What is generally considered the best method for felling a mature oak tree? I.E. is the traditional 45 degree pie appropriate, or is the wider 90 better? On the back cut, do you still recommend coming down on it, or do you now prefer the back cut to come into the hinge parallel to the ground?

Felling a tree

- Thread starter G6 at Snook TX

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

smokinj

Minister of Fire

red oak

Minister of Fire

smokinj

Minister of Fire

red oak said:Why parallel to the ground for the back cut?

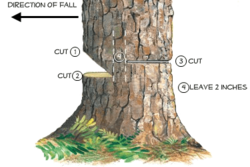

Just the way I was taught. Wedge that back cut. Sometimes it can take quite a few!

Attachments

ansehnlich1

Retired Hearth.com Member

so, maybe I'll not make big points with this post, but if you are coming on an internet website to determine how to fell a mature oak you might want to consider hiring someone with experience to do so for you.

Kenster

Minister of Fire

First of all, let's give new members credit for asking questions and trying to learn something. Not all of us were born with a chain saw in one hand and a copy of "To Fell a Tree" in the other. We all had to learn somewhere, why not here? I grew up in the West Texas Panhandle. There were no trees out there. My dad didn't teach me how to operate a chain saw because he never used one. I have more trees on my property now than existed in our whole county where I grew up. (maybe slight exaggeration.)

If he hires someone to do the job for him he'll never learn.

I suspect the tree in question is not the first one G6 has ever felled. He's just checking his technique with the members here. The first tree I ever dropped was a huge Water oak that had been struck by lightning. I read a little bit about felling trees and took my little cheapo Sears 16 inch to the 30 inch diameter trunk. My cuts were far from perfect and I actually had to whittle it down quite a bit but I learned enough from this site to know how to practice safe sawing. I had my escape routes planned and was constantly watching that trunk- should it decide to fall in a direction I had not planned. It eventually started tipping over and fell precisely where I wanted it to- not entirely by accident. I was cutting in an open area in my woods and there was no danger of the tree falling into wires or another building. I learned enough by reading 100s of threads that I was reasonably confident that I could do the job safely. I've since felled several trees and I'm still learning how to make my cuts. I had one tree last winter that fell exactly 180 degrees from where I wanted it, but I still operated safely. To this day I would never attempt to fell a tree close to a building or power lines.

Let's encourage new members to learn all they can and do things safely with good equipment, while cautioning them to know their limits, too.

If he hires someone to do the job for him he'll never learn.

I suspect the tree in question is not the first one G6 has ever felled. He's just checking his technique with the members here. The first tree I ever dropped was a huge Water oak that had been struck by lightning. I read a little bit about felling trees and took my little cheapo Sears 16 inch to the 30 inch diameter trunk. My cuts were far from perfect and I actually had to whittle it down quite a bit but I learned enough from this site to know how to practice safe sawing. I had my escape routes planned and was constantly watching that trunk- should it decide to fall in a direction I had not planned. It eventually started tipping over and fell precisely where I wanted it to- not entirely by accident. I was cutting in an open area in my woods and there was no danger of the tree falling into wires or another building. I learned enough by reading 100s of threads that I was reasonably confident that I could do the job safely. I've since felled several trees and I'm still learning how to make my cuts. I had one tree last winter that fell exactly 180 degrees from where I wanted it, but I still operated safely. To this day I would never attempt to fell a tree close to a building or power lines.

Let's encourage new members to learn all they can and do things safely with good equipment, while cautioning them to know their limits, too.

firefighterjake

Minister of Fire

+1 Kenster . . .

With a few caveats . . . it always helps to start off cutting with someone who knows what they are doing and can show you the ropes so to speak . . . and it's often easier to start with smaller trees than a monster tree . . . not that the small ones can't kill or injure you as easily . . . it's just that if you pinch a saw or need to give a tree a push in the right direction it's easier with small trees than the big ones.

With a few caveats . . . it always helps to start off cutting with someone who knows what they are doing and can show you the ropes so to speak . . . and it's often easier to start with smaller trees than a monster tree . . . not that the small ones can't kill or injure you as easily . . . it's just that if you pinch a saw or need to give a tree a push in the right direction it's easier with small trees than the big ones.

Woody Stover

Minister of Fire

We all had to learn at some point. Perhaps you have an experienced acquaintance who could drop it for you and give you some pointers. Or you can check your local library for information. You can probably also find info at any number of internet websites. :lol: A beginner should only attempt very straight-forward falls, and of course wear protective gear. Take the tree in the direction it wants to go, and there should be a large open landing area. If it's hitting other trees on the way down, potential dangers lurk. It could also hang up, which is a nightmare. The trunk should be solid wood; If you see dark chips coming out of the cut, look out! When it starts to go, get the hell away at a 45* angle on your cleared escape route, don't stand next to the trunk admiring your handiwork! Be safe, and good luck!ansehnlich1 said:if you are coming on an internet website to determine how to fell a mature oak you might want to consider hiring someone with experience to do so for you.

