Alright guys just joined and I have a question regarding creosote buildup. I have just installed a UH-Max caddy (the green one) that I got off of Craigslist. Everything works as it should, I’ve got a static pressure of .24 on blower speed one. When I have a hot fire I’ve got a draft of .05 to 06 and when the damper is shut and fire is smoldering I’ve got a draft of roughy .03 to .025. Now here is my dilemma, I live in upstate New York (Syracuse area) and have an outside 7x7 clay flue chimney surrounded by CMU blocks. Local block company here sells the clay flue and CMU all one piece. Now does anyone here have a similar setup because I am worried that when the damper is shut and smoldering that I’m going to have a creosote factory in it. 2 story house chimney is about 3 foot above the peak roughy 25-30 foot high.

All EPA approved Wood furnace owners; I need your creosote Advice!

- Thread starter Davewoz123

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

brenndatomu

Minister of Fire

That doesnt sound good...when the firebox is up to temp and the damper closes, you should not have a smoldering fire...you should have nice secondary flames in the top of the firebox. If it doesn't do this I would say your wood may be wet...which that mixed with a too big masonry flue (49 sq inches vs 28 sq inches for a 6" round) will make for some creosote in the chimney for sure.when the damper is shut and fire is smoldering

Can you pull a 6" SS liner in? I think that low draft after the damper closes would improve a lot with a 6" flue...

Last edited:

my Wood might be a little wet, 15 cord of firewood cut in January and stacked in May. I’ve got a fan on it now in the basement where it’s next to my furnace where it’s hot and dry. I’ll check the moisture. But the manual calls for a 7” round flue with the wood oil combination and a 6” round flue for just the wood furnace. I’m thinking maybe a 6.5” liner might work. But I’m thinking with the damper completely shut I’m not going to get a good hot fire either way. I went and checked my flue temps yesterday after the damper was shut for a while and the top of my chimney flue was 70 degrees and it was nice and clean after 2 weeks of burning so far

brenndatomu

Minister of Fire

Yeah depending on the wood species and how/where it was stacked, it could be fine, to just OK, even flat out wet if it's something like Oak.my Wood might be a little wet, 15 cord of firewood cut in January and stacked in May

Having a fan on it in the basement will help bring things dry for sure...make sure to test the MC on a fresh split face (internal)

I guess I missed the part about it being a wood/oil Max Caddy. Not sure if anybody makes a 6.5" liner...I know they make 5.5". If your unit is supposed to have a 7", then the difference between 7" square and 7" round is not as great (38.5 vs 49) as if is supposed to run a 6", but the masonry still tends to run cool, (and you even said it was only 70*, it would ideally be over 212*F at the top) which kills draft, and makes creosote.

Gotta remember, draft is what makes the furnace work...and with low draft, the firebox doesn't get as hot, or burn as clean as it could otherwise...which equals dirty chimney sooner than would be otherwise. Good that it is still clean as of now though...keep checking it often until you find out what "normal" is gonna look like for you.

Might check with SBI, see if they will allow you to run a 6" liner (often times you can go up or down one size)...I think a 6.5" (if its made) will be very difficult to get into your 7" flue...there are often offsets and mortar joints that limit the actual ID to less that the nominal size.

Mostly burning ash this year, I’ll buy the harber freight one tomorrow so I will have a general idea. Now even with the damper completely closed you think the top of chimney should still be 212? That seems high where I doubt I’ll ever achieve that when the damper is closed especially on the single digit days.

Woodland sells this: https://www.woodlanddirect.com/Chimney/Bulk-Chimney-Liner/65in-Easy-Flex-Chimney-Liner

I’ll call the manufacturer tomorrow and see what they think even if I went with a 6” with a wood oil combination.

Woodland sells this: https://www.woodlanddirect.com/Chimney/Bulk-Chimney-Liner/65in-Easy-Flex-Chimney-Liner

I’ll call the manufacturer tomorrow and see what they think even if I went with a 6” with a wood oil combination.

brenndatomu

Minister of Fire

Well, considering that secondary burn doesn't even start until 1100* or so...and 12-1400* wouldn't be surprising at all to see in the firebox...yeah, I expect to see 212* at the top. That's another reason why it is important to have an insulated liner, reduced heat loss, so it stays cleaner. Also protects the structure from fire if needed too. Believe it or not, many (most) chimneys would not pass code inspection due to improper clearance to combustibles. (where it goes through, or attached to the structure...its surprising more houses haven't burnt down due to chimney issues)(mine wasn't built right, and this was considered a more upper end brick house here when it was built in '40)Now even with the damper completely closed you think the top of chimney should still be 212? That seems high where I doubt I’ll ever achieve that when the damper is closed especially on the single digit days.

Doesn't sound like you can get an insulated liner in there though...

brenndatomu

Minister of Fire

You have a good fire going there with the damper open...so all the flame is gone after a while when you close the damper?That’s my setup, a 4’ run to a 8” clay then it 90’s straight up to the top with the 7” square.

View attachment 251127

brenndatomu

Minister of Fire

I guess I don’t know much about the secondary burns obviously lol does the secondary burn happen in the firebox or in the baffles above the firebox? I did just switch wood to a pile that I had on a trailer that I was moving in and out of shelter all summer when it would rain and am getting a blue flame where the log is and the damper has been shut for a half hour

Mojappa

Burning Hunk

Secondary burn refers to the tubes at the top of the firebox that ignite the gasses above the fire

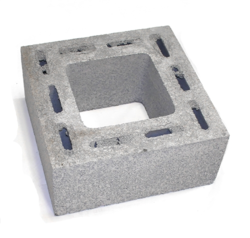

Is this your chimney block?

