Hi, first post and I wish I'd found this forum a few months ago.

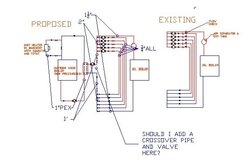

I've got a Crown Royal owb on the way and looking for advice on piping it into my existing boiler. Attached is a sketch showing my existing and proposed setup.

The heat exchanger is a something I salvaged from a gas conversion job, 2" bungs, 50 plate, but the tag is worn off. I would like to set it up as a primary/secondary loop but as I didn't pipe my original boiler that way this is how I would like to do it without redoing all the existing. Will it work? Thanks.

I've got a Crown Royal owb on the way and looking for advice on piping it into my existing boiler. Attached is a sketch showing my existing and proposed setup.

The heat exchanger is a something I salvaged from a gas conversion job, 2" bungs, 50 plate, but the tag is worn off. I would like to set it up as a primary/secondary loop but as I didn't pipe my original boiler that way this is how I would like to do it without redoing all the existing. Will it work? Thanks.