Greetings!

I've been lurking for a while now, finally got off my butt and composed a few questions. Your opinions are appreciated.

For my pole barn workshop I have bought a Country Comfort CC175 off Craigslist. It's on the EPA list of certified wood stoves, and it meets Washington State Limits (barely).

Code requires that the stove be 18" off the floor if it's installed in a garage. Is the 18" measured from the bottom of the firebox or the pedestal attached to the stove?

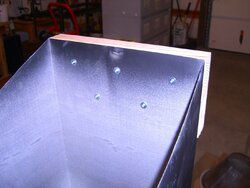

Any thoughts on the platform and heat shield? I'm thinking of cinder blocks with a metal sheet across them. I'd fill the blocks with sackrete (sp?) and make sure it's stable, but want to keep the cost to a minimum. Having a nice big thermal mass under the stove is part of the idea too (and it would be built to allow air flow under the platform).

As far as a heat shield, I'm thinking of a simple block wall filled with sackrete behind the stove. I'd build the wall 6 or 8" from the shop wall and put a couple of small wings on it. Crude diagram below

\_Stove_/

____________

Air could flow all the way around it, and it would provide a little residual heat so the shop doesn't cool off too much overnight.

I"m also going to mount a fan up in the trusses. I'll wire it in to the plugs the lights are on. Lights off = fan off. Thanks to whomever I read that little tid bit from!

Any other thoughts, ideas, suggestions, etc?

I've been lurking for a while now, finally got off my butt and composed a few questions. Your opinions are appreciated.

For my pole barn workshop I have bought a Country Comfort CC175 off Craigslist. It's on the EPA list of certified wood stoves, and it meets Washington State Limits (barely).

Code requires that the stove be 18" off the floor if it's installed in a garage. Is the 18" measured from the bottom of the firebox or the pedestal attached to the stove?

Any thoughts on the platform and heat shield? I'm thinking of cinder blocks with a metal sheet across them. I'd fill the blocks with sackrete (sp?) and make sure it's stable, but want to keep the cost to a minimum. Having a nice big thermal mass under the stove is part of the idea too (and it would be built to allow air flow under the platform).

As far as a heat shield, I'm thinking of a simple block wall filled with sackrete behind the stove. I'd build the wall 6 or 8" from the shop wall and put a couple of small wings on it. Crude diagram below

\_Stove_/

____________

Air could flow all the way around it, and it would provide a little residual heat so the shop doesn't cool off too much overnight.

I"m also going to mount a fan up in the trusses. I'll wire it in to the plugs the lights are on. Lights off = fan off. Thanks to whomever I read that little tid bit from!

Any other thoughts, ideas, suggestions, etc?