem. However, in this case the cylinder appears to be rated for at least 3,000 PSI, since the spec sheet provides a working force for that much pressure.

If you go ahead with this and leave the relief at 2,550, it is going to open fairly often, which isn't good. Each time the pump kicks into the high pressure mode, system pressure will build until either the log splits or the relief opens. With the relief set substantially below the maximum pressure of the pump, you will not enjoy as much splitting pressure as possible.

One of the most common log splitter valves out there is the Prince LS-3000. While its relief comes preset at 2,250 PSI, it can be adjusted to a maximum of 2,750 PSI. I would set the relief at that number. That way you will have 92% of the pump's maximum power available, instead of 85%. You should still have enough margin to prevent the pump from stalling the engine.

Just make sure that none of the hoses have been replaced with anything rated less than 3,000 PSI. If its never been used, that shouldn't be a problem.

If you go ahead with this and leave the relief at 2,550, it is going to open fairly often, which isn't good. Each time the pump kicks into the high pressure mode, system pressure will build until either the log splits or the relief opens. With the relief set substantially below the maximum pressure of the pump, you will not enjoy as much splitting pressure as possible.

One of the most common log splitter valves out there is the Prince LS-3000. While its relief comes preset at 2,250 PSI, it can be adjusted to a maximum of 2,750 PSI. I would set the relief at that number. That way you will have 92% of the pump's maximum power available, instead of 85%. You should still have enough margin to prevent the pump from stalling the engine.

Just make sure that none of the hoses have been replaced with anything rated less than 3,000 PSI. If its never been used, that shouldn't be a problem.

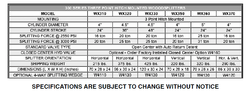

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 2K

- Replies

- 7

- Views

- 4K

- Replies

- 330

- Views

- 15K

- Replies

- 15

- Views

- 3K