JustWood

Minister of Fire

red oak said:Why parallel to the ground for the back cut?

Because it's easier to line up the back cut with your bottom notch cut and NOT cut through the hinge.

Thistle

Minister of Fire

Kenster said:First of all, let's give new members credit for asking questions and trying to learn something. Not all of us were born with a chain saw in one hand and a copy of "To Fell a Tree" in the other. We all had to learn somewhere, why not here? I grew up in the West Texas Panhandle. There were no trees out there. My dad didn't teach me how to operate a chain saw because he never used one. I have more trees on my property now than existed in our whole county where I grew up. (maybe slight exaggeration.)

If he hires someone to do the job for him he'll never learn.

I suspect the tree in question is not the first one G6 has ever felled. He's just checking his technique with the members here. The first tree I ever dropped was a huge Water oak that had been struck by lightning. I read a little bit about felling trees and took my little cheapo Sears 16 inch to the 30 inch diameter trunk. My cuts were far from perfect and I actually had to whittle it down quite a bit but I learned enough from this site to know how to practice safe sawing. I had my escape routes planned and was constantly watching that trunk- should it decide to fall in a direction I had not planned. It eventually started tipping over and fell precisely where I wanted it to- not entirely by accident. I was cutting in an open area in my woods and there was no danger of the tree falling into wires or another building. I learned enough by reading 100s of threads that I was reasonably confident that I could do the job safely. I've since felled several trees and I'm still learning how to make my cuts. I had one tree last winter that fell exactly 180 degrees from where I wanted it, but I still operated safely. To this day I would never attempt to fell a tree close to a building or power lines.

Let's encourage new members to learn all they can and do things safely with good equipment, while cautioning them to know their limits, too.

+10 Precisely. We all had to learn sometime.Using common sense,good equipment,safely thought out procedures will help you in so many ways.Just take it slow & dont try to do something you dont feel comfortable with.We can all benefit from each other's knowledge, experiences & history,that's what we're here for.

Thistle

Minister of Fire

smokinjay said:red oak said:Why parallel to the ground for the back cut?

Just the way I was taught. Wedge that back cut. Sometimes it can take quite a few!

You got it Jay.Taught the same way myself. Plus ropes,cable,winch etc in certain cases if need be.

I ask because I have read a couple of books on felling trees, and know the basic procedures and safety habits, but there has been some disagreement I have seen on the wedge cut 45* vs. 90* and whether or not bring the back cut in and down to the hinge or parallel. It seems mostly old practice vs. new practice.

Kenster

Minister of Fire

G6 at Snook said:I ask because I have read a couple of books on felling trees, and know the basic procedures and safety habits, but there has been some disagreement I have seen on the wedge cut 45* vs. 90* and whether or not bring the back cut in and down to the hinge or parallel. It seems mostly old practice vs. new practice.

I'm not sure how much difference it makes whether you cut the face cut at 45 up to 90 degrees. But most everything I've ever read or heard says to make the back cut parallel and a bit above the face cut so you will have a good hinge.

I claim no expertise in this.

JustWood

Minister of Fire

A 90 degree notch will not close up and break your hinge off till the tree hits the ground = full side to side control of the tree.

Kenster

Minister of Fire

uncontrolabLEE said:A 90 degree notch will not close up and break your hinge off till the tree hits the ground = full side to side control of the tree.

A 45 degree cut wouldn't close until the tree is parallel with the ground. Wouldn't that be just as good? I'm asking because I don't know. Just trying to learn.

And isn't there something call a Humbolt cut, or something like that? A 45 degree cut with the angle cut below the horizontal cut? How does that work?

Thistle

Minister of Fire

Kenster said:uncontrolabLEE said:A 90 degree notch will not close up and break your hinge off till the tree hits the ground = full side to side control of the tree.

A 45 degree cut wouldn't close until the tree is parallel with the ground. Wouldn't that be just as good? I'm asking because I don't know. Just trying to learn.

And isn't there something call a Humbolt cut, or something like that? A 45 degree cut with the angle cut below the horizontal cut? How does that work?

Humboldt cut is normally used on western softwoods,especially those growing on slopes.It was done with hand tools years ago because it was thought to help the tree to 'slide' down away from the stump.Today mills prefer it because it leaves a square cut on the butt log. The lower cut of the 'pie' is in the stump that's left,instead of being in the upper part of the butt log.

Here's one example,good sized Alaskan Yellow Cedar

http://www.youtube.com/watch?v=V-SwpDKkHko&feature=related[/youtube]

smokinj

Minister of Fire

Thistle said:Kenster said:uncontrolabLEE said:A 90 degree notch will not close up and break your hinge off till the tree hits the ground = full side to side control of the tree.

A 45 degree cut wouldn't close until the tree is parallel with the ground. Wouldn't that be just as good? I'm asking because I don't know. Just trying to learn.

And isn't there something call a Humbolt cut, or something like that? A 45 degree cut with the angle cut below the horizontal cut? How does that work?

