From what I understand the best place to put a circulating pump is after the expansion tank of course. The tank goes on the air scoop, that ends up on the boiler supply at the high point right, so the potential exists for that pump to see some high water temps. I also noticed, after having looked at a lot of diagrams on here that many people put the pump on the return line to the boiler, which is how my oil fired on is hooked up. This set up is a conventional wood boiler going to a storage tank and I certainly don't want to destroy pumps with high temps. I am putting an expansion tank on the air scoop so I can run without the storage if I choose to. So where is the best place for the pump?

Best place for circulator pump?

- Thread starter cheapsx

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

taxidermist

Minister of Fire

On return side right at the boiler. You can see some pics of my plumbing at my blog link at the bottom of this page.

Rob

Rob

Nofossil

Moderator Emeritus

Here's my understanding:

The reason for placing it after the expansion tank is that in that location it has the least chance of cavitating. If you're running a higher powered circulator you can get a pretty good pressure rise across the circulator. If you're pumping towards the expansion tank, then your circ inlet pressure will be significantly below your system pressure as maintained by the expansion tank. If you're also running higher water temps, you can have a situation where the circ inlet pressure is low enough to cause the water to flash to steam. This is BAD for circulators.

In most residential systems, the circualtors are small enough and the temperatures are low enough that this is not a problem. Many systems (including mine) are plumbed with the circ on the boiler inlet.

In the old days, mounting the circ on the boiler inlet was often done to enhance seal life by exposing the circ to lower temps. With modern seal materials this is much less of a concern.

If you can, it does make sense to mount your circs so that the pump upwards, though - makes clearing air bubbles much easier.

The reason for placing it after the expansion tank is that in that location it has the least chance of cavitating. If you're running a higher powered circulator you can get a pretty good pressure rise across the circulator. If you're pumping towards the expansion tank, then your circ inlet pressure will be significantly below your system pressure as maintained by the expansion tank. If you're also running higher water temps, you can have a situation where the circ inlet pressure is low enough to cause the water to flash to steam. This is BAD for circulators.

In most residential systems, the circualtors are small enough and the temperatures are low enough that this is not a problem. Many systems (including mine) are plumbed with the circ on the boiler inlet.

In the old days, mounting the circ on the boiler inlet was often done to enhance seal life by exposing the circ to lower temps. With modern seal materials this is much less of a concern.

If you can, it does make sense to mount your circs so that the pump upwards, though - makes clearing air bubbles much easier.

in hot water

New Member

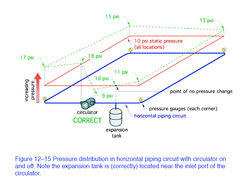

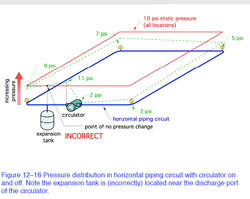

The pump should pump away from the PONPC, that being the expansion tank connection. circulators move water by lowering the pressure on the suction side, and raising it on the discharge. By pumping away from the expabsion tank the heating distribution side "sees" that pressure increase and aids in air removal throughout the system.

Not, that being said, modern boilers with small coil, restrictive heat exchangers, like mod con boilers, prefer to have the circ pumping into the boiler. This increases the pressure that the boiler HX sees and reduces the potential for flashing in the boiler. BUT... you need to move the expansion tank connection to where that pump is located. So technically you are still pumping away from the PONPC, even though you are pumping into the boiler return.

The air elimination device (purger) is still best at the highest temperture zone, that being at the boiler discharge.

So split the purger and expansion tank locations if you chose to pump into the boiler return. Pump into the boiler if you must, but tie the expansion tank into the system at the suction side of the circulator.

Keep in mind modern circulators are designed to operate at 225 °F . So pumping away from the boiler on the hot, supply side is not an issue.

Here is what this expansion tank concept looks like in a schematic. Used with permission Modern Hydronics 3rd edition, John Siegenthaler

Not, that being said, modern boilers with small coil, restrictive heat exchangers, like mod con boilers, prefer to have the circ pumping into the boiler. This increases the pressure that the boiler HX sees and reduces the potential for flashing in the boiler. BUT... you need to move the expansion tank connection to where that pump is located. So technically you are still pumping away from the PONPC, even though you are pumping into the boiler return.

The air elimination device (purger) is still best at the highest temperture zone, that being at the boiler discharge.

So split the purger and expansion tank locations if you chose to pump into the boiler return. Pump into the boiler if you must, but tie the expansion tank into the system at the suction side of the circulator.

Keep in mind modern circulators are designed to operate at 225 °F . So pumping away from the boiler on the hot, supply side is not an issue.

Here is what this expansion tank concept looks like in a schematic. Used with permission Modern Hydronics 3rd edition, John Siegenthaler

Attachments

I am a plumbing idiot..so keep that in mind. The contractor that built and plumbed my house had put the circulator (1 zone ranch at that time) on the return side of the boiler. Said 50% like the pump on the supply side and 50% like the pump on the return side. He was always taught return. Old school!

Recently he has been telling me I should move the pump to the supply side because industry has been finding that if you run a mixing valve between the supply and return and run 150 deg water through the baseboard, there is a significant cost savings. The boiler would still produce 180 deg water. To do this he said the pump has to be on the supply side.

