Filling and purging a new or remodeled system can be a frustrating process. To be able to "push" air from a piping system you need enough water flow to "plug the hole" and circulate the air back to the purge point. To do this adequatly you need a means to flow a good gpm into the system. if you have an automatic fill valve, most have a fast fill lever or mechanism. This allows a higher pressure, more gpm, to flow.

Even with a fast fill device you may need to break the system into pieces and flush one piping subset at a time. Isolation valves allow you to "valve off' sections to assure you have enough flow to properly purge the system. It is almost impossible to purge the entire system with a central fill and just one purge point. You just can't predict where the water will flow. Water will always find the shortest, less restrictive route back to the purge opening.

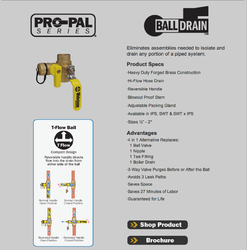

There are valves built specfically for that purpose that allow you to shut off the flow and provide a good hose connection to purge air.

If you are piping with primary secondary they also build a multi purpose valve to allow you to purge and pump from one fitting. Or build one with multiple valves and a hose cock.

Once you can establish flow, a central air purger will take care of smaller bubbles. The pump needs to circulate to finish the job, if the circ pump air locks you need to re-purge the system, you still have larger air pockets than the pump can move.

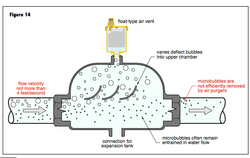

The older style cast iron ramp scoops work fairly well IF you can slow the flow enough for the air to rise to the upper portion and vent out. You want 18" of pipe up stream for the floe to straighten and slow for them to work well. They never get the tiny micro bubbles out unless the small bubbles meet up and form larger bubbles.

The newer style micro bubble devices all have a mesh or rings that capture the tiny bubbles and force them int larger bubbles to vent out.

These became very important with small passage way boilers and small id radiant tube, as small bubbles could cause no flow conditions and over heating in the boilers.

Small bubbles anywhere in the system will limit heat exchange as they cling to the metal surfaces.

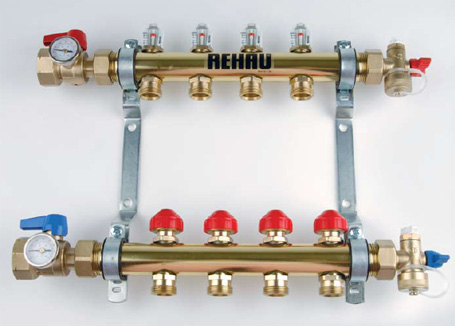

With large radiant zones it is helpful to valve one loop at a time for purging. This is critical if you have loops of different lengths. A manifold with individual shut offs at every branch helps.

Another common method to fast purge a system is connect a hose to the bottom of the boiler and allow the pressure to rise just below the relief valve setting, 28 psi or so.

It can take 20- 30 minutes to purge a large system. The more piping, HX coils, etc the longer it will take. Storage tanks with large arrays of copper coil can take some patients to purge, those should always have isolation and purge cocks in my opinion.

Use a short hose, like a wash machine hose on your purge valve. Put the loose end into a 5 gallon bucket of water to see the air bubbles come out. When it runs bubble free for 2- 3 minutes that zone is done. Valve it off and move to the next loop or zone.

But the key is properly placed isolation valves and purge cocks, it's hard to "over-valve" a mechanical room. the more you have the ability to isolate the quicker and more efficient the purge process will be. Here are some examples of speciality valves developed to help purging large systems.

There are a number of two in one devices, as shown that can do air and dirt removal. also some 3 in 1 that are hydraulic separators, dirt, and air removal in one box.

hr

Even with a fast fill device you may need to break the system into pieces and flush one piping subset at a time. Isolation valves allow you to "valve off' sections to assure you have enough flow to properly purge the system. It is almost impossible to purge the entire system with a central fill and just one purge point. You just can't predict where the water will flow. Water will always find the shortest, less restrictive route back to the purge opening.

There are valves built specfically for that purpose that allow you to shut off the flow and provide a good hose connection to purge air.

If you are piping with primary secondary they also build a multi purpose valve to allow you to purge and pump from one fitting. Or build one with multiple valves and a hose cock.

Once you can establish flow, a central air purger will take care of smaller bubbles. The pump needs to circulate to finish the job, if the circ pump air locks you need to re-purge the system, you still have larger air pockets than the pump can move.

The older style cast iron ramp scoops work fairly well IF you can slow the flow enough for the air to rise to the upper portion and vent out. You want 18" of pipe up stream for the floe to straighten and slow for them to work well. They never get the tiny micro bubbles out unless the small bubbles meet up and form larger bubbles.

The newer style micro bubble devices all have a mesh or rings that capture the tiny bubbles and force them int larger bubbles to vent out.

These became very important with small passage way boilers and small id radiant tube, as small bubbles could cause no flow conditions and over heating in the boilers.

Small bubbles anywhere in the system will limit heat exchange as they cling to the metal surfaces.

With large radiant zones it is helpful to valve one loop at a time for purging. This is critical if you have loops of different lengths. A manifold with individual shut offs at every branch helps.

Another common method to fast purge a system is connect a hose to the bottom of the boiler and allow the pressure to rise just below the relief valve setting, 28 psi or so.

It can take 20- 30 minutes to purge a large system. The more piping, HX coils, etc the longer it will take. Storage tanks with large arrays of copper coil can take some patients to purge, those should always have isolation and purge cocks in my opinion.

Use a short hose, like a wash machine hose on your purge valve. Put the loose end into a 5 gallon bucket of water to see the air bubbles come out. When it runs bubble free for 2- 3 minutes that zone is done. Valve it off and move to the next loop or zone.

But the key is properly placed isolation valves and purge cocks, it's hard to "over-valve" a mechanical room. the more you have the ability to isolate the quicker and more efficient the purge process will be. Here are some examples of speciality valves developed to help purging large systems.

There are a number of two in one devices, as shown that can do air and dirt removal. also some 3 in 1 that are hydraulic separators, dirt, and air removal in one box.

hr