Humboldt cut is normally used on western softwoods,especially those growing on slopes.It was done with hand tools years ago because it was thought to help the tree to 'slide' down away from the stump.Today mills prefer it because it leaves a square cut on the butt log. The lower cut of the 'pie' is in the stump that's left,instead of being in the upper part of the butt log.

Here's one example,good sized Alaskan Yellow Cedar

http://www.youtube.com/watch?v=V-SwpDKkHko&feature=related[/youtube]

Heck now I am confused...Can we now do the plunge felling....lol

JustWood

Minister of Fire

Kenster said:uncontrolabLEE said:A 90 degree notch will not close up and break your hinge off till the tree hits the ground = full side to side control of the tree.

A 45 degree cut wouldn't close until the tree is parallel with the ground. Wouldn't that be just as good? I'm asking because I don't know. Just trying to learn.

And isn't there something call a Humbolt cut, or something like that? A 45 degree cut with the angle cut below the horizontal cut? How does that work?

45 is closed half way to the ground and hinge is broke off stump.

uncontrolabLEE said:...45 is closed half way to the ground and hinge is broke off stump.

That's what trigonometry tells me. Cut a 45° notch, and that thing will be shut when the tree has fallen 45° from vertical on its way down. Then the hinge will be torn apart. Rick

smokinj

Minister of Fire

uncontrolabLEE said:Kenster said:uncontrolabLEE said:A 90 degree notch will not close up and break your hinge off till the tree hits the ground = full side to side control of the tree.

A 45 degree cut wouldn't close until the tree is parallel with the ground. Wouldn't that be just as good? I'm asking because I don't know. Just trying to learn.

And isn't there something call a Humbolt cut, or something like that? A 45 degree cut with the angle cut below the horizontal cut? How does that work?

45 is closed half way to the ground and hinge is broke off stump.

Learn something new everyday! Never thought about why. lol Guess what I was told, your dead if you dont...

bogydave

Minister of Fire

Good info.

I cut my notch just the opposite as SJ's picture. I angle up the bottom cut. I makes the butt round a more usable round, almost straight on both ends.

But the same results.

Straight across on the back cut allow for a wedge to be driven in better, if needed.

A good hinge is important for control. Some guys are real good & can use the hinge to twist the tree one way or the other, lots of practice helps.

Be safe! Have an exit path determined & cleared. Even the best get surprised. When it starts to go, be on your way out of there.

Some info here:

http://forestry.about.com/od/chainsaws/ss/fell_tree_5.htm

I cut my notch just the opposite as SJ's picture. I angle up the bottom cut. I makes the butt round a more usable round, almost straight on both ends.

But the same results.

Straight across on the back cut allow for a wedge to be driven in better, if needed.

A good hinge is important for control. Some guys are real good & can use the hinge to twist the tree one way or the other, lots of practice helps.

Be safe! Have an exit path determined & cleared. Even the best get surprised. When it starts to go, be on your way out of there.

Some info here:

http://forestry.about.com/od/chainsaws/ss/fell_tree_5.htm

smokinj

Minister of Fire

bogydave said:Good info.

I cut my notch just the opposite as SJ's picture. I angle up the bottom cut. I makes the butt round a more usable round, almost straight on both ends.

But the same results.

Straight across on the back cut allow for a wedge to be driven in better, if needed.

A good hinge is important for control. Some guys are real good & can use the hinge to twist the tree one way or the other, lots of practice helps.

Be safe! Have an exit path determined & cleared. Even the best get surprised. When it starts to go, be on your way out of there.

Some info here:

http://forestry.about.com/od/chainsaws/ss/fell_tree_5.htm

Thats because your left coast...lol

bogydave

Minister of Fire

I thought it was because I'm standing more upright, South to North. LOL :lol:

You guys down there are more bent over , East/ West & spinning at a faster speed.

Wonder how they do it in Australia, up-side down :lol:

You guys down there are more bent over , East/ West & spinning at a faster speed.

Wonder how they do it in Australia, up-side down :lol:

smokinj

Minister of Fire

bogydave said:I thought it was because I'm standing more upright, South to North. LOL :lol:

You guys down there are more bent over , East/ West & spinning at a faster speed.

Wonder how they do it in Australia, up-side down :lol:

I seen some videos of those guys...Wow and The wood is extremely hard.

JustWood

Minister of Fire

The Humbolt is used for many different reasons. It's used felling downhill or at an angle to downhill. Used on softwoods mainly. If you used it on eastern hardwoods on flat ground its a good way to get killed by "springback" or "stump jump". On softwoods felling on hilly ground the Humbolt causes the tree to be thrown away from the working area and also in the process of being "thrown" causes the limbs to be torn off the bottom of the tree making for less work for the feller and taking less power from the yarder while retrieving.

It's not used on hardwoods due to limb structure/strength and top log quality.

It's not used on hardwoods due to limb structure/strength and top log quality.

- Status

- Not open for further replies.

Similar threads

- Replies

- 16

- Views

- 1K