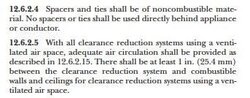

I am hoping someone can end my confusion about spacers for heat shields regarding reduced wall clearance to combustibles. Is there any NFPA code for approved materials that can be used for these spacers? I don't have access to this code book. I am so close to being able to install my stove with this being the last grey area. Is it one of of those things where there are no materials or methods specified, and many solutions will do? I'm hoping someone can look this up for me in the NFPA book. I have heard of the following, but no confirmation if any are required, allowed, or prohibited:

-1" ceramic spacers: seem to be discussed as if they are officially acceptable

-1" pieces of copper tubing: A DIY method that seems similar but a guy at the local stove dealer told me he wouldn't discuss because he never heard about it and wouldn't want to give me the wrong advice that could be the red flag if my house burnt down and the report listed "copper spacers used instead of ceramic"

-Strips of 1/2" cement board, doubled up: seemed like a good idea, so I cut all 20 strips needed. Now I worry these will transfer the heat right into the studs since that's where they will be mounted. Since they are solid vertical strips, this would allow much more space for heat transfer to the studs (if there even is any) than ceramic or copper spacers.

My setup:

Harman TL-300 stove

Modern Drywall & Stud wall

Reduced clearance heat shield of 1/2" Hardibacker cement board to be covered in thin stone, spaced 1" from wall, mounted into studs

One wall is exterior, the other is interior right over a steel I-beam under the floor, so the weight should be okay.

Clearance reductions are based on stove manual and then reduced by NFPA code of 66% reduction.

Thanks!

Tom

-1" ceramic spacers: seem to be discussed as if they are officially acceptable

-1" pieces of copper tubing: A DIY method that seems similar but a guy at the local stove dealer told me he wouldn't discuss because he never heard about it and wouldn't want to give me the wrong advice that could be the red flag if my house burnt down and the report listed "copper spacers used instead of ceramic"

-Strips of 1/2" cement board, doubled up: seemed like a good idea, so I cut all 20 strips needed. Now I worry these will transfer the heat right into the studs since that's where they will be mounted. Since they are solid vertical strips, this would allow much more space for heat transfer to the studs (if there even is any) than ceramic or copper spacers.

My setup:

Harman TL-300 stove

Modern Drywall & Stud wall

Reduced clearance heat shield of 1/2" Hardibacker cement board to be covered in thin stone, spaced 1" from wall, mounted into studs

One wall is exterior, the other is interior right over a steel I-beam under the floor, so the weight should be okay.

Clearance reductions are based on stove manual and then reduced by NFPA code of 66% reduction.

Thanks!

Tom