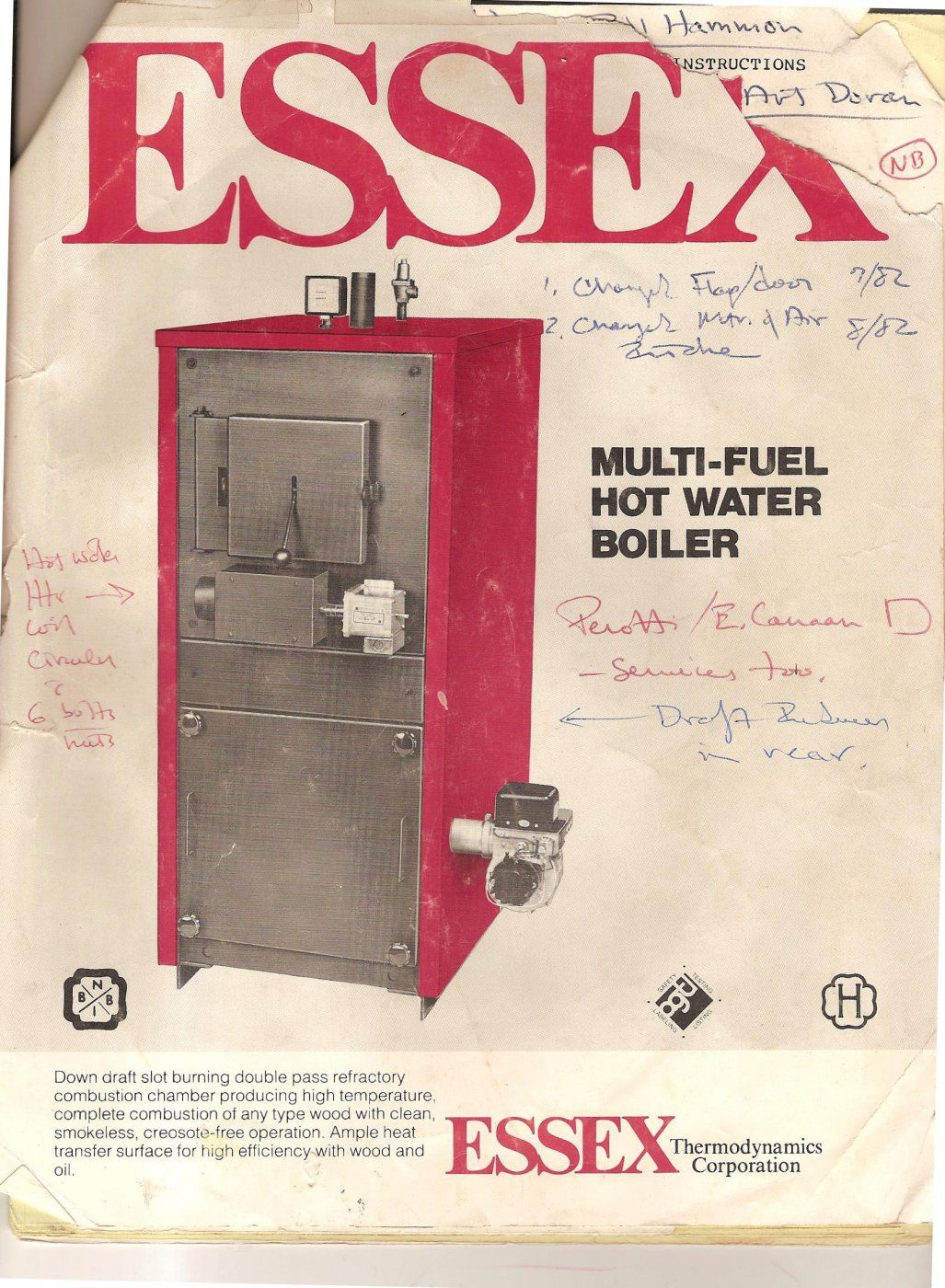

I have been getting quotes to replace the big dual-fuel boiler that came with my house when I bought it. It's an Essex Thermodynamics and it was installed in 1981. It can't be efficient, right? We ran it on oil for the first two winters here because the wood side didn't seem to work. As I'm sure you all know, oil is rediculously expensive. We decided to get rid on it. Being a fairly new home owner faced with the huge cost to replace it, I decided to do a little research on Essex. I happened to come across the owner Manny Pacheco's number in an old post on Hearth.com. With nothing to lose I tried to call him. Manny answered the phone on my call and came over the very next day to look at her. Over the years the previous owners had stripped parts off of it, so it did need work to get the wood side going. But, for a very reasonable price Manny had my boiler up and running 100% wood which is going to save me thousands this winter. He took the time to explain how the gasification process works, something the others copied from Essex. I am so glad I didn't replace it. I'm actually looking forward to when it's cold enough to run full time (a first for me!). I highly recommend Essex for anyone in the market for a dual-fuel boiler. After you look at Tarm and Wood Gun, give Manny a call 978-870-6599. Tell him Damian sent you!

Essex Thermodynamics are still around

- Thread starter luvmydamian

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Gasifier

Minister of Fire

I did not know Essex was still around. I know a guy who has one. Burns wood through it. Will not burn oil through it, even though he has the option. I will let him know about this. Thanks.

yes let them know also they should get an easy 85% on oil but get a riello burner and they will do even better

lavs4x4

New Member

Glad I'm not the only one running an essex still! Also glad Manny is still around selling parts for these units. I was just thinking about giving him a call and ordering up some new inserts, and refractory blocks. Overall, I have been very happy with the unit, heats my 4300 sqft farmhouse in central maine without any issues. Getting to know how the unit works, load timing, and regular cleaings will keep you warm and toasty with relatively low inconvience.

BennoTron

New Member

Glad I'm not the only one running an essex still! Also glad Manny is still around selling parts for these units. I was just thinking about giving him a call and ordering up some new inserts, and refractory blocks. Overall, I have been very happy with the unit, heats my 4300 sqft farmhouse in central maine without any issues. Getting to know how the unit works, load timing, and regular cleaings will keep you warm and toasty with relatively low inconvience.

