nhtreehouse

Member

so with the propane tanks i don't have to worry about rust since they are much thicker?

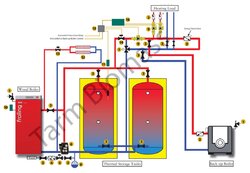

Yes. My 1000 gallon tank is 5/16" thick on the cylinder and 1/4" thick on the heads. It should weigh in at around 1800 lbs. In comparison, oil tanks are measured in gauge, not inches. I'm sure someone here knows how thick they are, but a guess would be 14 gauge. That's a bit over 1/16". Pressure is no problem with propane tanks as they are originally built for something like 250 PSI. Another important fact is that with a propane tank you can run the system pressurized without a heat exchanger, as others have commented on here.

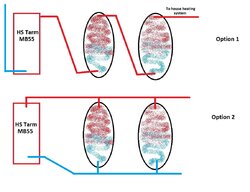

Other members have cut propane tanks down and used multiple tanks for tight locations. It works.

I put together a simple spreadsheet to calculate tank volume. Using that tool, I come up with about 277 gallons per tank if you start with a 500 gallon tank which is typically 37" in diameter, and cut it down to 6' length overall. That assumes the heads/ends are hemispheres which is not always the case. Your mileage may vary here. Happy to share the spreadsheet - just PM me.