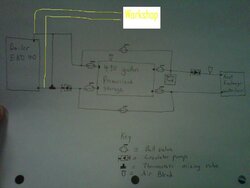

With EW's suggested change on the shop plumbing, this is the way my system is plumbed and what I also would recommend. I agree that the bypass valves do not provide much advantage; even a horizontal tank stratifies very well with this setup. But, the higher temp boiler return mixing valve may not achieve the intended result of higher temp water to the wahx. The result also will depend on flow rates and bottom of storage temperature. If we assume the Eko has average output of 100,000 btuh, at deltaT of 20F, that is 10 gpm. The boiler return mixing valve will divert some of that output back to the boiler to maintain the set temp of the boiler return mixing valve, so actual flow to storage will be less than 10 gpm until all of storage is up to the set temp. The higher the set temp, the longer it will take to bring all of storage up to the set temp so that full 10 gpm flow goes to storage.

Next is the gpm flow through the wahx. If the flow is greater than the boiler circ flow to storage, maximum temp to the wahx will be a mix of boiler output/top of tank temp and lower tank temp based on the stratification within the tank, but it can't be the set temp of the boiler return mixing valve because more flow is required than boiler output to storage.

Another factor will be the return temperature from the wahx. Assuming a deltaT of 20F and 180F supply to the wahx, return to bottom of tank will be 160F, and there will be relatively rapid mixing of the tank to the wahx return temp. This mixing will affect boiler operation because now bottom of tank (assume possible 160F from wahx) water is now much warmer than from a bottom of a stratified tank with no mixing occurring. This is not necessarily bad, but it will make it important to make sure that the boiler circ is gpm-sized to handle boiler output based on expected storage return temperature.

Everything I have said does not change EW's affirmation of your plumbing plan, with which I agree. I'm not sure, however, that you will necessarily gain any system performance from a 180F vs. 160F boiler return mixing valve. The performance gain, if any, will depend on the flow rate of your wahx system, which likely will be increased when the shop loop is added.

Lastly, it would be very good if your wahx really doesn't need 180F water to meet your comfort requirement heat demand. As you likely are well aware, if that is the requirement, your storage will be of limited help in extending times between burns. Assuming the maximum temp your boiler will deliver is 190F, storage btu's from 10F in a 490 gallon tank is only about 40,000 btu's, which won't heat most houses for long in cold weather.

As said, EW's comments are solid. I really like the idea of plumbing storage as a hydraulic separator. It is simple, efficient, and can work very well.