View attachment 251131

It’s like that but it has the clay tile in the middle. The supplier poured concrete around the clay flue in 24” sections.

If this video is correct with what secondary burns should look like then I think I am good. Here’s a video of mine after 40 min of damper being closed:

brenndatomu

Minister of Fire

In the firebox.does the secondary burn happen in the firebox or in the baffles above the firebox? I did just switch wood to a pile that I had on a trailer that I was moving in and out of shelter all summer when it would rain and am getting a blue flame where the log is and the damper has been shut for a half hour

Primary fire is the wood burning directly...like a camp fire.

Secondary burn happens after the wood and firebox is brought up to normal operating temps and then the primary air is cut back (damper closed) over a period of a few minutes, as things calm down in there, you will see the fire kinda move from the wood, to kinda floating over the wood, more so against the top of the firebox (baffle) where the 4 (more on a Max?) air tubes go across. Speaking of baffle, make sure it is in place properly from time to time. It may be out of place from moving, or can be bumped around when loading wood. It should be centered, laying flat on the air tubes, and slid clear against the back firebrick.

Anyways, when you see that secondary fire, that is the wood off gassing, and the gas/smoke is what's actually burning...that's a really hot fire too...and very efficient/clean. If that flame goes away, then the wood is often left smoldering.

I guess I should mention that the secondary fire usually only lasts the first couple hours of a load...after that the wood is more like red hot charcoal...the volatiles have been burnt off and the coals burn down pretty cleanly after that.

Mrpelletburner

Minister of Fire

brenndatomu

Minister of Fire

Yes, if that is your firebox after the damper has been shut for 40 minutes...looks good.

If this video is correct with what secondary burns should look like then I think I am good. Here’s a video of mine after 40 min of damper being closed:

View attachment 251135

I guess I got off track when I read "smoldering" in your first post...sorry!

brenndatomu

Minister of Fire

Mrpelletburner

Minister of Fire

Secondary burn

Wow that is wild, mine definitely isn’t that intense. Ill inspect the baffle tomorrow when everything cools down to make sure everything is in place, I bought it in Vermont and drove it back here, only paid $1,300 for it which included the Becker oil burner. Do the baffles ever have to be cleaned?

brenndatomu

Minister of Fire

Dude! You stole that thing!I bought it in Vermont and drove it back here, only paid $1,300 for it which included the Becker oil burner. Do the baffles ever have to be cleaned?

Baffle doesn't need cleaned, no. The heat exchanger tubes do though...I did my Tundra tubes about once per week...some people do it less...but I was shooting for max efficiency...and it is sooo stinkin easy to do on these furnaces!

That’s why I dropped everything I was doing drove out there haha I was about to pull the trigger on a $7k brand new one when this showed up Craigslist. Now my final question is I’m assuming no matter what I should open up the damper when I load the wood in? Cause there are some nights where I’m at 71* in the house, damper closed and about to go to bed with still a couple half burned logs on that wouldn’t last through the night but opening the damper makes the house shoot it 5 degrees in no time.

brenndatomu

Minister of Fire

That's where it takes some experience...and everybody's house is different.That’s why I dropped everything I was doing drove out there haha I was about to pull the trigger on a $7k brand new one when this showed up Craigslist. Now my final question is I’m assuming no matter what I should open up the damper when I load the wood in? Cause there are some nights where I’m at 71* in the house, damper closed and about to go to bed with still a couple half burned logs on that wouldn’t last through the night but opening the damper makes the house shoot it 5 degrees in no time.

Its all about load management...knowing when, how much, and what type of wood to load.

But yes, the damper must be opened long enough to bring the firebox up to temp to get it working properly/cleanly...these things are meant to be batch burners...not like a fireplace where you load a log or two on every once in a while.

Keep in mind that all wood contains 8600 BTU's per #...so if you load X number of lbs, all things being equal (tstat is satisfied, and the damper is closed the whole time after the intital opening) it will take X hours to burn down X lbs and provide X BTU's...if its dry pine, a whole firebox full might be 50 lbs...if its Oak then a whole load may be 100 lbs.

If you want a quick small fire, load in some low BTU wood, pine, poplar, soft maple, etc....to get a small load to burn right, stack it tall...I like "log cabin style".

And sometimes when the weather is up and down, its so much easier to run that oil burner for a bit...got to keep the goal in mind...ease the heat bill, and still have a life...so if the wood can cover 90% of your heating, I think most people would consider that a win. 100% of your heat from a wood furnace is a PITA...been there done that.

Totally understand, makes sense. House is pretty well insulated and when the damper is shut it can pretty keep the house at the current temp with outside temps in the mid 20s. Thanks for all the info! I’ll definitely make sure my fire is up to temp before the damper closes, that was definitely my problem for a couple of fires I had

Mrpelletburner

Minister of Fire

Cold start this morning, outside mid 30's F... The video was captured ~15-20 mins after starting, kept the door cracked open for the first 10mins.

JRHAWK9

Minister of Fire

Cold start this morning, outside mid 30's F... The video was captured ~15-20 mins after starting, kept the door cracked open for the first 10mins.

cool video. I don't know about the rest of you guys, but I sorta miss all those mini-explosion videos from the past.

Similar threads

- Replies

- 36

- Views

- 3K

- Replies

- 31

- Views

- 3K

- Replies

- 5

- Views

- 2K

- Replies

- 6

- Views

- 2K