I ordered an econoburn 200 and I have a 1000 gallon lp tank that I will be getting.

I did have the guy add four ports to the tank. They are 2" top and bottom both ends.

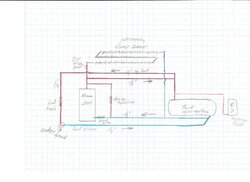

I currently have an OWB that has a Primary/ Secondary manifold in my garage that is 115' from where the boiler house will be. I am trying to grasp how this is all going to lay out and this is what I would like to do.

Run my current Primary/Secondary setup as the load side and connect the econoburn/ storage tank to my underground pipe using something similar to the Simple pressurized storage sticky that Nofossil has posted.

Could you guys look at this basic drawing and tell me if I am headed in the right direction or totally off base?

One thing I am wondering is how to control ghost flow when I am using circulators for my load side instead of zone valves. Can I add a zone valve to open when the call for heat is sent to the load circulator?

gg

I did have the guy add four ports to the tank. They are 2" top and bottom both ends.

I currently have an OWB that has a Primary/ Secondary manifold in my garage that is 115' from where the boiler house will be. I am trying to grasp how this is all going to lay out and this is what I would like to do.

Run my current Primary/Secondary setup as the load side and connect the econoburn/ storage tank to my underground pipe using something similar to the Simple pressurized storage sticky that Nofossil has posted.

Could you guys look at this basic drawing and tell me if I am headed in the right direction or totally off base?

One thing I am wondering is how to control ghost flow when I am using circulators for my load side instead of zone valves. Can I add a zone valve to open when the call for heat is sent to the load circulator?

gg