Hi,

I am a long time reader, but just joined and have a question / problem. Over this past winter my quest has gotten to the point the flame is very lazy. I have checked the exhaust pipe and cleaned it. I have readjusted the door to make sure the door closes tight. At this point the flame in the burn pot is worce than a candle burning in the room.

At this point I have to run the stove with the pellet feed on low and the damper control wide open to get the stove to produce any flame.

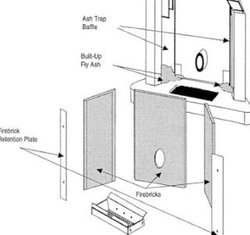

If I look under the burn pot there is a square hold that leads out the back of the stove. I cannot see anything that should block this hole. I don't understand the purpose of this hole.

In the past I have replaced the exhaust blower, auger motor (twice) auger, bushing and plate. This have improved the running of the stove, but this lazy flame has me stumped.

Can anyone help pinpoint my problem for me.

I am located in Western Maine (Oxford Hills area) and if someone can point me to a good serviceman to stop by that would be a big help.

thanks

Rick..........

I am a long time reader, but just joined and have a question / problem. Over this past winter my quest has gotten to the point the flame is very lazy. I have checked the exhaust pipe and cleaned it. I have readjusted the door to make sure the door closes tight. At this point the flame in the burn pot is worce than a candle burning in the room.

At this point I have to run the stove with the pellet feed on low and the damper control wide open to get the stove to produce any flame.

If I look under the burn pot there is a square hold that leads out the back of the stove. I cannot see anything that should block this hole. I don't understand the purpose of this hole.

In the past I have replaced the exhaust blower, auger motor (twice) auger, bushing and plate. This have improved the running of the stove, but this lazy flame has me stumped.

Can anyone help pinpoint my problem for me.

I am located in Western Maine (Oxford Hills area) and if someone can point me to a good serviceman to stop by that would be a big help.

thanks

Rick..........