Point is, prior to buying a gasser I planned on making this plumbing change. It may still be worth doing for the non gassifier transition month(s). Just wondering if anyone had heard of the benefit of mixing supply/return and running lower temps through the baseboard?

Recently he has been telling me I should move the pump to the supply side because industry has been finding that if you run a mixing valve between the supply and return and run 150 deg water through the baseboard, there is a significant cost savings. The boiler would still produce 180 deg water. To do this he said the pump has to be on the supply side.

Point is, prior to buying a gasser I planned on making this plumbing change. It may still be worth doing for the non gassifier transition month(s). Just wondering if anyone had heard of the benefit of mixing supply/return and running lower temps through the baseboard?

jimmie ray

New Member

in hot water said:The pump should pump away from the PONPC, that being the expansion tank connection. circulators move water by lowering the pressure on the suction side, and raising it on the discharge. By pumping away from the expabsion tank the heating distribution side "sees" that pressure increase and aids in air removal throughout the system.

Not, that being said, modern boilers with small coil, restrictive heat exchangers, like mod con boilers, prefer to have the circ pumping into the boiler. This increases the pressure that the boiler HX sees and reduces the potential for flashing in the boiler. BUT... you need to move the expansion tank connection to where that pump is located. So technically you are still pumping away from the PONPC, even though you are pumping into the boiler return.

The air elimination device (purger) is still best at the highest temperture zone, that being at the boiler discharge.

So split the purger and expansion tank locations if you chose to pump into the boiler return. Pump into the boiler if you must, but tie the expansion tank into the system at the suction side of the circulator.

Keep in mind modern circulators are designed to operate at 225 °F . So pumping away from the boiler on the hot, supply side is not an issue.

Here is what this expansion tank concept looks like in a schematic. Used with permission Modern Hydronics 3rd edition, John Siegenthaler

That's a very thorough explanation. It's funny how when most of the industry just started catching on to pumps on the supply side, mod-cons with high pressure drop heat exchangers and steam flashing issues were introduced...

in hot water

New Member

b33p3r said:I am a plumbing idiot..so keep that in mind. The contractor that built and plumbed my house had put the circulator (1 zone ranch at that time) on the return side of the boiler. Said 50% like the pump on the supply side and 50% like the pump on the return side. He was always taught return. Old school!

Recently he has been telling me I should move the pump to the supply side because industry has been finding that if you run a mixing valve between the supply and return and run 150 deg water through the baseboard, there is a significant cost savings. The boiler would still produce 180 deg water. To do this he said the pump has to be on the supply side.

Point is, prior to buying a gasser I planned on making this plumbing change. It may still be worth doing for the non gassifier transition month(s). Just wondering if anyone had heard of the benefit of mixing supply/return and running lower temps through the baseboard?

150 °F may be getting a tad low. Ideally the baseboard lengths were sized to keep the rooms warm, let's say 70 °F on a design day. Design being the coldest expected temperature in your area, call it -15F. Often systems are was designed around 180F boiler supply temperature. So on milder days 150F may be enough temperature to give the baseboards enough energy, but I doubt on a cold winters day. UNLESS they oversized the amount of baseboards in the rooms.

There is a movement on to design systems around lower supply temperatures, but the emitters need to be sized for those lower temperatures.

An outdoor reset control, ODR is a means that could allow the boiler or mixing valve to adjust it's temperature going out to the baseboard based on outdoor temperature. The colder it gets outside, the hotter the water to the system. That type of control could save on operating cost.

Your installers proposed method could also, but you may need to adjust it manually as it gets colder outside. Ask him about a control with ODR capability. Then the system would automatically adjust.

hr

hr

btuser

Minister of Fire

Tekmar 260 will do DHW. Intellicon will modulate boiler temp and adjust differential. Piece of cake.

The contractor did mention to me about using a multi speed circulator with the mixing system. No outdoor temp probe but utilizing a "Heat Manager" Processor. You may be familiar with it but it more or less learns the patterns quick of how often your boiler needs to fire(excluding DHW). Basically it delays your boiler from firing until it uses most of the hot water it already made. Reduces firing cycles but not to the point where you're wanting for heat.

I actually installed a heat manager but honestly can't tell you whether it was worth it or not yet. I am tracking recorded temps in my area but not enough data to determine whether it saved me what it claims it would.

Now comes the wood boiler so I have to re-evaluate the heat manager controls.

Also not to sound any more heating ignorant than I am, What is a mod-con boiler?

I actually installed a heat manager but honestly can't tell you whether it was worth it or not yet. I am tracking recorded temps in my area but not enough data to determine whether it saved me what it claims it would.

Now comes the wood boiler so I have to re-evaluate the heat manager controls.

Also not to sound any more heating ignorant than I am, What is a mod-con boiler?

jimmie ray

New Member

A mod-con boiler modulates the fuel input, and condenses the flue gas within the heat exchanger to extract additional energy from the fuel. The best performance is achieved when the air / fuel ratio is maintained throughout the modulation (typically 4:1), and the return water temp is kept low for the flue gasses to below the dewpoint (140* F or so, depends on CO2). Both aspects of this technology are not fully developed for oil firing yet - at least not that I know of in the USA.

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 693

- Replies

- 9

- Views

- 2K

- Replies

- 10

- Views

- 2K

- Replies

- 6

- Views

- 600