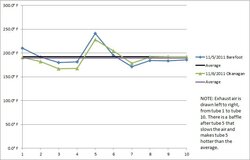

I have been burning 5 bags of Barefoots over the last couple of weeks and cleaned the stove good today, measured temps and ash content and am moving on to my Okies for the next couple of weeks. Very happy with the Barefoots. The first thing I noticed about the 1st bag of Okies is that they are very dusty and very short, at least compared to the Barefoots.

Dust all over and the pellets seemed to average about 1/4 inch in length and a high percentage of smaller bits of pellets. Not sure what defines a 'fine' but these seem small. I'm concerned about them even moving up the auger. It almost looks like someone took a 2x4 to the top of the pallet and crushed the top bag. Would this be considered normal for Okies? It's my first time with them. Maybe the top bags of the pallet were damaged?

They seem to be burning OK so far.

What defines a 'fine' anyway?

Dust all over and the pellets seemed to average about 1/4 inch in length and a high percentage of smaller bits of pellets. Not sure what defines a 'fine' but these seem small. I'm concerned about them even moving up the auger. It almost looks like someone took a 2x4 to the top of the pallet and crushed the top bag. Would this be considered normal for Okies? It's my first time with them. Maybe the top bags of the pallet were damaged?

They seem to be burning OK so far.

What defines a 'fine' anyway?