I don't suppose anyone has had any luck getting a hold of Manny? I've been trying since January and he doesn't answer e-mails or phone calls. I am in DIRE need of inserts, that ceramic fiber disc insulation from the door of the refractory, some gaskets, screw handles, etc. If I don't eventually hear back from him, I'm going to have to replace my Essex 1000 before next heating season.

Please?

Benno

Gasifier

Minister of Fire

I don't know anyone who has been getting ahold of this guy. But the guy I know who still heats with an Essex went through the process of making his own inserts. He bought a material that you mix yourself and made his own cast. Formed them, cured them and placed them in his boiler. He has had them in there for two seasons now I think. If you can not get ahold of Manny, you could look into fixing your Essex yourself. Especially now that you have some time before next heating season.

BennoTron

New Member

Strangely enough, after having no luck and calling and e-mailing for quite a while, I did get a hold of Manny this morning, calling at 8am central, 9am Manny-time. He still has the parts, and says that the fax machine is the way to submit an order as he's been having computer issues. I contacted him successfully at the cell phone number listed above by luvmydamian.

Thanks,

Benno

Thanks,

Benno

BennoTron

New Member

I don't know anyone who has been getting ahold of this guy. But the guy I know who still heats with an Essex went through the process of making his own inserts. He bought a material that you mix yourself and made his own cast. Formed them, cured them and placed them in his boiler. He has had them in there for two seasons now I think. If you can not get ahold of Manny, you could look into fixing your Essex yourself. Especially now that you have some time before next heating season.

That's dedication! Unfortunately, I don't have a lot of casting experience, but I was able to reproduce much of the functionality of the inserts by creating similarly-sized openings by laying fire brick across the insert area, leaving gaps of an inch every few bricks, and that keeps me running for now, but the circular ceramic-fiber board insulation as well as the caulk that holds it to the refractory door has degraded severely enough that I'd be nervous burning wood in it. I've also had some minor creosote build-up in my chimney and firebox, which I am told means I need to replace every gasket and seal I can find to make the unit more air-tight, thereby increasing its efficiency and making it burn cleaner, so I'm trying to get rubber and rope gaskets, insulation, screw knobs, inserts, etc. I was extremely pleased to find Manny today.

Thanks for the quick response,

Benno

heaterman

Minister of Fire

This thread is worthless without pictures.

Don't recall ever seeing that brand in this neck of the woods but it sounds interesting.

Don't recall ever seeing that brand in this neck of the woods but it sounds interesting.

charlie9462

New Member

Glad I'm not the only one running an essex still! Also glad Manny is still around selling parts for these units. I was just thinking about giving him a call and ordering up some new inserts, and refractory blocks. Overall, I have been very happy with the unit, heats my 4300 sqft farmhouse in central maine without any issues. Getting to know how the unit works, load timing, and regular cleaings will keep you warm and toasty with relatively low inconvience.

I can get the refractory blocks if anyone needs them. Half the cost of originals!! I also heated my house and domestic hot water for seven years on a 1980 model. I now have a 1990 and it runs great. I have had to weld a few leaks over the years and replaced the Refractory blocks once. I replace the center ones every two years. My 1990 has been running for 5 years. I heat my pool also. If anyone wants solid advice shoot me an email.

[email protected]

Yes my name is Charlie.

STIHLY DAN

Minister of Fire

charlie9462

New Member

they are out of business but I can get the refractory bricks an a few parts. There is no way to get 85% with oilDo they still make the Essex? Or are they just supplying parts?

max bob

New Member

We have Essex boiler refractorys instock now along with other parts. Will not be producing refractory again until 2016. Call Bob P. AT (978)-870-6537. PS STILL IN BUSINESS

univet

New Member

I have an Essex Boiler (Model #222 made in 1978-79) which was installed in 1979 and still in use. I am presently using the oil feature just for domestic hot water as I have a central chimney with a wood stove which heats my whole house (salt box). I did use it for wood for about 10 years and replaced the hearth once and haven't used it since. The wood mode was very efficient though and if set to cycle every few hours (I believe it was 3 hours or so) it would re-ignite and run beautifully. I used 9 cord of wood and now with my wood stove I'm down to 4-5 cord or less.

Just recently the Essex hot water coil has a very small leak and the pressure in the furnace chamber elevates ever so slowly and when after a few weeks it reaches 35-40# I drain it back down to the 10# range. I AM LOOKING FOR A WAY TO REPAIR THE COPPER COILS OR GET A NEW HOT WATER COIL IF I COULD .... OR A USED ONE IF ANYONE HAS THEM. Still love this boiler and am not looking forward to the day when I might have to replace it.

Just recently the Essex hot water coil has a very small leak and the pressure in the furnace chamber elevates ever so slowly and when after a few weeks it reaches 35-40# I drain it back down to the 10# range. I AM LOOKING FOR A WAY TO REPAIR THE COPPER COILS OR GET A NEW HOT WATER COIL IF I COULD .... OR A USED ONE IF ANYONE HAS THEM. Still love this boiler and am not looking forward to the day when I might have to replace it.

univet

New Member

Thanks for the suggestion krinkov. I'll keep it in mind as an option. I shut the coil down when not in use for the last 48 hours and it seems to have temporarily plugged the ultra fine leak thus far! We'll see - it's been open again now for 24 hours and pressure staying at 20#. The coupler sounds good "if" we can find the leak (Water pressure in my domestic hot water system is 40-60psi). I'm sure we could pump a dye through the tubing and find it, but I worry about the whole thing being prone to leaking. Might be able to rework the tubing with new tubing. Time will tell.

univet

New Member

Here's where we are on the Hot Water Coil issure. I contacted Robert Pacheco (978-870-6537) - left a message one day and got Bob the next evening answering the phone "ESSEX". I explained my Hot Water Coil problem and he said: "Call Triangle Tube in PA and they'll make one up for you". I actually found the Model number on my Coil Plate (Model #15-A). Well ... This AM I called Triangle Tube for some bad news - they chucked all the equipment for making the coils 6 years age. They did say that a company in NY could fabricate one for me (Diversified Heat Transfer - http://www.dhtnet.com/ ... Tel. 820-221-1522). Seeing as I have to pull the unit anyway to measure it and get a few pictures, I contacted a friend who says we can pressurize it with air to find the leak and solder it. So that's where I stand on the issue at the moment. Will post an update later.

- Status

- Not open for further replies.

Similar threads

- Replies

- 11

- Views

- 993

- Replies

- 3

- Views

- 315

- Replies

- 12

- Views

- 3K

- Replies

- 41

- Views

- 4K